Posted: Tue Apr 24, 2007 2:17 pm

These are verysimilar to the pulleys on water cooled rabbits and golfs.

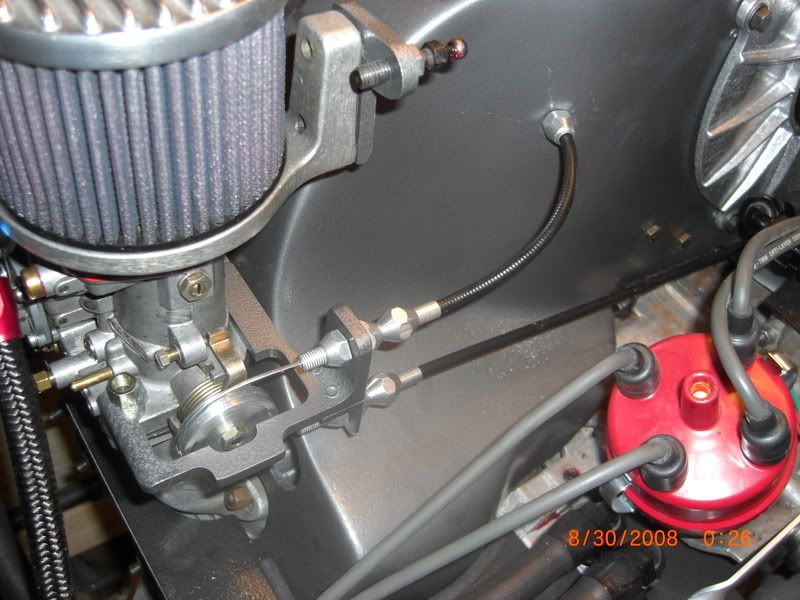

I have one I am playing with with my "bullet" style plateless TB that is a crude version of what I will describe below.

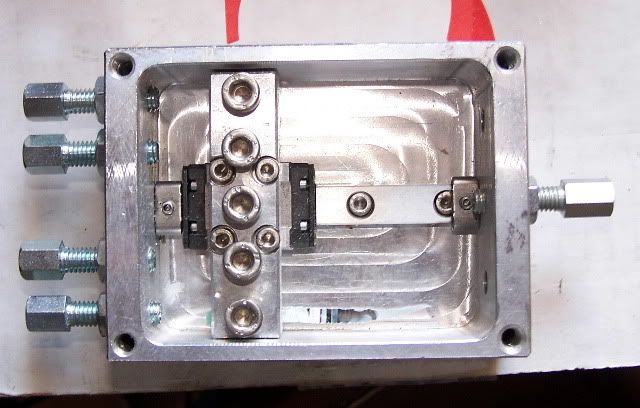

The thing to think about that I did not see mention of in this thread:......if you bore several different center shaft holes...eccentrically....off center....as well as several different cable mounting holes......it is quite easy to have a huge number of opening ratios...per mm of cable pull.

If you want to see the "parent" of this idea...simply look at "nautilus" excercise equipment. It is an eccentric "capstan". Turn diameter ratios can be adjusted by changing the relationship of the center bore and the mounting point for the chain/cable.....with reference to the length of the elliptical curve around the outside where the chain/cable runs.

Tougher to make....but maybe not.

The cable end could simply be a small heim joint... mounted to the disc on a steel pin with and E-clip. How far from the center this "pin" is mounted...governs the turn speed ratio.

Mounting the cable end closer to the center of the disc is quicker rotation speed......but shorter total stroke length in degrees of rotation.

Mounting the cable end closer to the outside edge is slower rotation speed but longer total stroke length in degrees of rotation.

You should also haveone dead center and several off-center mounting holes for the actual throttle shaft boss..........so.......

In operation ...you could have the cable intersect close to the center of the disc for that quick rotation speed.......but then mount the throttle shaft in one of the off center holes...opposite eccentrically to lengthen the stroke.....so you can get the best of both worlds. Totally adjustable.

The wire guide itself...instead of being a groove...can be a series of pegs with simple delrin roller chain bearings slipped over them.....to put in any holes you want to vary the diameter of the rotaion.

So to recap...you have a disc. (1) series of holes near the center ring for throttle shaft. One dead center..several eccentrically around in a spiral coming out from that. Maybe 5-6 choices. (

2) A series of holes for the cable heim joint mount pins. Some close to the outside edge of the disc....some toward the center....again descending from outside to the inside in a spiral arrangement. Maybe 10-12 choices total.

(3) several series of smaller holes...in complete circular rings...for the cable guide pins...maybe 4 rings of holes with ring diameter descending in diameter from the outside of the disc in.....maybe 1o pins on the outer...7 on the next......4 on the next...etc.

You could build this on a drill press. It would be incredibly adjustable.....and would solve many problems with improper TB sizing versus pedal stroke versus TPS stroke on plenum systems. Just some thoughts. Ray

I have one I am playing with with my "bullet" style plateless TB that is a crude version of what I will describe below.

The thing to think about that I did not see mention of in this thread:......if you bore several different center shaft holes...eccentrically....off center....as well as several different cable mounting holes......it is quite easy to have a huge number of opening ratios...per mm of cable pull.

If you want to see the "parent" of this idea...simply look at "nautilus" excercise equipment. It is an eccentric "capstan". Turn diameter ratios can be adjusted by changing the relationship of the center bore and the mounting point for the chain/cable.....with reference to the length of the elliptical curve around the outside where the chain/cable runs.

Tougher to make....but maybe not.

The cable end could simply be a small heim joint... mounted to the disc on a steel pin with and E-clip. How far from the center this "pin" is mounted...governs the turn speed ratio.

Mounting the cable end closer to the center of the disc is quicker rotation speed......but shorter total stroke length in degrees of rotation.

Mounting the cable end closer to the outside edge is slower rotation speed but longer total stroke length in degrees of rotation.

You should also haveone dead center and several off-center mounting holes for the actual throttle shaft boss..........so.......

In operation ...you could have the cable intersect close to the center of the disc for that quick rotation speed.......but then mount the throttle shaft in one of the off center holes...opposite eccentrically to lengthen the stroke.....so you can get the best of both worlds. Totally adjustable.

The wire guide itself...instead of being a groove...can be a series of pegs with simple delrin roller chain bearings slipped over them.....to put in any holes you want to vary the diameter of the rotaion.

So to recap...you have a disc. (1) series of holes near the center ring for throttle shaft. One dead center..several eccentrically around in a spiral coming out from that. Maybe 5-6 choices. (

2) A series of holes for the cable heim joint mount pins. Some close to the outside edge of the disc....some toward the center....again descending from outside to the inside in a spiral arrangement. Maybe 10-12 choices total.

(3) several series of smaller holes...in complete circular rings...for the cable guide pins...maybe 4 rings of holes with ring diameter descending in diameter from the outside of the disc in.....maybe 1o pins on the outer...7 on the next......4 on the next...etc.

You could build this on a drill press. It would be incredibly adjustable.....and would solve many problems with improper TB sizing versus pedal stroke versus TPS stroke on plenum systems. Just some thoughts. Ray