Cam choice for my 2.7l T4 engine

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

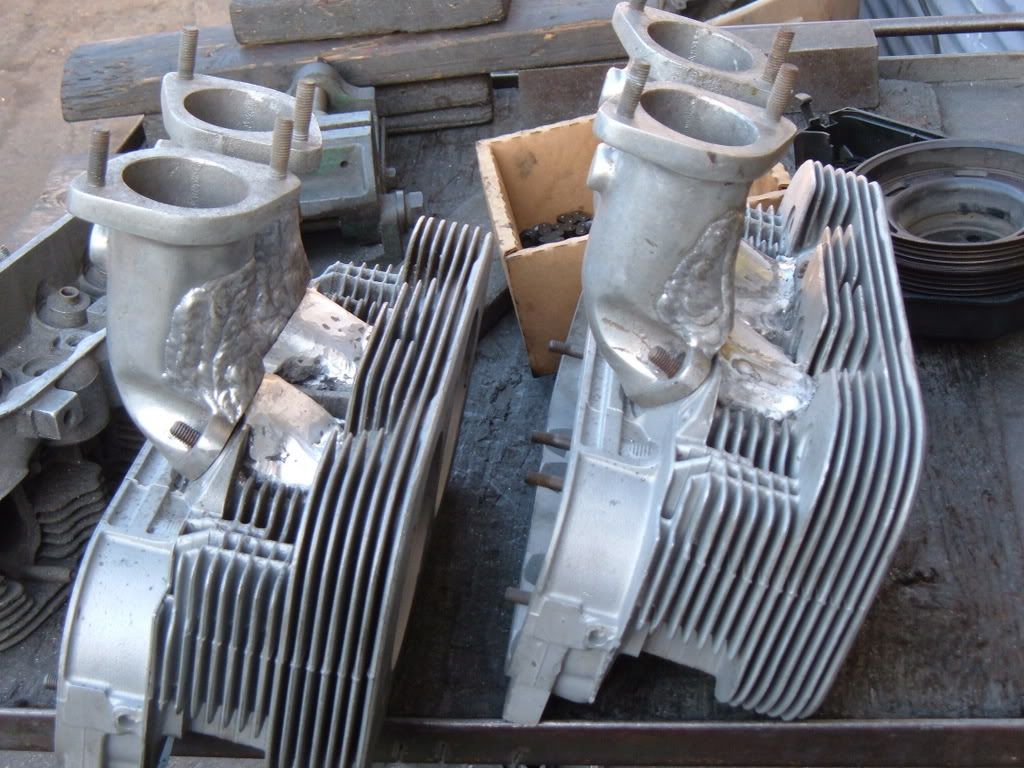

Welding the plug-holes...(Plugs will be placed like the on Porsche 914 heads).

Last edited by VW1300-NORWAY on Wed Dec 19, 2007 12:35 pm, edited 1 time in total.

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hello,

Looks really nice but I notice two things that would worry me.

Why not welding the critical top fin above the sparkplug hole. You will really need that if you run large diameter cylinders in order to support and not ask for immediate leakage.

Furthermore, seems you have the seats installed prior to welding?

Or will you replace the seats for bronze or in any case replace them?

I would be afraid of introducing potential lose seats.

My preffered method is to have anything welded done first, then lastly do the final machining and shrink in the seats.

In any case, nice engine you got going. Will be nice.

Cam? Get one of Jakes split duration.

Looks really nice but I notice two things that would worry me.

Why not welding the critical top fin above the sparkplug hole. You will really need that if you run large diameter cylinders in order to support and not ask for immediate leakage.

Furthermore, seems you have the seats installed prior to welding?

Or will you replace the seats for bronze or in any case replace them?

I would be afraid of introducing potential lose seats.

My preffered method is to have anything welded done first, then lastly do the final machining and shrink in the seats.

In any case, nice engine you got going. Will be nice.

Cam? Get one of Jakes split duration.

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

Hi, and thanks for your reply!Frallan wrote:Hello,

Looks really nice but I notice two things that would worry me.

Why not welding the critical top fin above the sparkplug hole. You will really need that if you run large diameter cylinders in order to support and not ask for immediate leakage.

Furthermore, seems you have the seats installed prior to welding?

Or will you replace the seats for bronze or in any case replace them?

I would be afraid of introducing potential lose seats.

My preffered method is to have anything welded done first, then lastly do the final machining and shrink in the seats.

In any case, nice engine you got going. Will be nice.

Cam? Get one of Jakes split duration.

I'll do some more welding on these heads...

And the seats will be replaced

Thanks,

Geir

- Type 4 Unleashed

- Moderator

- Posts: 2202

- Joined: Tue Nov 08, 2005 10:43 pm

Really happy to see this kind of stuff, reminds me of someone else.VW1300-NORWAY wrote:Some more welding

This is what I've done so far....hope to finish this engine before the summer season here in Norway...and make 200HP+ in the dyno

Geir

Richard

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

-

eugene

- Posts: 50

- Joined: Thu Jun 28, 2007 4:31 pm

Nice job. I'm also planing to do some welding on mine heads soon. Spark relocation and some combustion mods in order to promote squish and rise the compression. Do you know the angle of the spark plug on the 914 GB heads? (compared to the horizontal or vertical plane of the heads)

Which filler rod did you use for welding? Thanks.

Which filler rod did you use for welding? Thanks.

- Type 4 Unleashed

- Moderator

- Posts: 2202

- Joined: Tue Nov 08, 2005 10:43 pm

I will find out this stuff for you, but it won't be till after the 1st of the year.eugene wrote:Nice job. I'm also planing to do some welding on mine heads soon. Spark relocation and some combustion mods in order to promote squish and rise the compression. Do you know the angle of the spark plug on the 914 GB heads? (compared to the horizontal or vertical plane of the heads)

Which filler rod did you use for welding? Thanks.

Richard

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

-

VW1300-NORWAY

- Posts: 48

- Joined: Tue Oct 04, 2005 4:34 am

- Wally

- Posts: 4564

- Joined: Mon Oct 28, 2002 12:01 am

Try to have the crank nitrated. IIRC, the come back from DPR very soft...

Nice lifters! What do they weigh? and what are they made of? (tool steel perhaps, like Udo Becks T1 lifters?)

Nice lifters! What do they weigh? and what are they made of? (tool steel perhaps, like Udo Becks T1 lifters?)

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi in a streetlegal 1303

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks