Downunder turbo oval & Datsun 510 adventures

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Hmmm, nasty. I'll look more into POR15 before I use it, but I'm not planning on using E85 at this stage.Fiatdude wrote:Here's what an alcohol resistant coating looked like in my prefilter in my Oval (it's down to >20% flow at this point) most of it was a very very fine powdery substance that you can barely see in the crevasses -- P.S. all the injectors were also clogged by this time too

http://i586.photobucket.com/albums/ss30 ... 143486.jpg

- Piledriver

- Moderator

- Posts: 22775

- Joined: Sat Feb 16, 2002 12:01 am

Re: NEW plan - 1600 TURBO + oval + downunder

Fiatdude wrote:Here's what an alcohol resistant coating looked like in my prefilter in my Oval (it's down to >20% flow at this point) most of it was a very very fine powdery substance that you can barely see in the crevasses -- P.S. all the injectors were also clogged by this time too

http://i586.photobucket.com/albums/ss30 ... 143486.jpg

Exactly which coatings were you using?

They are not all the same.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Interesting... just found this stuff. Reckon I might give it a go!

http://www.caswellplating.com.au/store/ ... ank-sealer

http://www.caswellplating.com.au/store/ ... ank-sealer

- Fiatdude

- Posts: 971

- Joined: Mon Oct 12, 2009 6:58 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Hirsch alcohol and POR

POR first and within a week tank was rusting again -- then the Hirsch which came HIGHLY recommended

http://www.hirschauto.com/Gas-Tank-Seal ... roducts/4/

-- the pictures are of what the Hirsch did -- Threw away the tank right after this and went with a fuel cell

POR first and within a week tank was rusting again -- then the Hirsch which came HIGHLY recommended

http://www.hirschauto.com/Gas-Tank-Seal ... roducts/4/

-- the pictures are of what the Hirsch did -- Threw away the tank right after this and went with a fuel cell

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

I've been building a bass guitar... finally got it finished.

Here's the build thread in case you're interested...

http://www.talkbass.com/threads/build-1 ... 2.1113666/

So with that all done, I can finally get into the beetle. I pulled the trans and all was not happy. The oil smelled so bad we thought there was a gas leak in the house. I was planning to the use the axles, but maybe not...

Driver's side sadness.

Passenger's side wrongness.

Then there was all the well oiled brakes. Course the whole trans was leaking EVERYWHERE. On the upside, the chassis is NEVER going to rust from the inside out.

My friend Emil has been going at it re-wiring the car too. He's an auto-electrician by trade and a machine. He very kindly offered to rewire the car for me.

Which is just as well, because by his estimations the car was about to short out and burn down.

I've had heaps of part turn up recently too, which is nice. The CB header I got is better than anything I could have built.

Late this afternoon I got back in the shed and hit a few things. The plan has always been to have nothingon the car that wasn't reversible, but then I thought I need to do something help it with such a big power upgrade. So I seam-welded the horns...

I guess if a future owner is not happy, he could grind them all back flat, but in the meantime the horns won't flex as much. Course I need to do some other triangulating in the back end. Still thinking about how I can do that effectively with oil coolers and the like under the back end of the car.

In the process of welding and grinding, my 11yo daughter was helping me and had her first go at welding.

Happy chicken.

Here's the build thread in case you're interested...

http://www.talkbass.com/threads/build-1 ... 2.1113666/

So with that all done, I can finally get into the beetle. I pulled the trans and all was not happy. The oil smelled so bad we thought there was a gas leak in the house. I was planning to the use the axles, but maybe not...

Driver's side sadness.

Passenger's side wrongness.

Then there was all the well oiled brakes. Course the whole trans was leaking EVERYWHERE. On the upside, the chassis is NEVER going to rust from the inside out.

My friend Emil has been going at it re-wiring the car too. He's an auto-electrician by trade and a machine. He very kindly offered to rewire the car for me.

Which is just as well, because by his estimations the car was about to short out and burn down.

I've had heaps of part turn up recently too, which is nice. The CB header I got is better than anything I could have built.

Late this afternoon I got back in the shed and hit a few things. The plan has always been to have nothingon the car that wasn't reversible, but then I thought I need to do something help it with such a big power upgrade. So I seam-welded the horns...

I guess if a future owner is not happy, he could grind them all back flat, but in the meantime the horns won't flex as much. Course I need to do some other triangulating in the back end. Still thinking about how I can do that effectively with oil coolers and the like under the back end of the car.

In the process of welding and grinding, my 11yo daughter was helping me and had her first go at welding.

Happy chicken.

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Least favorite job so far = new sender fuel line. This has taken me hours and hours of thinking, stuffing around, pulling it out and putting back in again, but it's DONE! I would like to have run it through the cabin, but it's illegal on road cars in my state.

The original plan was to try and run it through the hole opposite to the original fuel line on the top of the right hand chassis tube. It just didn't work, so I cooked up the plan to run it like the accelerator and clutch tubes. This was still hard work but much better.

The other end of the chassis was similarly hard work with the body still on the car...

Over the top of the throttle linkage = WRONG. So try again.

In and under the linkage alongside the other fuel line but yet to come up through the hole under the tank...

In position. I still have a few cable ties and clamps to put on, but it all essentially ready to go. Big thanks to my wife and several mates who helped out a lot.

So the old fuel hose will the return and the new one will be the send.

The other thing going on at the mo is the car's new loom was fed through yesterday arvo. Should have seen how awful the old one was. Can you say "fire hazard"?

The original plan was to try and run it through the hole opposite to the original fuel line on the top of the right hand chassis tube. It just didn't work, so I cooked up the plan to run it like the accelerator and clutch tubes. This was still hard work but much better.

The other end of the chassis was similarly hard work with the body still on the car...

Over the top of the throttle linkage = WRONG. So try again.

In and under the linkage alongside the other fuel line but yet to come up through the hole under the tank...

In position. I still have a few cable ties and clamps to put on, but it all essentially ready to go. Big thanks to my wife and several mates who helped out a lot.

So the old fuel hose will the return and the new one will be the send.

The other thing going on at the mo is the car's new loom was fed through yesterday arvo. Should have seen how awful the old one was. Can you say "fire hazard"?

- Piledriver

- Moderator

- Posts: 22775

- Joined: Sat Feb 16, 2002 12:01 am

Re: NEW plan - 1600 TURBO + oval + downunder

petew wrote: The other thing going on at the mo is the car's new loom was fed through yesterday arvo. Should have seen how awful the old one was. Can you say "fire hazard"?

Pics as a warning to others?

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Ok, as Piledriver requested, here are some pics to show you why you should replace the loom in your old car...

First up here's a pic of the 1956 6 volt loom cut open...

To the naked eye, it all looks pretty clean and in good nic. In fact, just to look at it, it would be fine. In practice, it's far from it.

Here's two tail-light wires just a few inches down the loom from there near where they come out of the loom...

Both wires are melted together and to the outer sheath.

Further up the loom...

If you look in the center, you can see where there is a divot in the grey wire. It and the bright blue wire had been melted together.

2 inches further up the loom there is this...

The grey wire with the black stripe was melted solidly to the outer sheath.

The other thing to say about the loom was, the insulation and the outer sheath had become extremely hard and stiff. Cutting the outer sheath off the loom was tremendously hard work even with a carpet cutting knife. If the insulation is cracking, then it will arc inside the loom.

All the places where these wires are melted together demonstrate long term arcing in the circuits those wires supply. As the arcing increases the temperatures increase to the point where the insulation melts enough to let the strands of wire touch. Once that happens it's only a matter of time before there is a serious short and the car can very easily catch on fire. Only a recently, a friend of mine told me about a relative who's VW had burnt to the ground in their garage from this sort of electrical fire. They hadn't even seen it coming. You might say, "but that was only one wire in your loom causing all that trouble". The problem is... how do you know it's only one? And, how do you know which one it is? We couldn't tell until we pulled the loom out completely.

The thing is, the sort of arcing I'm talking about is typical for the style of bulb and fuse connectors that came in vintage VWs. The ceramic fuses and spring contacts all arc when the car is driving along vibrating. So even if your car has had a nice life (like mine has), odds are the loom is going to be similar to mine. If it's sat outside in the heat for long periods, had an accident, electrical fire or been messed about with, it's likely to be a LOT worse.

New looms are a few hundred dollars and not hard to fit. A new fuse box is similarly cheap and kits are available. We wouldn't think twice about dropping this sort of money on a stereo or an exhaust... why wouldn't we do the same to stop the whole car from catching on fire?

P.s. in other news, the new fuel line is all in and secured well.

First up here's a pic of the 1956 6 volt loom cut open...

To the naked eye, it all looks pretty clean and in good nic. In fact, just to look at it, it would be fine. In practice, it's far from it.

Here's two tail-light wires just a few inches down the loom from there near where they come out of the loom...

Both wires are melted together and to the outer sheath.

Further up the loom...

If you look in the center, you can see where there is a divot in the grey wire. It and the bright blue wire had been melted together.

2 inches further up the loom there is this...

The grey wire with the black stripe was melted solidly to the outer sheath.

The other thing to say about the loom was, the insulation and the outer sheath had become extremely hard and stiff. Cutting the outer sheath off the loom was tremendously hard work even with a carpet cutting knife. If the insulation is cracking, then it will arc inside the loom.

All the places where these wires are melted together demonstrate long term arcing in the circuits those wires supply. As the arcing increases the temperatures increase to the point where the insulation melts enough to let the strands of wire touch. Once that happens it's only a matter of time before there is a serious short and the car can very easily catch on fire. Only a recently, a friend of mine told me about a relative who's VW had burnt to the ground in their garage from this sort of electrical fire. They hadn't even seen it coming. You might say, "but that was only one wire in your loom causing all that trouble". The problem is... how do you know it's only one? And, how do you know which one it is? We couldn't tell until we pulled the loom out completely.

The thing is, the sort of arcing I'm talking about is typical for the style of bulb and fuse connectors that came in vintage VWs. The ceramic fuses and spring contacts all arc when the car is driving along vibrating. So even if your car has had a nice life (like mine has), odds are the loom is going to be similar to mine. If it's sat outside in the heat for long periods, had an accident, electrical fire or been messed about with, it's likely to be a LOT worse.

New looms are a few hundred dollars and not hard to fit. A new fuse box is similarly cheap and kits are available. We wouldn't think twice about dropping this sort of money on a stereo or an exhaust... why wouldn't we do the same to stop the whole car from catching on fire?

P.s. in other news, the new fuel line is all in and secured well.

- Piledriver

- Moderator

- Posts: 22775

- Joined: Sat Feb 16, 2002 12:01 am

Re: NEW plan - 1600 TURBO + oval + downunder

Frequently the black wire that run in the middle of that bundle is extra krispy... It is the ignition power/backup light supply.

It is also NOT fused from the factory on most ACVWs, unless someone fixed that for you.

(They did eventually fix that stupid, but it was ~70 or something)

Even later cars can have it unfused if some PO relocated it to the wrong side of the fusebox...

...possibly because they kept blowing the fuse.

It is also NOT fused from the factory on most ACVWs, unless someone fixed that for you.

(They did eventually fix that stupid, but it was ~70 or something)

Even later cars can have it unfused if some PO relocated it to the wrong side of the fusebox...

...possibly because they kept blowing the fuse.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Well, I've spent as much time walking round the car scratching my chin as working on it in the last few days. The big question in my mind is where to put all the fuel system. I went to the local parts shop today and pick up a filter and boy I'm happy I did now!

The pump I have (on the right) has a 1/2" inlet and the only filters I can get in that size are metal EFI (40 micron). I'm kinda surprised in a way, although it explains why I filled the last pump up with junk using just a plastic low pressure filter in front of it. I'm thinking that the pump was designed to have an EFI filter between it and the tank. With that and some hose in hand I pulled out some old coil mounts and started mocking things up...

This was one of my ideas...

My issue with this is, if the car sustains a front hit, the pump will probably get a hit too and all hell will break loose. My next door neighbor was burned badly and lost his fiance in such an accident in the early 1960s... in a beetle.

I'm also desperately trying NOT to drill holes anywhere in my very straight, original paint 56' body. The upshot of this has me thinking the best place to mount the filter and pump is on the underside of the tank. Thoughts?

Which brings me to the next thing. I'm seriously considering leaving the tank volume as is. As far as I can see, any mods will only net a few extra litres at best. The car is not set up for the freeway and it's not my daily, so I'm thinking all that work might be a waste of time. I'll just weld in a new bottom with a proper fuel collection bowl and be done with it. Again, happy to hear people's thoughts on this...

The pump I have (on the right) has a 1/2" inlet and the only filters I can get in that size are metal EFI (40 micron). I'm kinda surprised in a way, although it explains why I filled the last pump up with junk using just a plastic low pressure filter in front of it. I'm thinking that the pump was designed to have an EFI filter between it and the tank. With that and some hose in hand I pulled out some old coil mounts and started mocking things up...

This was one of my ideas...

My issue with this is, if the car sustains a front hit, the pump will probably get a hit too and all hell will break loose. My next door neighbor was burned badly and lost his fiance in such an accident in the early 1960s... in a beetle.

I'm also desperately trying NOT to drill holes anywhere in my very straight, original paint 56' body. The upshot of this has me thinking the best place to mount the filter and pump is on the underside of the tank. Thoughts?

Which brings me to the next thing. I'm seriously considering leaving the tank volume as is. As far as I can see, any mods will only net a few extra litres at best. The car is not set up for the freeway and it's not my daily, so I'm thinking all that work might be a waste of time. I'll just weld in a new bottom with a proper fuel collection bowl and be done with it. Again, happy to hear people's thoughts on this...

-

Clonebug

- Posts: 4745

- Joined: Thu Feb 15, 2007 9:28 pm

Re: NEW plan - 1600 TURBO + oval + downunder

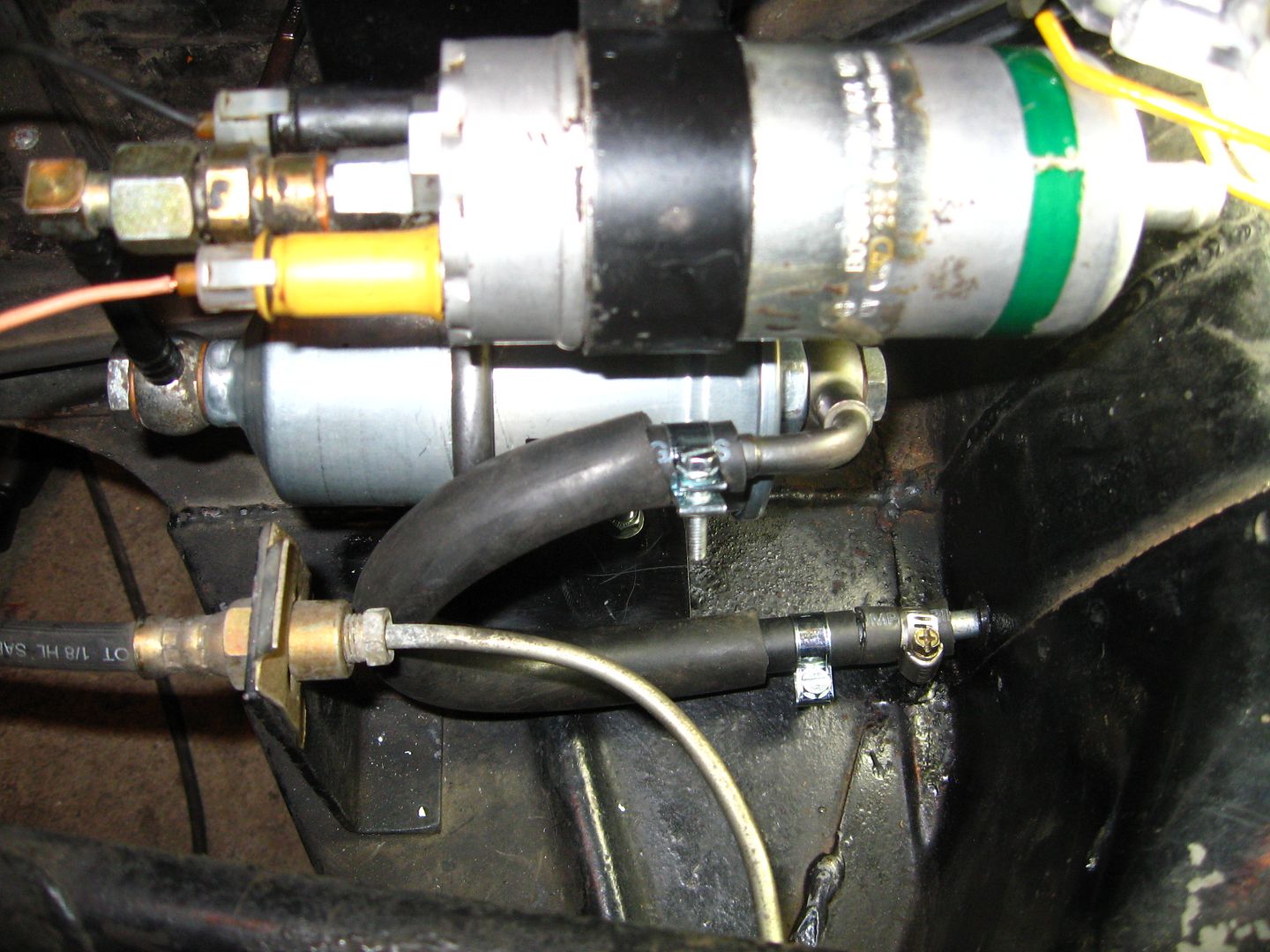

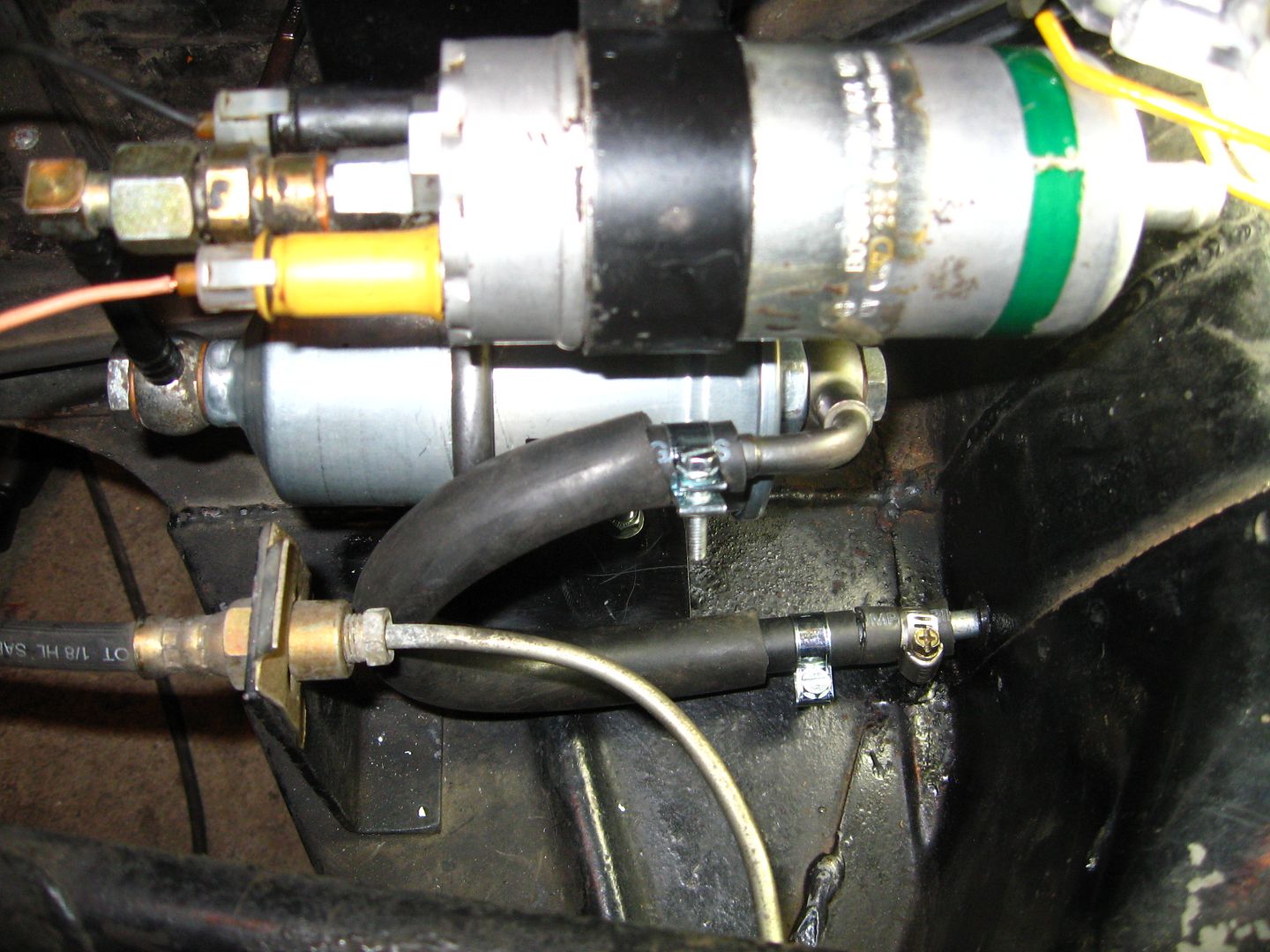

This is what I did on my fuel system.

It's on a buggy but it has the same pump with 1/2 inch inlet that I took off a 94 Volvo 940 Turbo.

I used a Golf pressure side fuel filter with banjo fittings and a cheap steel prefilter from NAPA that had 1/2 inch inlet and outlet.

I had to swap out the 1/2 inch inlet hose from tank to filter due to it not liking the 180 degree bend.

I found some really flexible hose that I'm going to use this winter that won't kink.

I just have to get the length figured out and go get it.

It's on the list of my winter upgrades.

It has been trouble free for 2 years now.

It's on a buggy but it has the same pump with 1/2 inch inlet that I took off a 94 Volvo 940 Turbo.

I used a Golf pressure side fuel filter with banjo fittings and a cheap steel prefilter from NAPA that had 1/2 inch inlet and outlet.

I had to swap out the 1/2 inch inlet hose from tank to filter due to it not liking the 180 degree bend.

I found some really flexible hose that I'm going to use this winter that won't kink.

I just have to get the length figured out and go get it.

It's on the list of my winter upgrades.

It has been trouble free for 2 years now.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Thanks for that clonebug.  The plan is to put another EFI filter down near the engine to strain any possible junk out of the hard line.

The plan is to put another EFI filter down near the engine to strain any possible junk out of the hard line.

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Thought about mounting using ultra HD hook and loop material? No holes needed...

- petew

- Posts: 3928

- Joined: Sat Oct 07, 2006 4:05 pm

Re: NEW plan - 1600 TURBO + oval + downunder

Hmmm, interesting...