The Side Effects of Anti-Seize and Torque

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

The Side Effects of Anti-Seize and Torque

This is a little off topic but still on topic. This morning I was installing a pressed on pulley on a chevy power steering pump. I never thought of using Anti-Seize on the threads of the installer or puller. Over the years I have broken several installers and pullers. I have also used many cuss words when using these tools.  To my delight the Anti- Seize made a huge difference it the time and torque it took to install the pulley. I use anti-Seize a good bit, but had never thought of using it on the threads on my pullers. So this really got me to thinking about torque values with things like the gland nut, the rear axle nuts. Does anyone know if it is better to use Anti-Seize on threads for true torque rather than dry threads? Also are there any threads on a VW that should not have Anti-Seize used on them and why?

To my delight the Anti- Seize made a huge difference it the time and torque it took to install the pulley. I use anti-Seize a good bit, but had never thought of using it on the threads on my pullers. So this really got me to thinking about torque values with things like the gland nut, the rear axle nuts. Does anyone know if it is better to use Anti-Seize on threads for true torque rather than dry threads? Also are there any threads on a VW that should not have Anti-Seize used on them and why?

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- raygreenwood

- Posts: 11907

- Joined: Wed Jan 22, 2003 12:01 am

As you will see in many of my posts...I am a 100% proponent of anti-sieze.

I use it on ALL suspension component bolts, brake caliper mounting bolts, brake cylinder mounting bolts, body part mounting bolts, door hinge mounting bolts, lug bolts etc. I use it for exhaust nuts of all types.

A few words odf warning. I spent years with a company whose products required stainless bolts and stainless nuts of the same material....with high torque values. Thats a recipe for instant galling and locking of the hardware. Their warrnty required the use eof AS compound. But...they very carefully researched over 50 different commercailly available anti-sieze compounds.

The ywere looking for what worked the best with their materials with teh elast amount of tirque change and the best combination of chemical resistance for their chemicals and for water resistance.

It just so happend to be Fel-Pro C5A....which is now owned by Loctite.

But....all anti-siezes change the torque value slightly. They found...that this also greatly matters how its applied. It shoudl be applied paper thin.

bear in mind that AS is NOT designed to be a lubricant orgrease. Its an anti-galling additive. Strictly put...its a soft, high temp metal compiund designed to be a barrier between like metals used in fastners. It should be applied as thinnly and evenly as possible.

The lubricant (oil) that carries the metals are dsigned to dissipate and evaporate leaving just the metals. On bolts of critical material and location.....or on bolts recieving torque values close to their design limit....you should test a bolt with and without AS to find how the torque is different.

Typically...we found that it changed the torque value on our products by about 3%. In other words....50 ft lbs would really actually be 51.5 Ft lbs.

Also...the metal composition of various AS compounds is specific. If you are using plated or coated materials and fasteners that are fastening to materials that are electrolytically different....you might be careful what compund you use. There are aluminum compunds, aluminum zinc, copper, copper aluminum etc.

The aluminum compunds are all I usually use when thread a bolt into aluminum,. They have smaller softer particles that wear threads less and the metallic charge will not be different. Steel bolts can use most any AS. The aluminum compounds are some of the best anti-corrosion.

Nickle AS is very expensive, and is generally what you want to use with disimilar metals...and especially in places that must remain copper free (other industries). they are also the highest temperature at 2600F.

Anti-sieze should be wiped off and reapplied when you pull out a bolt and find black powdery residue. Thats oxidized metal.

Anti-sieze!.....the K+Y of automotive work! Ray

I use it on ALL suspension component bolts, brake caliper mounting bolts, brake cylinder mounting bolts, body part mounting bolts, door hinge mounting bolts, lug bolts etc. I use it for exhaust nuts of all types.

A few words odf warning. I spent years with a company whose products required stainless bolts and stainless nuts of the same material....with high torque values. Thats a recipe for instant galling and locking of the hardware. Their warrnty required the use eof AS compound. But...they very carefully researched over 50 different commercailly available anti-sieze compounds.

The ywere looking for what worked the best with their materials with teh elast amount of tirque change and the best combination of chemical resistance for their chemicals and for water resistance.

It just so happend to be Fel-Pro C5A....which is now owned by Loctite.

But....all anti-siezes change the torque value slightly. They found...that this also greatly matters how its applied. It shoudl be applied paper thin.

bear in mind that AS is NOT designed to be a lubricant orgrease. Its an anti-galling additive. Strictly put...its a soft, high temp metal compiund designed to be a barrier between like metals used in fastners. It should be applied as thinnly and evenly as possible.

The lubricant (oil) that carries the metals are dsigned to dissipate and evaporate leaving just the metals. On bolts of critical material and location.....or on bolts recieving torque values close to their design limit....you should test a bolt with and without AS to find how the torque is different.

Typically...we found that it changed the torque value on our products by about 3%. In other words....50 ft lbs would really actually be 51.5 Ft lbs.

Also...the metal composition of various AS compounds is specific. If you are using plated or coated materials and fasteners that are fastening to materials that are electrolytically different....you might be careful what compund you use. There are aluminum compunds, aluminum zinc, copper, copper aluminum etc.

The aluminum compunds are all I usually use when thread a bolt into aluminum,. They have smaller softer particles that wear threads less and the metallic charge will not be different. Steel bolts can use most any AS. The aluminum compounds are some of the best anti-corrosion.

Nickle AS is very expensive, and is generally what you want to use with disimilar metals...and especially in places that must remain copper free (other industries). they are also the highest temperature at 2600F.

Anti-sieze should be wiped off and reapplied when you pull out a bolt and find black powdery residue. Thats oxidized metal.

Anti-sieze!.....the K+Y of automotive work! Ray

-

helowrench

- Posts: 1925

- Joined: Wed Aug 11, 2004 6:20 am

- Lew

- Posts: 529

- Joined: Tue Feb 24, 2009 6:42 am

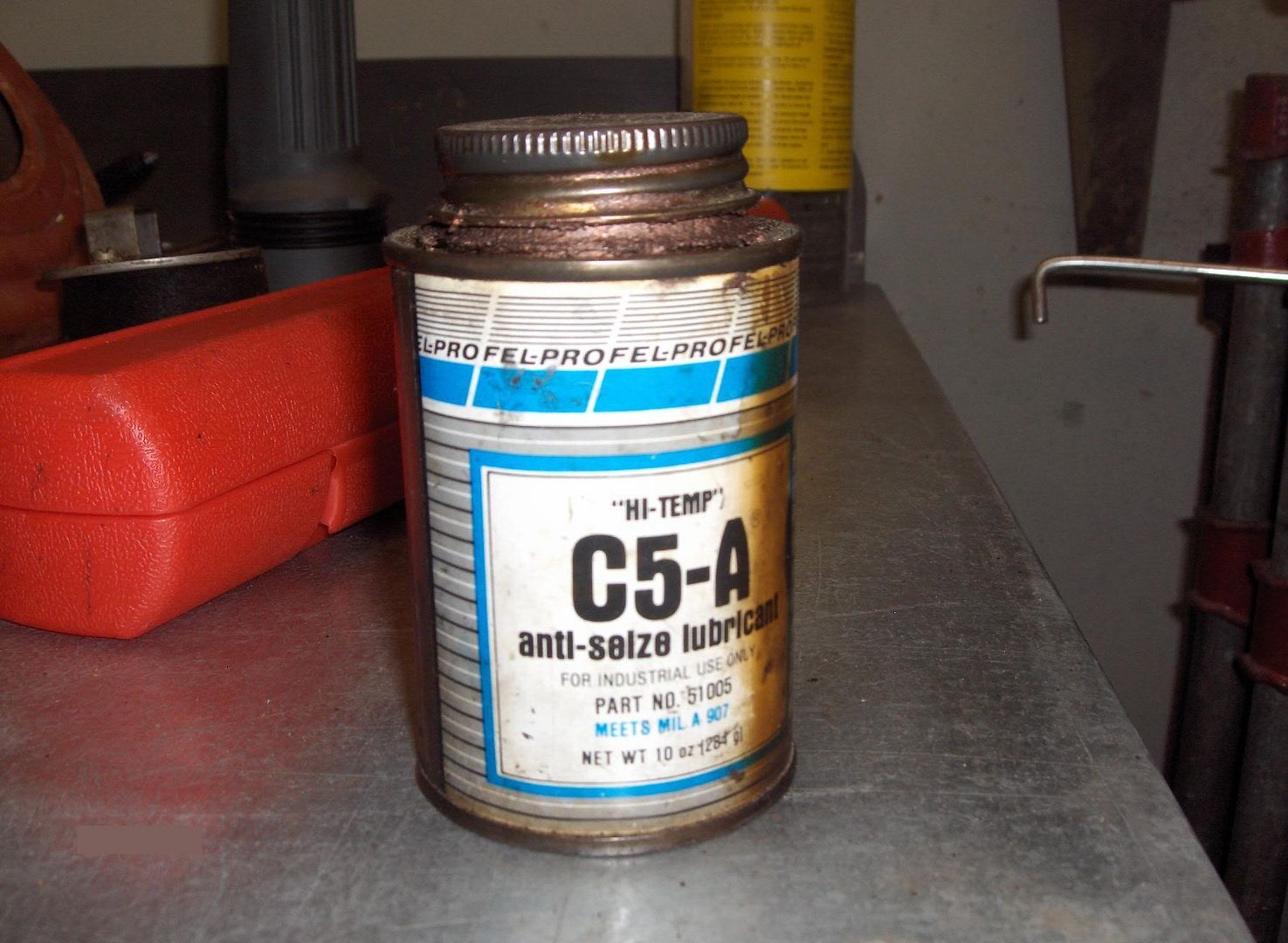

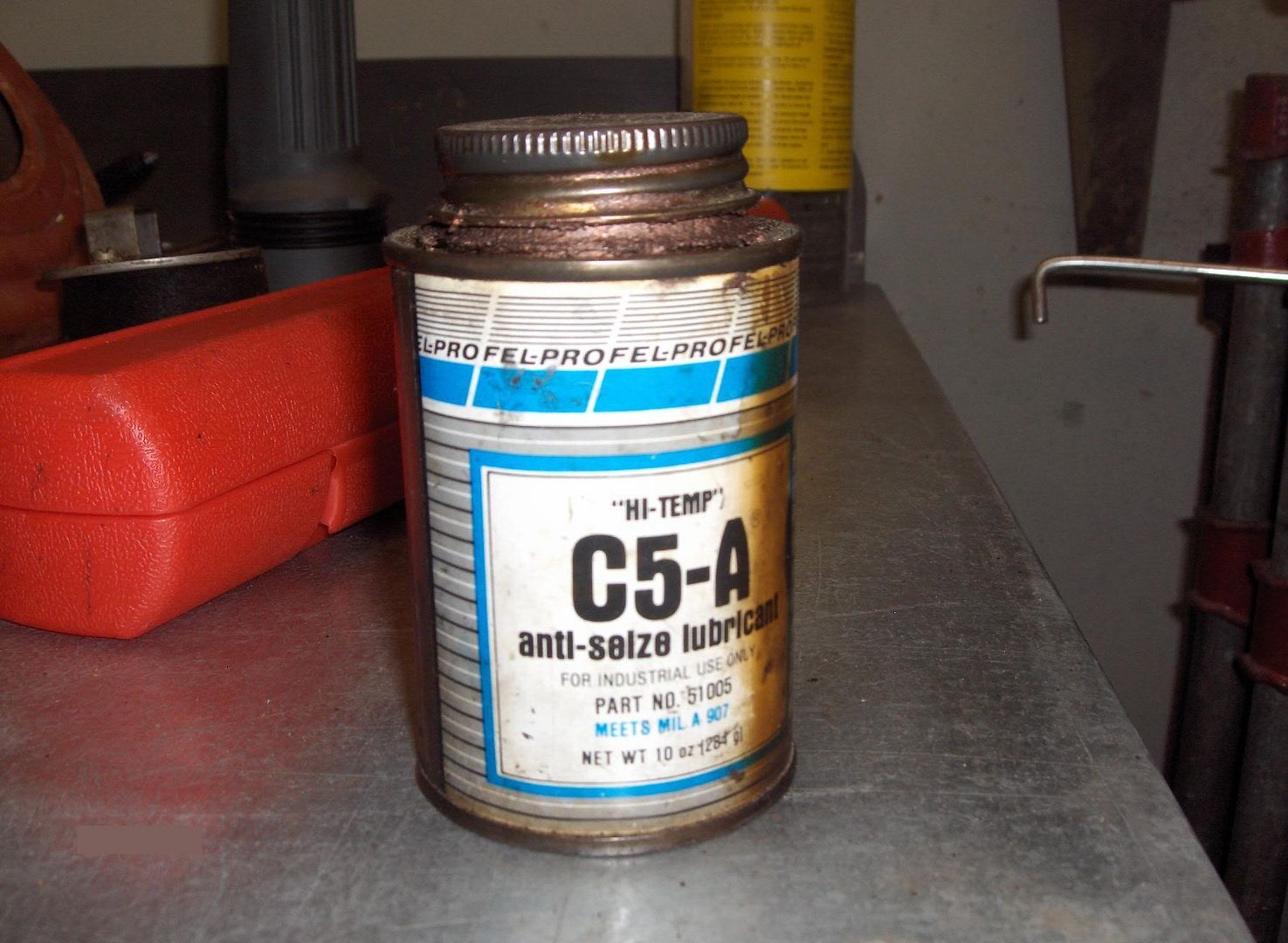

I am a big believer of this product on most all threaded applications. I have had this can for years. As Ray says apply thinly and let it do it's job.....Great stuff!

It's still in the Restoration Booth!

You can take a peek!

VW Help

VW Technial

Track Gas Mileage

The Class I Teach

You can take a peek!

VW Help

VW Technial

Track Gas Mileage

The Class I Teach

- bajaherbie

- Posts: 9967

- Joined: Sat Jul 15, 2006 7:07 pm

-

landrocket

- Posts: 180

- Joined: Fri Dec 12, 2008 5:31 pm

With my limited experience on bugs, but many years in aviation, unless it says to torque the fastener dry, anti-seize may be used. Just my two cents, personally, I put the stuff on everything and have never had a problem. The only time it sucks is when the P.O. or mechanic did not use it, that a 10 minute job took all day. Actually, if you think about it, dry threads are more prone to a false torque, due to friction and the same could be said about using WAY too much lube. Feel free to correct me, if I am off base on this.

- Lew

- Posts: 529

- Joined: Tue Feb 24, 2009 6:42 am

I did want a close up so the label would be readable. Only a 10 oz can mate!

Go here for a smaller picture Herbie!

Go here for a smaller picture Herbie!

It's still in the Restoration Booth!

You can take a peek!

VW Help

VW Technial

Track Gas Mileage

The Class I Teach

You can take a peek!

VW Help

VW Technial

Track Gas Mileage

The Class I Teach

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

As hinted at here, there is no one single answer to fastener installations. Some fasteners; do work better with a lubricant of some sort, some don't need and some demand it. On cast iron blocks, they always say to put a drop of oil in but now many engine builders are using a thread locker or an anti-seize compound which would act as a lubricant. As I remember, SS fasteners do require a lube or some sort (the type may change on use though. It’s been too long since I was in to the process spec books) especially when using them against certain materials.

Some fasteners are self lubed (coated with a lube of some sort often mistaken for a protective surface. There are process specifications for each bolt (somewhere) including installation procedures but all too often we never get to see them and so we miss out on doing things correctly. You ask someone who works in a fastener store deep questions like this and all too often their eyes roll back into their heads and they drift off to sleep. Aircraft work was mentioned and there is one place that for sure does have the process specs for proper installation of all types of fasteners.

Some fasteners are self lubed (coated with a lube of some sort often mistaken for a protective surface. There are process specifications for each bolt (somewhere) including installation procedures but all too often we never get to see them and so we miss out on doing things correctly. You ask someone who works in a fastener store deep questions like this and all too often their eyes roll back into their heads and they drift off to sleep. Aircraft work was mentioned and there is one place that for sure does have the process specs for proper installation of all types of fasteners.

Lee

My opinion is worth slightly less than what you paid for it.

My opinion is worth slightly less than what you paid for it.

- raygreenwood

- Posts: 11907

- Joined: Wed Jan 22, 2003 12:01 am

Spot on. SS fasteners always require an antisieze. They are a soft (but togh) metal. They are susceptable to galling.

By the way...anti-sieze only works a a lubricant in a limityed fashion (when used properly). It does not mimic an oil or grease.

Oil and grease are designed to reduce friction. In doing that...the threads "skate" or hydroplane. They trick the torque wrench. Without proper friction, you end up with torque much higher than the wrench is actually telling you.

Anti-sieze is all about the metal additives. The oil isusually useless. The very best way to use anti-zieze is to brush it on thin and wipe it off....to get rid of the oils. This leaves only a "coloring" of microscopic metals on the surface. These simply grind up and plate themselves to the two thread surfaces preventing galling.

But yes.....whether or not you need an anti-sieze...is all about the combined metallurgy of the fastener system. Ray

By the way...anti-sieze only works a a lubricant in a limityed fashion (when used properly). It does not mimic an oil or grease.

Oil and grease are designed to reduce friction. In doing that...the threads "skate" or hydroplane. They trick the torque wrench. Without proper friction, you end up with torque much higher than the wrench is actually telling you.

Anti-sieze is all about the metal additives. The oil isusually useless. The very best way to use anti-zieze is to brush it on thin and wipe it off....to get rid of the oils. This leaves only a "coloring" of microscopic metals on the surface. These simply grind up and plate themselves to the two thread surfaces preventing galling.

But yes.....whether or not you need an anti-sieze...is all about the combined metallurgy of the fastener system. Ray

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

-

matberry

- Posts: 81

- Joined: Mon Feb 09, 2009 1:48 pm

Re: The Side Effects of Anti-Seize and Torque

Dredging an old post here but I thought this info is very relevant for our little aircooled engines that use such low torque settings for heads and such.

Years ago I was invited to an instructional meeting by a leading manufacturer of gaskets in Australia. They had a jig with a strain gauge measuring the actual clamp force or pressure applied to the gasket while the head bolts were torqued.

Dry threads torqued to 78 ft/lb, the gauge showed 1.7 ton of pressure, lube the threads and the pressure increased to around 4 tons, lube the thread and under the head of the bolt and the gauge went to over 7 tons of clamp pressure.

I always prepare the threads by cleaning and chasing with a tap, then lube with the apropriate stuff, but that info night really brought it home how important this often overlooked job is.

Years ago I was invited to an instructional meeting by a leading manufacturer of gaskets in Australia. They had a jig with a strain gauge measuring the actual clamp force or pressure applied to the gasket while the head bolts were torqued.

Dry threads torqued to 78 ft/lb, the gauge showed 1.7 ton of pressure, lube the threads and the pressure increased to around 4 tons, lube the thread and under the head of the bolt and the gauge went to over 7 tons of clamp pressure.

I always prepare the threads by cleaning and chasing with a tap, then lube with the apropriate stuff, but that info night really brought it home how important this often overlooked job is.

- Dale M.

- Posts: 1673

- Joined: Mon Oct 05, 2009 8:09 am

Re: The Side Effects of Anti-Seize and Torque

Works really good on some of those home plumbing jobs too where you don't want corrosion in the threads of screws and couplings or whatever you may want to take apart sometime later.....

Dale

Dale

"Fear The Government That Wants To Take Your Guns" - Thomas Jefferson

1970 "Kellison Sand Piper Roadster"

1970 "Kellison Sand Piper Roadster"

-

hpw

- Posts: 111

- Joined: Fri Aug 11, 2006 2:12 pm

Re: The Side Effects of Anti-Seize and Torque

Interesting info. So if your using anti-seize how do you adjust for torque settings? Is there a "rule of thumb" for doing so?matberry wrote:Dredging an old post here but I thought this info is very relevant for our little aircooled engines that use such low torque settings for heads and such.

Years ago I was invited to an instructional meeting by a leading manufacturer of gaskets in Australia. They had a jig with a strain gauge measuring the actual clamp force or pressure applied to the gasket while the head bolts were torqued.

Dry threads torqued to 78 ft/lb, the gauge showed 1.7 ton of pressure, lube the threads and the pressure increased to around 4 tons, lube the thread and under the head of the bolt and the gauge went to over 7 tons of clamp pressure.

I always prepare the threads by cleaning and chasing with a tap, then lube with the apropriate stuff, but that info night really brought it home how important this often overlooked job is.

I really need to know this as I have used it on all my suspension parts (66 ghia)

- david58

- Moderator

- Posts: 14101

- Joined: Sun Oct 23, 2005 6:14 pm

Re: The Side Effects of Anti-Seize and Torque

If you don't properly clean the threads and lubricate them who knows what the actual torque will be. By not cleaning the threads and lubricating them the torque will be effected by the friction and galling giving you false readings.hpw wrote: Interesting info. So if your using anti-seize how do you adjust for torque settings? Is there a "rule of thumb" for doing so?

I really need to know this as I have used it on all my suspension parts (66 ghia)

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.