Page 8 of 16

Posted: Fri Jan 04, 2008 11:48 pm

by Type 4 Unleashed

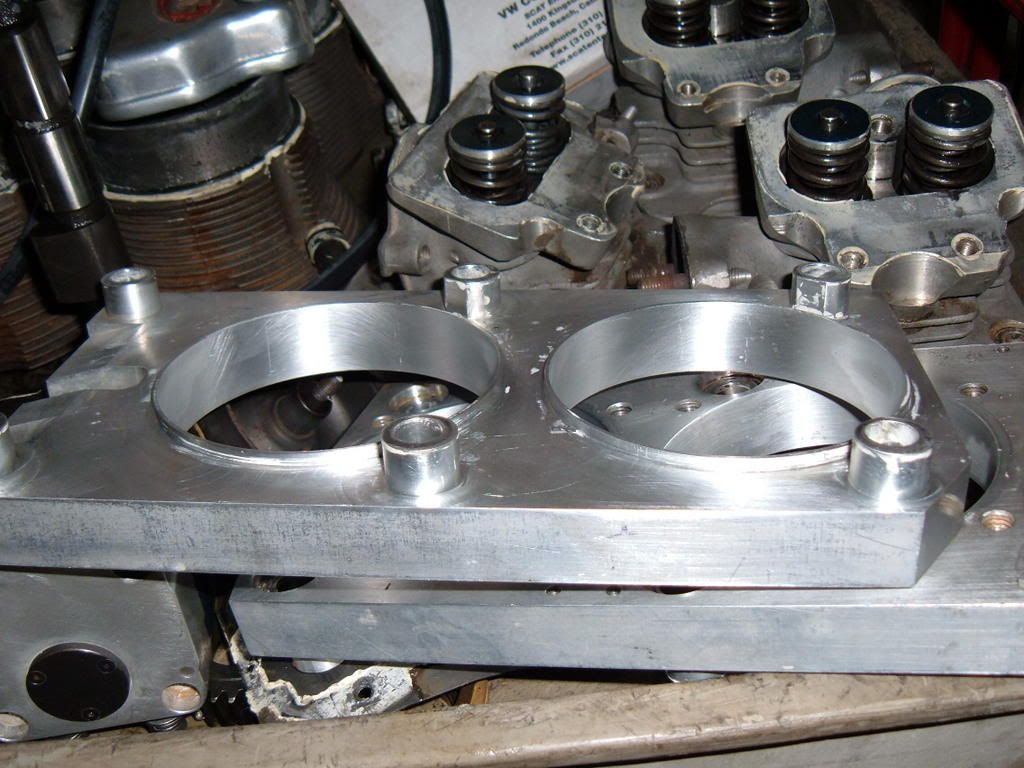

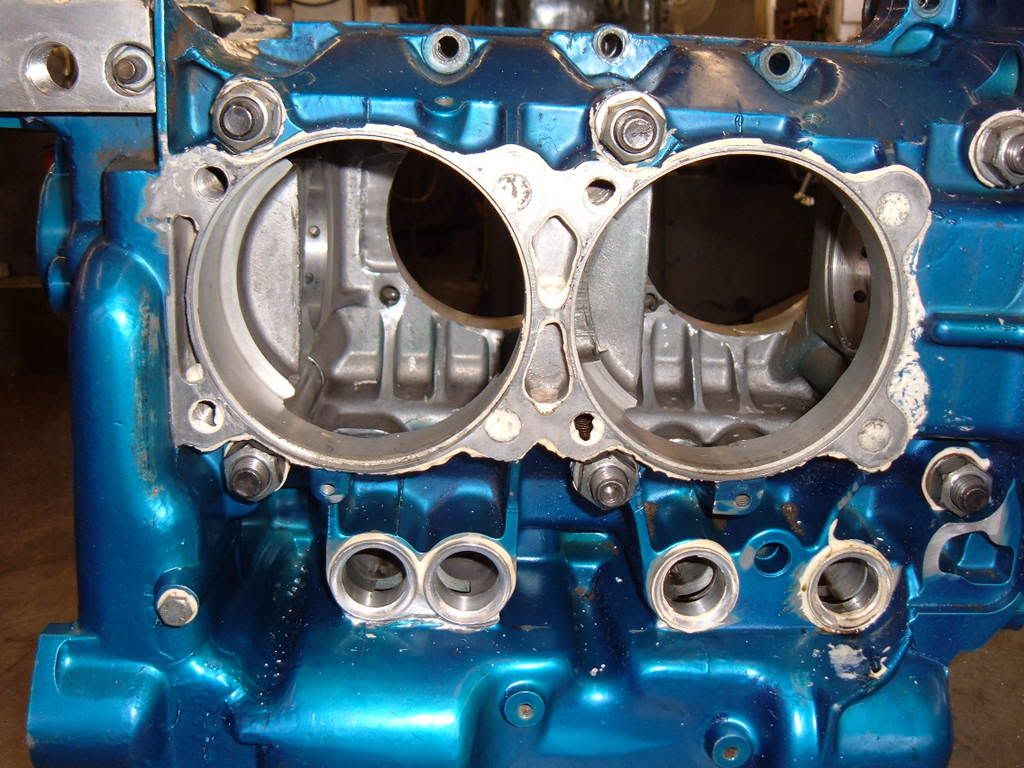

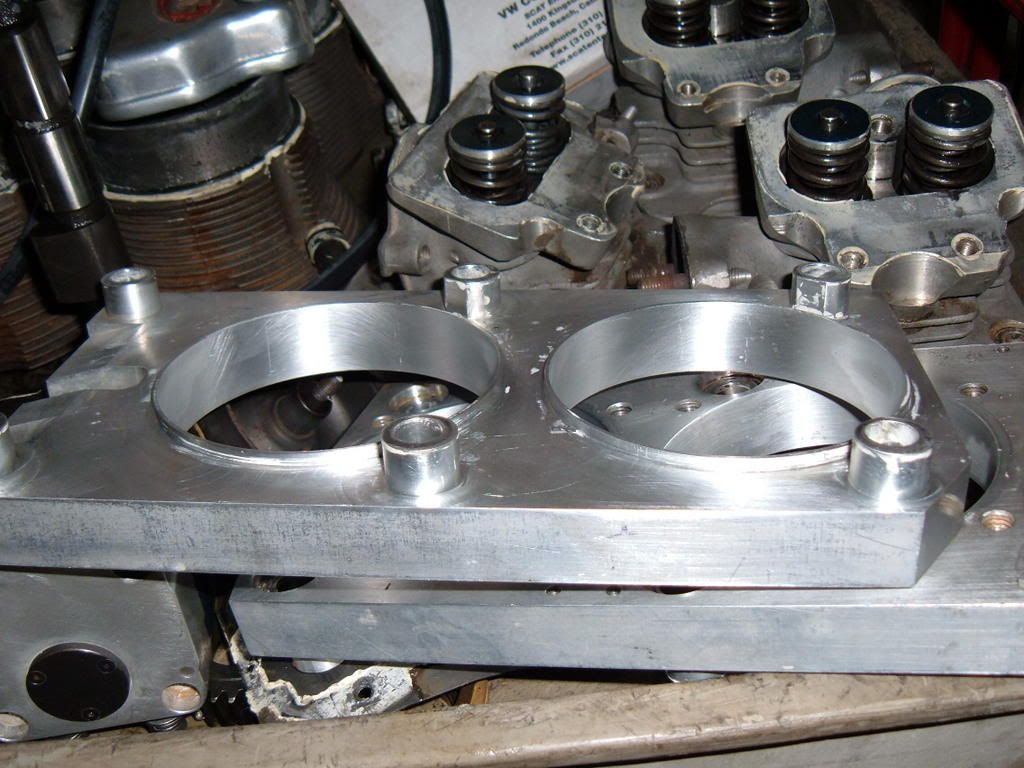

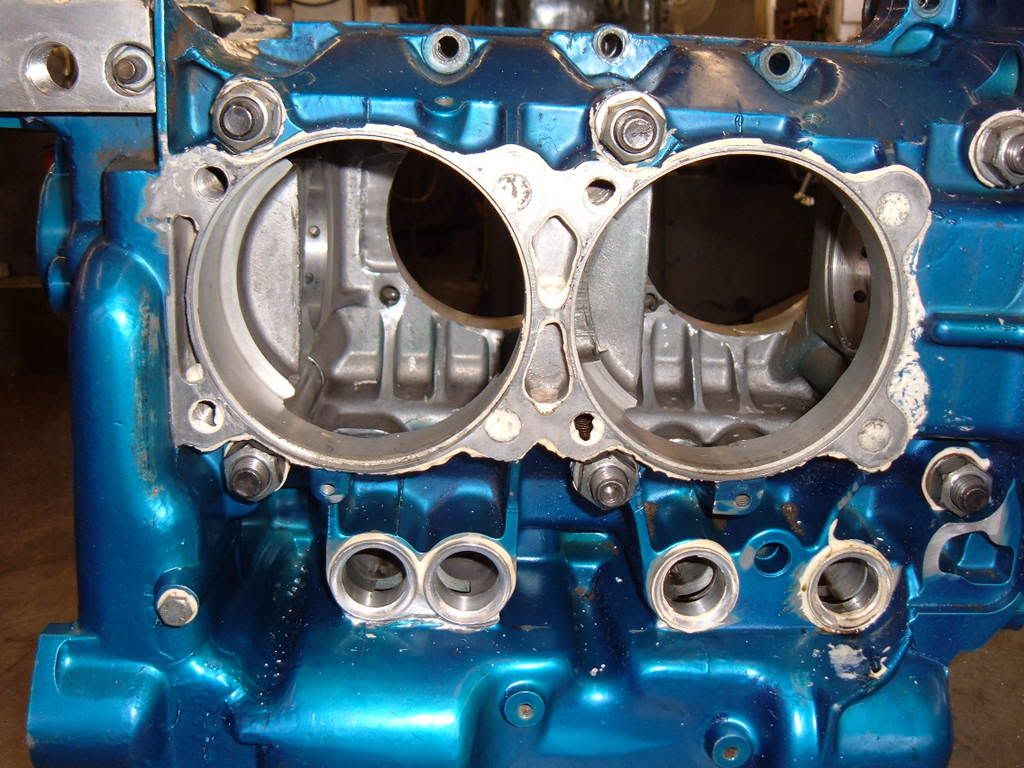

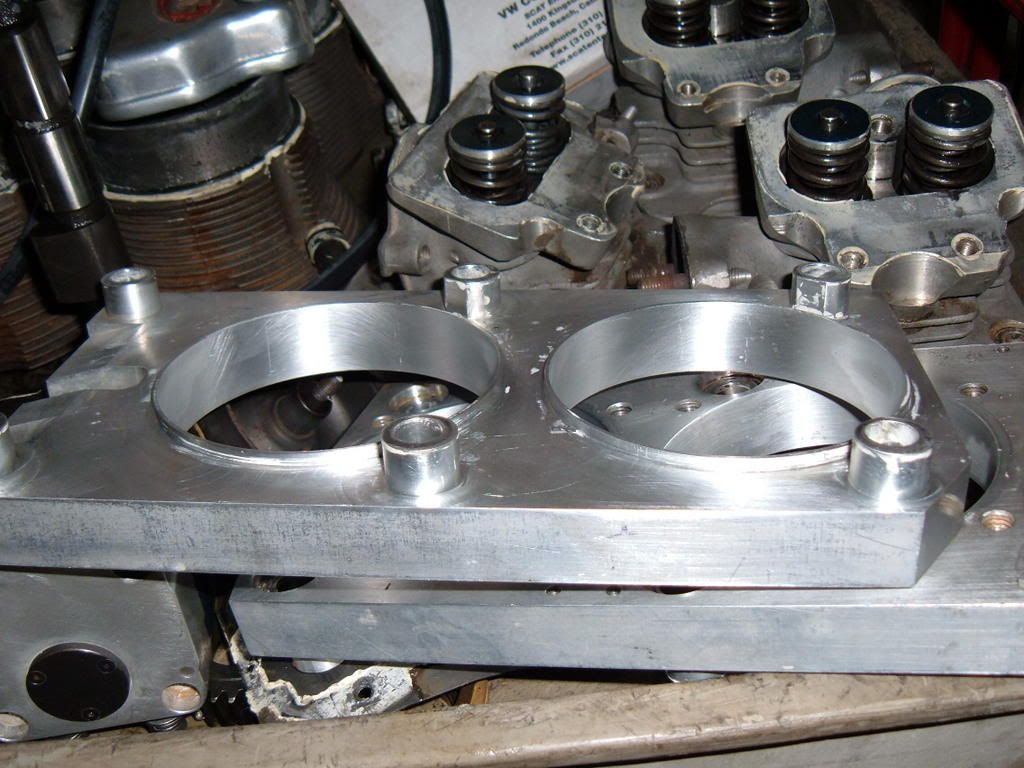

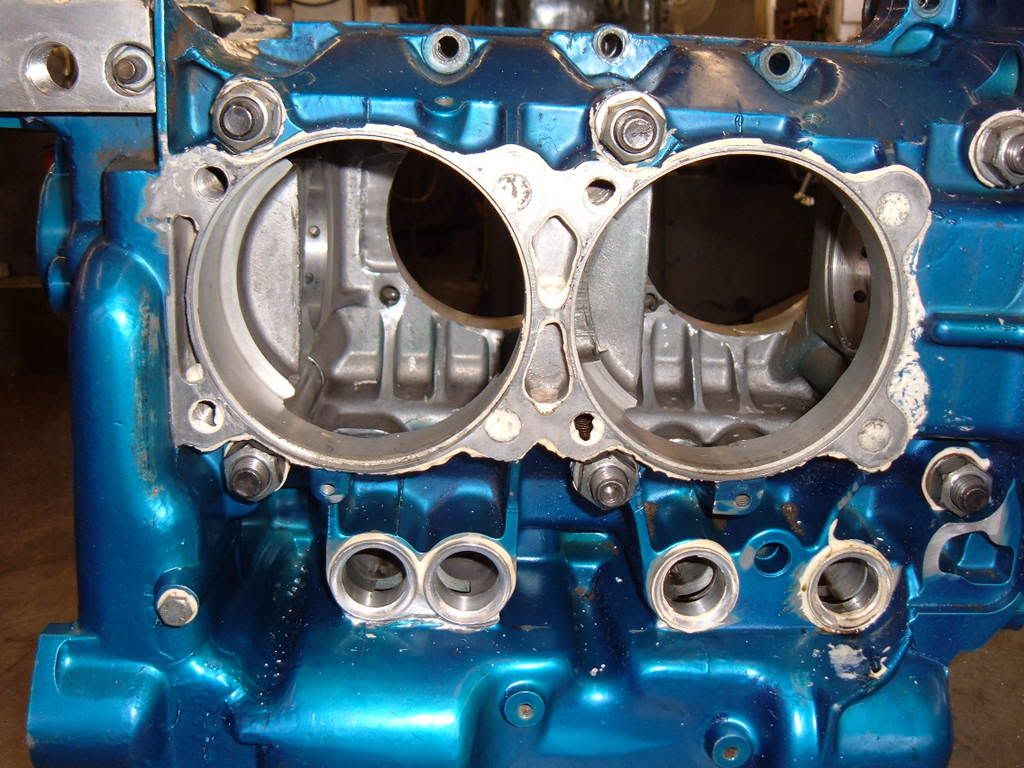

No I don't believe the cas was decked very much, here's a pic of the back side of the plates and a couple of the case. Saw the motor in the buggy, it was a mid engine with a 914 901 5 speed, didn't gets any pics of the buggy.

Stroke was 84mm and the rods were 5.850"

Posted: Sun Jan 06, 2008 4:38 pm

by M-Owen

Thank you Don, I think those pictures were a big help. Do you know who made the plates? It would be nice to just be able to buy some.

Posted: Sun Jan 06, 2008 5:37 pm

by Type 4 Unleashed

M-Owen wrote:Thank you Don, I think those pictures were a big help. Do you know who made the plates? It would be nice to just be able to buy some.

Hi M-Owen

If your talking about the plates just previously pictured, I posted them, and my name is Richard, Don is a nice guy, probally the nicer of the 2 of us...

...but these arn't his pic's.

I know the guy who made these, and was gonna see if I can get him to make me a set, if he doesn't want to much ? These do have some time in them, but he made them for him, so don't know if he will do any more ?

When he had the motor down, I was gonna see if I could have borrowed the plates to have them scanned, then a CNC program made, but the guy that does CNC work had to take off, so wasn't able to get it done that way, at least not yet ?

Here's a Pic for Don, Type lV 66mm.

Posted: Tue Jan 08, 2008 4:45 pm

by M-Owen

Is this forum alright? it seems it has been down alot lately.

Posted: Tue Jan 08, 2008 5:50 pm

by tuna

It's just a few hiccups.

Actually STF is growing larger than anyone could have expected. Doc and his crew are committed to keep STF growing and constantly available. They are working on things "behind the scenes" that should help to minimize the hiccups.

So just hang in there and enjoy!

Tuna

Posted: Tue Jan 08, 2008 6:26 pm

by M-Owen

Cool I thought it might be my computer

Posted: Thu Jan 17, 2008 5:43 am

by M-Owen

Anyone know what size spacer would be required if I wanted to use 911 cylinders and pistons, I would like to use these 98mm pistons and cylinders if I can.

Posted: Sat Jan 19, 2008 2:38 am

by Frallan

M-Owen, you must be more clear on what 98 mm pistons you wish to use but on the other hand the entire calculation is something you would have to come up with yourself, mostly anyway.

Your question is quite vague.

What stroke?

Length of rods?

Compression height of piston?

What piston to cylinder squish are you aiming at? (NA or turbo, compression?)

Take my TIV, it has 82 stroke, 5,9" rods and 28mm compression height, and I have 15 mm spacers under the cylinders.

If I went with 10mm or 12 mm steel or al plate would do just fine and I would anyway need some cylinder spacer.

The T1 with 911 heads is similar. It has 78 stroke and 5,7" rods. A 10 mm steel spacer and 1 mm cylinder shim.

Do you get the principle?

Posted: Sat Jan 19, 2008 2:51 am

by Frallan

[quote="Type 4 Unleashed"][quote="Frallan"]Sorry for another T1 but what about this one way back from 1975?

Ford BDA 4 valve heads and homebuilt everything else.

Just check the crank and rods plus own castings for the chain camdrive.

It runs intermediate belts and then chains to the camhafts.

Now the main point that you might miss if you do not know what to look for is the top of the engine case.

It has been lifted and steel inserts for the main bearing saddles lined together with the steel side plates......any comments about that one?

I heard this engine naturally aspirated with Lucas timed mecahnical injection on 10 000 rpms in 1977, Did I love it? Absolutely lovely.

BUT, Jake sit down, it is converted and watercooled.

[img]

http://i153.photobucket.com/albums/s207 ... 4valve.jpg[/img][/quote]

Frallan, do you know what the stroke on this crank was ?

And no one has commented on the rod bolts being backwards... :lol:[/quote]

Hello, realized I never answered you.

Nope, no idea on stroke but my guess is between 78-82.

The rods are like that probably because it does not matter in which way. No cam interference.

In this latest generation they might have been replaced with Swedish Autoverdi rods. Very popular here as they are Swedish forged and "Carillo quality" but done locally to order.

Same company that sells drysump pumps to Nascar and Prostock teams.

Check them out on

http://www.autoverdi.se/. Very cool display of their pumps. Pass you cursor over the pump....

i.e a very top products

Posted: Sat Jan 19, 2008 9:31 am

by Type 4 Unleashed

Hi Frallan

Thanks for replying. I was wondering about the stroke ? To be able to run 10,000 rpm and live since 1977, and in a Type 1 case. I think is very interesting. As is the guy who builds 47mm stroke Type 4's that turn 14,000 rpm.

The thing is getting these motors to live at these rpm's, then there's getting the valvetrain to work at this rpm. The overhead cam setups makes it alot easier., but the guy who does the 14,000 rpm motors does it with push rods.

I just picked up the full circle crank I pictured earlier, and will try to build something to turn some rpm's. Maybe even with a Turbo.

offset big ends a possibility?

Posted: Wed Jan 23, 2008 12:26 pm

by davek9

Hi, I'm brand new to VW stuff (previously into BMW and Mercedes), but I came across this thread and have been mulling the idea of 911 heads on a Type 4 engine ever since. I may be completely missing something, but I have an idea / questions re: the bore spacing problem.

when having a type 4 crank modified to take type 1 rods (which seems like it's a common thing to do), how do they deal with the difference in big end width between type 1 and 4 rods? the info I've found is that type 4 rod big ends are 25.7mm wide, while type 1's are 22.7mm. So that's a 3mm difference. Is it possible that when regrinding a type 4 crank for type 1 rods they could place the new rod journal grind to the left or right of center by this 3mm difference? wouldn't that then line the rods/pistons up for 911 cylinders on a 118mm spacing adapter plate?

again, I may be way way off here, but from what little I know it seems like this might work, allowing you to keep the 911 cam tower spacing the same and just cut the unused ends off and seal. if you were going to get a new crank for your build it seems like it wouldn't add much in terms of cost. any feedback would be appreciated.

thanks,

dave

Posted: Wed Jan 23, 2008 1:08 pm

by Wally

You obviously did some homework about this, which is a nice chance

Excentering the rod with respect to the piston(pin) would of course give an unequal load and the pin bushing might wear prematurely.

Especially since the engine won't be stock and maybe hold more hp per cylinder than a porsche-6, this is s/th I would not be comfortable with.

Another thing to consider: where did you want to move the cylinder over: inside the head spigot or the case spigot?

So after long searching, you've found a head with equal length studs.. and now you are going to screw that up by excentering this fine balance by moving the studs 3mm off-center...

There's a reason you don't see many of these heads on type 1 or 4's

Posted: Wed Jan 23, 2008 4:21 pm

by davek9

I was thinking I'd move the cylinders over by using an adapter plate on the case. that way I could avoid messing with the heads or the cam towers (cutting out the middle tower and welding the assembly back together is beyond my capabilites). So basically this idea comes out of trying to think of a way to avoid either modifying the cam towers (aside from cutting the unused end off) or modifying the head spigots.

so basically my thinking was to accomplish the 3mm moves by offsetting the connecting rods along the axis of the crank, then offsetting the cylinders on an adapter plate to match. this would mean I could leave everything above the cylinders at 911 spacing.

It sounds like it might not work though. thanks for the feedback. I'm just tossing ideas around in my head right now and haven't yet even starting aquiring parts. and, again, I'm so knew to these motors that I may well be way out of whack altogether.

thanks again for the response,

dave

Posted: Thu Jan 24, 2008 1:19 am

by Piledriver

The T1 rods are offset ~3mm... You might be able you get what you want if you mounted them upside down just on 1/3 or such.

Std T4 rods have no "up".

Posted: Thu Jan 24, 2008 7:27 am

by Wally

Piledriver wrote:The T1 rods are offset ~3mm... You might be able you get what you want if you mounted them upside down just on 1/3 or such.

Std T4 rods have no "up".

I like that idea!

BTW Dave, your idea to use an adapter plate would work I suppose and is better for head stud location as you can use the 911 stud pattern, but I think I like Pile's idea too!

Maybe you could incorporate both idea's and use both?