Amr500 on 1641cc ! dyno p23

-

Alexios

- Posts: 98

- Joined: Sun Jun 09, 2013 11:36 am

Re: Gonna go amr500 on my car!

Hi Ruben

A bov (blow off valve) is most often used to vent boost pressure in a blow through setup. When the turbo/supercharger is before the throttle plate, you need a to vent the pressure when the throttle is closed.

A resirculation valve is what is most often used in supercharger setups to bypass the supercharger and minimize parasitic loses. It is pretty much simular to a bov and connects the intake and output of the supercharger. When the manifold is in vacuum, the valve is open and the supercharger is sort of bypassed/neutralized. When you approach manifold pressure close to 100kpa, the valve closes and you start building boost. If you see in my thread, i am using a resirc valve. It basically improves drivability and allows for a smoother transition between no boost and boost. I am planning to try to run without the resirc valve and see how drivability will be affected.

A pressure relief valve vents excessive boost from the manifold to prevent damage. It is only needed in a draw through setup when using a carb. The basic idea is that if you for some reason get a backfire, the fuel mixture in the manifold can ignite and create big pressure. This pressure can stop the supercharger dead on it tracks, the belt will most likely slip, you might blow of a silicon hose connection or even worse rupture the manifold and destroy the supercharger. I am not curtently running one of this since i run fuel injection( no fuel vapor in the manifold that can ignite in case of backfire) what is most commonly used in high boost supercharger setups in drag racing is a burst panel. Does the samme job as a pressure relief valve

Of the above, you "need" none in order to run the amr with a draw through carb but you should have a pressure relief valve/burst panel for safety.

In a draw through supercharger setup, the only way to change the amount of boost you are getting is by changing the drive ratio of the charger. A bov, resirc valve or pressure relief valve cannot be used in this setup to control/limit boost.

The amr 500 run at the max gear ratio on a 1600 will not produce more than a little bit over 1bar boost(max 17-18psi). A pressure relief valve that is at around 25 psi should work well. I am planning on adding one over the winter when i change my setup. Most likely i will get a 25psi one from the ebay link i posted earlier.

Concerning the sensor, i assume you are talking of the intake air temperature sensor(iat), i would get one with a 1/8npt lead and tap one of the end castings.

A boost gauge that goes up to 20 psi will work, get a 30 psi one if you are optimistic:). A gauge with lower psi rating will provide better resolution.

Alex

Sent from my iPhone using Tapatalk

A bov (blow off valve) is most often used to vent boost pressure in a blow through setup. When the turbo/supercharger is before the throttle plate, you need a to vent the pressure when the throttle is closed.

A resirculation valve is what is most often used in supercharger setups to bypass the supercharger and minimize parasitic loses. It is pretty much simular to a bov and connects the intake and output of the supercharger. When the manifold is in vacuum, the valve is open and the supercharger is sort of bypassed/neutralized. When you approach manifold pressure close to 100kpa, the valve closes and you start building boost. If you see in my thread, i am using a resirc valve. It basically improves drivability and allows for a smoother transition between no boost and boost. I am planning to try to run without the resirc valve and see how drivability will be affected.

A pressure relief valve vents excessive boost from the manifold to prevent damage. It is only needed in a draw through setup when using a carb. The basic idea is that if you for some reason get a backfire, the fuel mixture in the manifold can ignite and create big pressure. This pressure can stop the supercharger dead on it tracks, the belt will most likely slip, you might blow of a silicon hose connection or even worse rupture the manifold and destroy the supercharger. I am not curtently running one of this since i run fuel injection( no fuel vapor in the manifold that can ignite in case of backfire) what is most commonly used in high boost supercharger setups in drag racing is a burst panel. Does the samme job as a pressure relief valve

Of the above, you "need" none in order to run the amr with a draw through carb but you should have a pressure relief valve/burst panel for safety.

In a draw through supercharger setup, the only way to change the amount of boost you are getting is by changing the drive ratio of the charger. A bov, resirc valve or pressure relief valve cannot be used in this setup to control/limit boost.

The amr 500 run at the max gear ratio on a 1600 will not produce more than a little bit over 1bar boost(max 17-18psi). A pressure relief valve that is at around 25 psi should work well. I am planning on adding one over the winter when i change my setup. Most likely i will get a 25psi one from the ebay link i posted earlier.

Concerning the sensor, i assume you are talking of the intake air temperature sensor(iat), i would get one with a 1/8npt lead and tap one of the end castings.

A boost gauge that goes up to 20 psi will work, get a 30 psi one if you are optimistic:). A gauge with lower psi rating will provide better resolution.

Alex

Sent from my iPhone using Tapatalk

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Gonna go amr500 on my car!

introducing the power-tower!

that was a dry fit of the freshly welded stuff,

today I made the baseplate of the blower to match the base of the original fuel)pump mount.

had to take of a bit to get it lined out nicely, but still the blower is 2-3mm far backwards.

so will have to fit a washer behind the pulley on the blower.

wondering if it is regular thread? meaning turning the wrench left to get the bolt off?

that was a dry fit of the freshly welded stuff,

today I made the baseplate of the blower to match the base of the original fuel)pump mount.

had to take of a bit to get it lined out nicely, but still the blower is 2-3mm far backwards.

so will have to fit a washer behind the pulley on the blower.

wondering if it is regular thread? meaning turning the wrench left to get the bolt off?

Better to be blown than to suck!

-

Alexios

- Posts: 98

- Joined: Sun Jun 09, 2013 11:36 am

Re: Going amr500 on my car! Tha power-tower

The threads on the amr pulley are regular. Use a strap like the onrs you use to change an oil filter to hold the pulley still while you take the nut off. Do not try to hold the pulley still by jamming something into the rotors, it will damage the supercharger. The pulley is keyed and a washer will not slide over the key. You might need to do some filing on the washer. Why don't you enlarge the holes on the base plate and move the whole think forward by a few mm? The silicon hoses will still work if the tubes are a couple of mm out of alignment.

Looking good:)

Alex

Sent from my iPhone using Tapatalk

Looking good:)

Alex

Sent from my iPhone using Tapatalk

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

My friend has a tool like that. Will definatly try that!

I cant make the mouning holes bigger to move the mount forward cause the front mouning hole is already against the front of the vertical mounting plate.

I cant make the mouning holes bigger to move the mount forward cause the front mouning hole is already against the front of the vertical mounting plate.

Better to be blown than to suck!

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

Gave it a second look and used a narrower bolt to get the fuel pump base mount more to the back so the pulley lines out much better. Still have 1mm extra to play with. So happy with that.

Tommorow i will let my dad flatten an iron rod to connect the left side of the blower with the left exhaust bolt.

This will result in a verry strong total mounting position.

Also got the old throttle cable out and fitted a universal cable wich is much longer.

Used a outer bycicle cable to guide it from the fan shroud to the base plate of the carburetor. Works pretty well.

Worked out a way to connect the cable to the ball joint. Hope to drop it of at the welder tommorow.

Pics will follow soon.

Ruben

Tommorow i will let my dad flatten an iron rod to connect the left side of the blower with the left exhaust bolt.

This will result in a verry strong total mounting position.

Also got the old throttle cable out and fitted a universal cable wich is much longer.

Used a outer bycicle cable to guide it from the fan shroud to the base plate of the carburetor. Works pretty well.

Worked out a way to connect the cable to the ball joint. Hope to drop it of at the welder tommorow.

Pics will follow soon.

Ruben

Better to be blown than to suck!

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

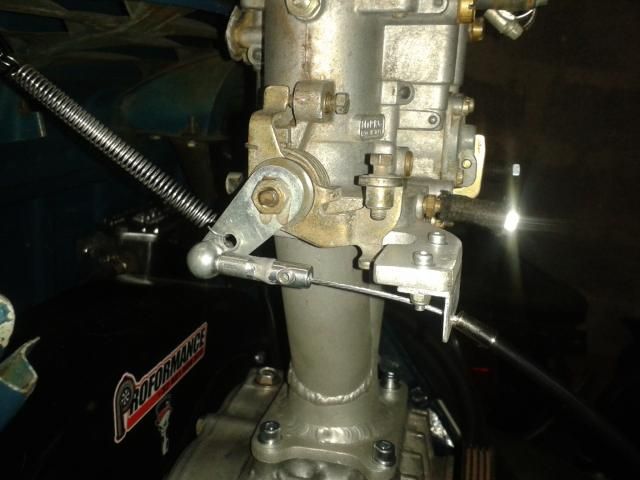

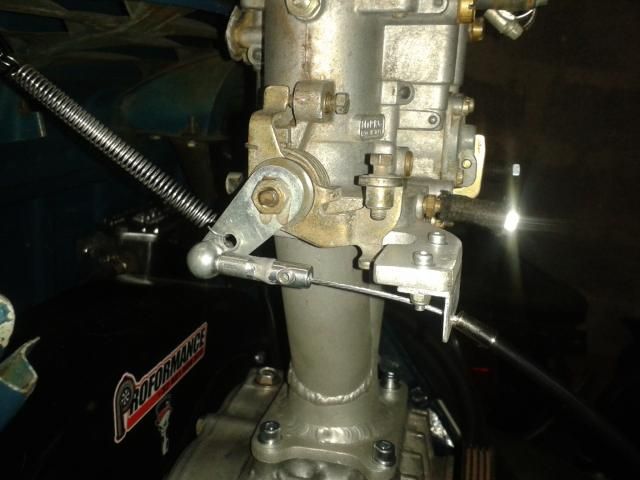

the finished throttle cable mount, works even smoother than my dual carb setup:

kinda hard to see but here we have the very tight nut on the mount:

overall photo:

got the round bar with 1 flattened side back from my dad. (to connect the amr with the exhaust bolt)

need to cut it to length and then give it back to make the other side flattened.

also test-fitted the steel hose clamps and checked if my coil still fits, yes it does, no pictures...

ordered an belt to, will have it tomorrow

will get together with my engine builder to discuss what sensors and gauges.

definatly the boost gauge and an A/F, maybe an inlet temp sensor...

greets,

feel free to comment or advise.

kinda hard to see but here we have the very tight nut on the mount:

overall photo:

got the round bar with 1 flattened side back from my dad. (to connect the amr with the exhaust bolt)

need to cut it to length and then give it back to make the other side flattened.

also test-fitted the steel hose clamps and checked if my coil still fits, yes it does, no pictures...

ordered an belt to, will have it tomorrow

will get together with my engine builder to discuss what sensors and gauges.

definatly the boost gauge and an A/F, maybe an inlet temp sensor...

greets,

feel free to comment or advise.

Better to be blown than to suck!

-

Alexios

- Posts: 98

- Joined: Sun Jun 09, 2013 11:36 am

Re: Going amr500 on my car! Tha power-tower

Hey Ruben. Looks good. The only potential issue i see is the silicon coupling under the blower. I am guessing you will have issues with it collapsing when the engine is running in vaccuum.

Alex

Sent from my iPhone using Tapatalk

Alex

Sent from my iPhone using Tapatalk

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

Got the belt mounted, clockwise from the top, amr -generator - idler - crank and back to the top.

Seems to work good but will need the re-enforcing rod cause there is some play in my mount when i wiggle it arround. 2 mounting bolts is not enough in my kind of mount.

Started with the carb intake too, all went well and its gonna be awesome if i pull it off!

But then the little daughter got sick and had to go get her at the daycare since the wife was still working....

Seems to work good but will need the re-enforcing rod cause there is some play in my mount when i wiggle it arround. 2 mounting bolts is not enough in my kind of mount.

Started with the carb intake too, all went well and its gonna be awesome if i pull it off!

But then the little daughter got sick and had to go get her at the daycare since the wife was still working....

Better to be blown than to suck!

-

Alexios

- Posts: 98

- Joined: Sun Jun 09, 2013 11:36 am

Re: Going amr500 on my car! Tha power-tower

You could tie the blower to the alternator strap in addition to one of the exhaust studs.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

did not have much time to work on the car today but did manage to make the inlet for the carb. about 80% finished.

CLOSED:

OPEN:

and the connecting rod between AMR and exhaust stud:

As you can see, also the fitted belt, your first reaction will be that there is not enough tension from crank to amr...

I know, but it was the longest 4 rib belt I could easily get a hold of here.

When I get the amr custom pulley made I will make it go: crank up to amr, down to tensioner, back up to dynamo and then back down to the crank.

Oh yes, alexios, i will also make a rod to connect the amr to the dynamo-strap. (thx for the tip)

And I bought a rusted out deck lid from a 58 bug for like 25$.

don't want to cut my original lid....

CLOSED:

OPEN:

and the connecting rod between AMR and exhaust stud:

As you can see, also the fitted belt, your first reaction will be that there is not enough tension from crank to amr...

I know, but it was the longest 4 rib belt I could easily get a hold of here.

When I get the amr custom pulley made I will make it go: crank up to amr, down to tensioner, back up to dynamo and then back down to the crank.

Oh yes, alexios, i will also make a rod to connect the amr to the dynamo-strap. (thx for the tip)

And I bought a rusted out deck lid from a 58 bug for like 25$.

don't want to cut my original lid....

Better to be blown than to suck!

- panel

- Posts: 4230

- Joined: Sun Sep 24, 2000 12:01 am

Re: Going amr500 on my car! Tha power-tower

Love it

'65 Bus with a JDM Subaru EJ20 Turbo

Built by Germans powered by Japanese and brought together by Canadians

Built by Germans powered by Japanese and brought together by Canadians

-

Alexios

- Posts: 98

- Joined: Sun Jun 09, 2013 11:36 am

Re: Going amr500 on my car! Tha power-tower

Make sure you always have with you the original alternator belt. In case of slip the long belt can fail leaving you stranded. In that case just pop the org belt back on and drive home:). The engine can draw air/fuel with the blower not spinning.

Alex

Sent from my iPhone using Tapatalk

Alex

Sent from my iPhone using Tapatalk

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

Yeah, i always carry a spare.

Can fuel mixture pass trough the amr when its not spinning? Looking at it, doesnt look like it.

Can fuel mixture pass trough the amr when its not spinning? Looking at it, doesnt look like it.

Better to be blown than to suck!

- rubenski

- Posts: 2038

- Joined: Mon Jun 30, 2014 3:28 am

Re: Going amr500 on my car! Tha power-tower

Hi,

In the final stage of fabrication. But the stage that goes slow and lots of little things.

Been looking for some boost and air fuel ratio gauges and sensor sets.

This came up, any experience somebody??

http://www.aemelectronics.com/?q=produc ... safe-gauge

In the final stage of fabrication. But the stage that goes slow and lots of little things.

Been looking for some boost and air fuel ratio gauges and sensor sets.

This came up, any experience somebody??

http://www.aemelectronics.com/?q=produc ... safe-gauge

Better to be blown than to suck!

-

Clonebug

- Posts: 4745

- Joined: Thu Feb 15, 2007 9:28 pm

Re: Going amr500 on my car! Tha power-tower

That's an expensive wideband.......

I am using a PLX and I am quite happy with it for $200.00

This is the Gen 4

http://www.plxdevices.com/product_info. ... MAFR_DM6G4

This is the Gen 3 which I have...

http://www.plxdevices.com/product_info. ... MAFR_DM6G3

The plug in connectors are just standard mini Molex and can be bought for $7.00 on Ebay. You can always make your own cable extension if the original isn't long enough.

I am using a PLX and I am quite happy with it for $200.00

This is the Gen 4

http://www.plxdevices.com/product_info. ... MAFR_DM6G4

This is the Gen 3 which I have...

http://www.plxdevices.com/product_info. ... MAFR_DM6G3

The plug in connectors are just standard mini Molex and can be bought for $7.00 on Ebay. You can always make your own cable extension if the original isn't long enough.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.