Ghia Road Course Setup

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Race Prep The Swing Axle

Race Prepping the Swing Axle

All handling discourses for the VW or 356 Porsche must start with the swing axle. For the purposes of this post, we'll separate the production swing axle cars (1938-1968) from the IRS (independent rear suspension) cars.

And yes, we know the swing axle is as independent as the four-joint rear suspension introduced by VW for the 1969 model year. The term IRS has become part of the "damper vs. shock absorber" and "antiroll bar vs. sway bar" conflict.

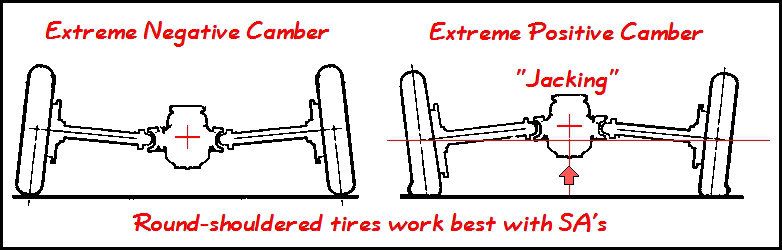

Most VW people know the basic problem with the swing axle -- it "jacks" in sudden fast turns, causing the tires to run on the edges, breaking adhesion, and you can oversteer right off the road.

Add an aft weight bias that needs all the rear tire adhesion it can get in a turn, and the swing axle Porsche's and VW's were oversteering cars.

Swing Axle Control

Porsche himself designed the GP Auto Union cars with a swing axle, but in its last state of refinement, The D-type had the more predictable DeDion design. So, it wasn't like Porsche didn't know the problem. It was just that even for production car racing, the swing axle wasn't all that bad.

And, refinements continued. Mercedes Benz, VW, Porsche, etc., all evolved to the "low pivot" swing axle, a design that minimized jacking. Decambering (lowering the rear suspension by reindexing the torsion bars) also helped by starting off with a little negative camber.

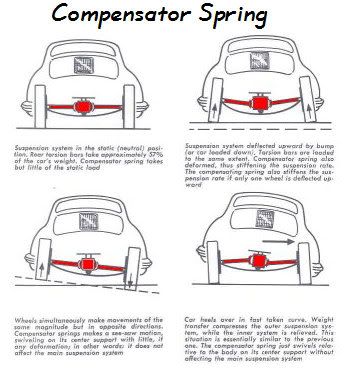

Porsche discovered its classic suspension worked better when the rear torsion bars were softer, and in 1959, reduced the torsion bar diameter, and introduced a "compensator spring" for the Super 90. The Porsche compensator spring wasn't actually a handling aid. It was a supplemental transverse suspension spring that made up for the softer torsion bars without adding roll resistance.

That the compensator spring also resisted the "jacking effect" (the downward swing of the axles as they went into positive camber) made it a camber compensator as well.

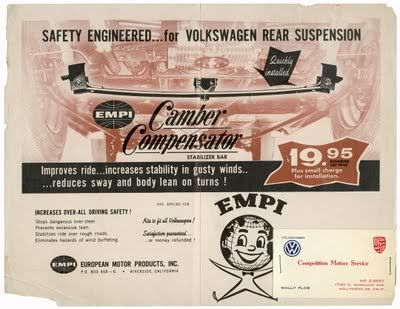

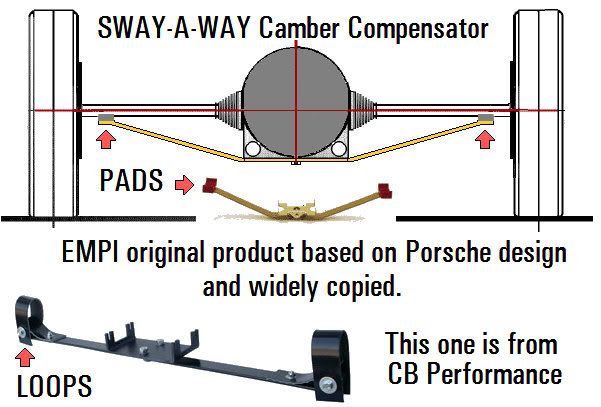

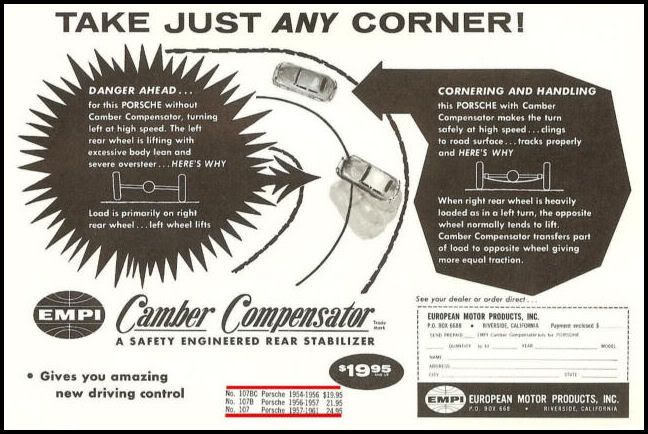

The advantages of the Porsche compensator spring was obvious to Joe Vittone of EMPI (European Motor Products Inc), and by 1960, he was making and selling his camber compensator for VW's. The EMPI product had only one job, resisting jacking.

http://www.cbperformance.com/catalog.asp?ProductID=463

CB Performance camber compensator

As successful as the camber compensator was for the VW, when Porsche offered it as an option on the 1964 356C, enough Porsche customers didn't buy, and the spring was soon discontinued! That didn't deter EMPI, who made up for the lack of the factory part, and smart Porsche pushers bought them.

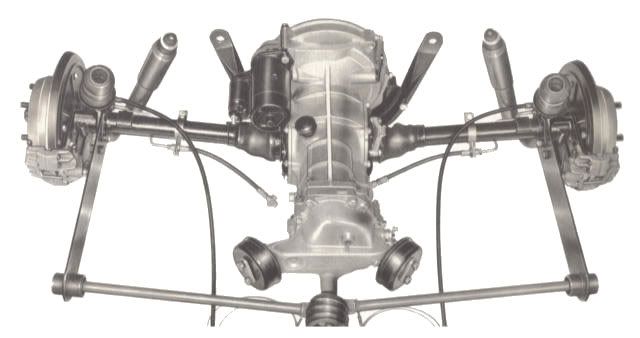

Porsche 356C rear suspension. Look familiar?

When VW softened its rear torsion bars for the 1967 and '68 cars to improve handling, instead of an compensator spring, it designed something better -- the Z-bar.

The Z-bar is covered and commented on here:

http://www.shoptalkforums.com/viewtopic ... 1&t=122651

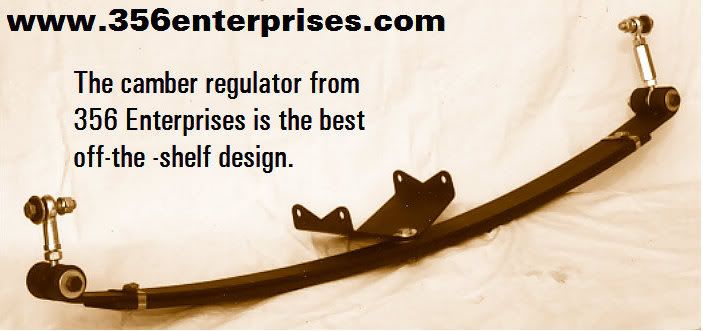

Vic Skirmants of 356 Enterprises took the best of the compensator spring and the Z-bar and developed this highly effective "camber regulator" device for the 356.

If you happened to see the winning SCCA E-production 356's in the paddock up on jack stands back in the day, the most striking thing about them was there was little to no droop to the rear axles. For those who need some rear suspension travel for the street, this isn't practical.

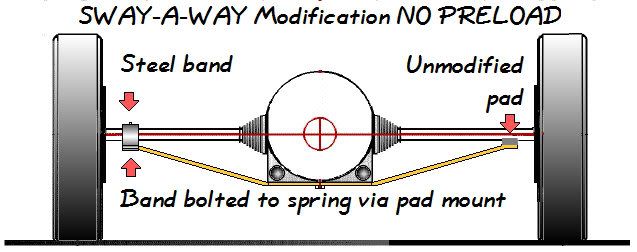

For racing purposes, the less a swing axle swings, the better. The purpose behind Vic's spring can be replicated -- somewhat -- with this modified Sway-A-Way compensator.

The idea is to let the transverse spring act to resist both up and down movements and keep the rear axles as straight as possible in relation to each other. Yes, using the Sway-A-Way spring in this manner adds some rear roll stiffness, but makes up for it with a much more predictable feel from the rear suspension.

You must modify both ends of the Sway-A-Way spring for this to work ... and size your steel end bands so there is no preload.

You have to run as much negative camber up front as you can if you use this trick. The 356's typically run at least 3 degrees. 356 Enterprises sells a specially modified front stub axle assembly that gives 3.5 degrees.

Here's the three stages of swing-axle setup, from mild to wild.

STAGE 1: Stock ride height

1. Factory spec four-wheel alignment

2. Heavy duty shocks all round

3. 19mm front sway bar

4. Rear camber compensator

5. Round-shouldered radial tires

STAGE 2: Lowered (adj. front axle beam, decambered rear suspension)

1. Factory spec four wheel alignment

2. Adjustable shocks

3. Adjustable front sway bar links

4. Rear camber compensator with preload adjustments

5. Racing radials

STAGE 3: Coil spring suspension

1. Machined front kingpin-linkpin assemble for front negative camber

2. Adjustable coil-over shocks (coils replacing torsion bars)

3. Adjustable rear spring plates pivot from orig. torsion bar point.

4. Adjustable Z-bar for rear suspension

5. Widest possible wheels, racing slicks

Next: Race Prep The IRS

Last edited by FJCamper on Tue Oct 27, 2009 9:30 am, edited 1 time in total.

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Book Learning

Two excellent books specific to our VW+Porsche mechanics are:

How to Modify VW Beetle Suspension, Brakes, and Chassis For High Performance

by James Hale (Veloce Publishing PLC) ISBN 1-9011295-80-X

Porsche 356 Performance Handbook

by Duane Spencer (Motorbooks International) ISBN 0-87938-417-4

We return you now to ShopTalk.

-

VWdudeCory

- Posts: 1

- Joined: Wed Nov 11, 2009 1:48 pm

Re: Ghia Road Course Setup

Thanks for all the info! I got redirected here from thesamba and this is a real nice guide for the build I am doing this winter on my ghia!

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Ghia Road Course Setup

Road Race Prep the IRS

Road Racing vs Drag Transaxles

The VW/Porsche combo transmission, differential, and axle assembly is properly called a transaxle. But often we call them transmissions or just trannys.

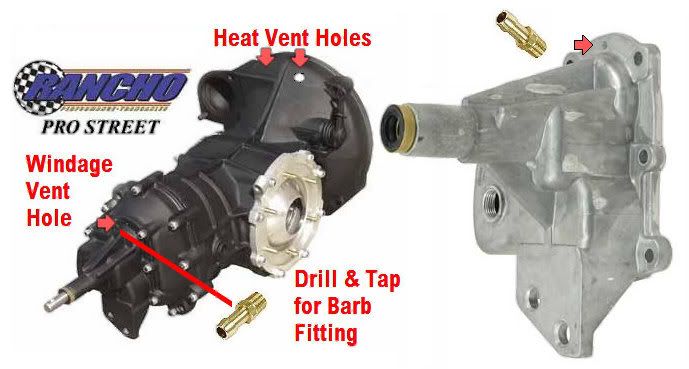

The bad news is stock VW or Porsche transaxles break in all kinds of interesting ways on even medium-powered drag cars. The good news is stock VW or Porsche transaxles can take road racing reasonably well and survive. The same modifications that strengthen a drag tranny work great on a road course car too, of course. Those are well known. Here's what we have in our Rancho Performance "ProComp" transaxle for our IRS No. 53 car.

Super Differential (4 spider gears instead of two)

Aluminum Side Cover (stops flexing)

Welded 3rd & 4th Gears

Steel Shift Forks

Hardened Keys

4:125 Ring & Pinion

Close Ratio 3rd & 4th

The Ring & Pinion ratio is chosen either for acceleration or top speed with a given tire diameter. "Close ratio" gears are to keep engine speed up when shifting.

When you shift gears, you typically lift off the gas for an instant, and your engine RPM slows down. Plus, the next higher gear usually requires more power to keep the car accelerating. Combine these two facts and on an upshift, you slow down some before engine RPM's build up again.

Racers learn to compensate with the "power shift," the technique of upshifting without fully lifting off the accelerator pedal.

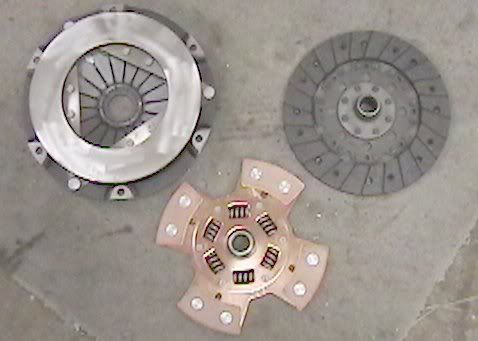

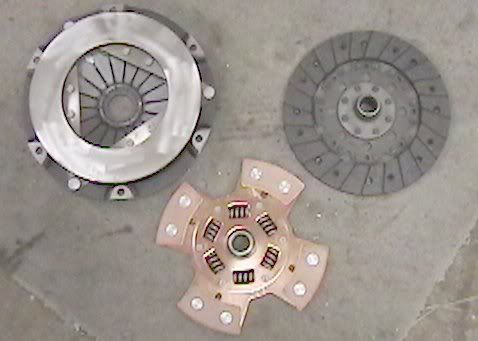

But watch out. You can upshift so fast you can "beat" (override) the synchronizers. The rotational speed and mass of the clutch disk can affect gear engagement. This is one reason why the super-light puck style disks can shift so fast.

You want the engine to stay in the "power band" which is apexed in the RPM range at which the most torque and power is made. When you upshift, watch your tach. You may see a 1500-2000 RPM loss and you want to stay within the band.

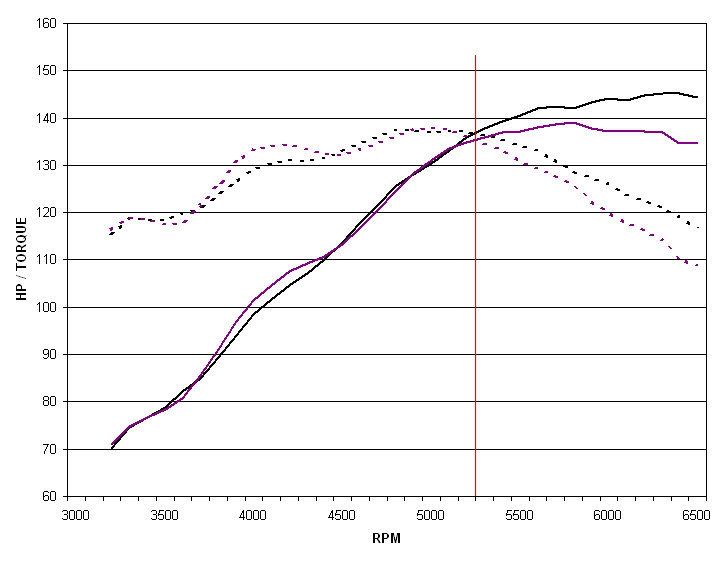

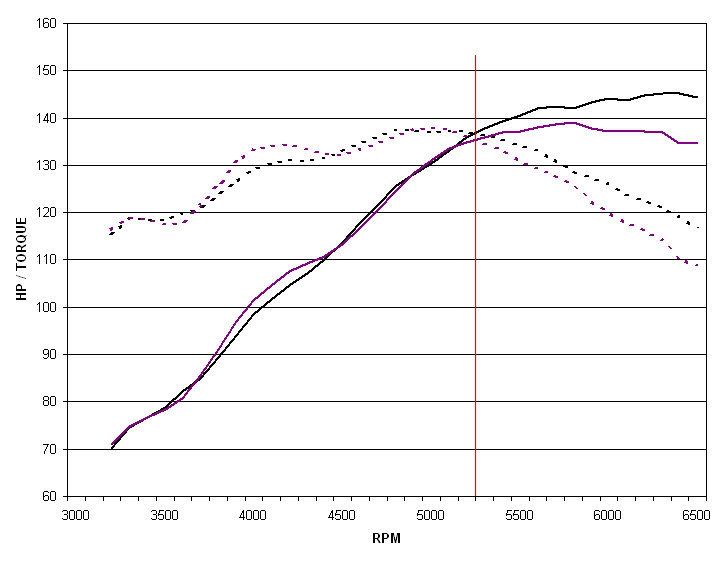

Above: A modified 356 Porsche engine producing max power and torque at about 5200 RPM. A stock engine would apex at about 4000 RPM. The power band for this engine begins about 4000 RPM and drops off after 5500 RPM. The best shift point for this engine is 5200 RPM.

Which is why we want to build engines with as wide a power band as possible. This conflicts (of course) with the nature of high performance engines. As they get more powerful, the power band narrows, and moves up the scale. Some highly tuned engines have a 1000 RPM band at 6000-7000 RPM. They dyno great but are not streetable.

Street engines are designed to have wide, "flat" (little or no peaking) power bands so drivers can be in the wrong gear and still putt-putt around town. Wide ratio gearing is also common for street cars. VW traditionally had 1st and second as close mathematical steps, so that the upshift from 1st to 2nd lost little engine RPM. The worst gap was between 2nd and 3rd, and then the next gap between 3rd and 4th.

For road racing, we use 1st mainly to get rolling out of the paddock, and never engage it again. 2nd might be used on hairpins, and 3rd-4th are used all the time.

Gear ratios really affect how a car feels. But feel and stopwatch performance are not always the same thing. The Porsche 356 had more performance-oriented gear ratios than the VW, and quarter-mile max throttle upshifts felt good, the engine staying in the power band just as each gear maxed out.

Car & Driver Magazine reported this in a drag-race test between a stock 356A Speedster and a stock single-carb Karmann Ghia back in 1972:

"Despite the standard Ghia's 10-horsepower deficit to the Speedster, smog gear and 130 extra pounds, the Ghia didn't let down its backers by much in the acceleration tests (where the Speedster group was expecting a knock-out). It proved to be just over a second slower than the Speedster at the end of the quarter-mile."

The Ghia got down the strip, despite the big gearing gaps. But don't miss the point. The Porsche could be driven more smoothly, less driver effort.

Venting & Cooling the VW Transaxle

VW transaxles have no provision for cooling, except by conducting heat out via the magnesium alloy case.

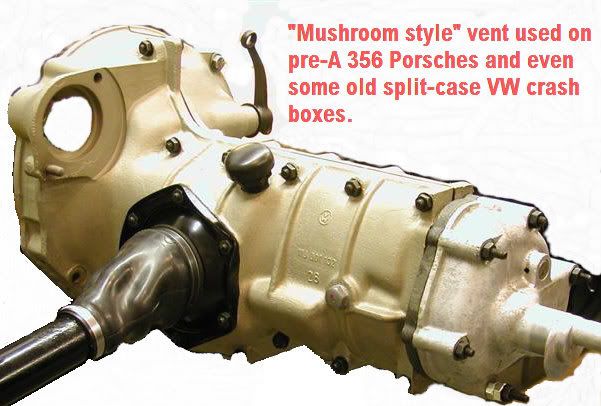

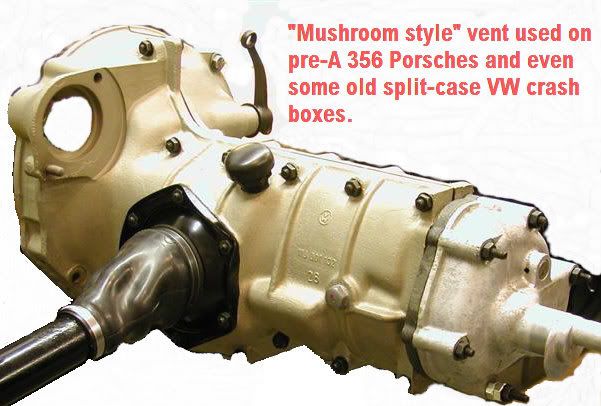

Porsche 917's had pump-fed oil to keep their transaxles alive, plus an oil cooler! That's because racing trannys get hot, especially for road racing. Even back in the 356 days (on various models) Porsche provided for cooling by casting an open slot vent atop the bell housing for clutch heat to escape, and fitted a mushroom-shaped windage vent to the transaxle.

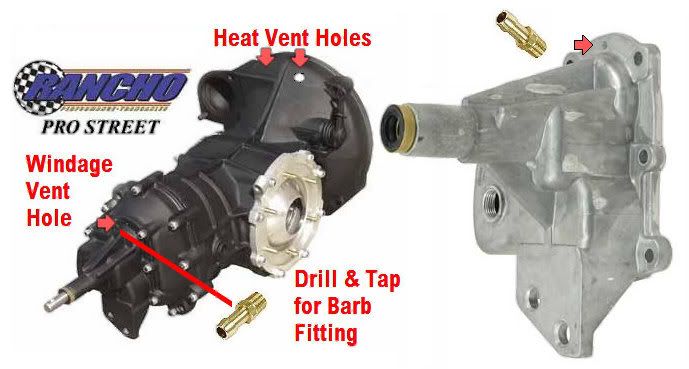

The vent on the stock VW is a single too-small hole in the nose cone (often closed by dirt!), and is critical. High internal pressure in the "front" of the transaxle case (opposite the bell housing) impedes the splash lubrication reaching the forward gear shaft bearing.

If you'll remove your nose cone and drill and tap the existing vent hole for a quarter-inch ID brass fitting, you can attach a length of fuel line to it, terminated by a reversed fuel filter. This allows pressure out but stops dust from coming in.

Air-cooling holes can be drilled in the top of the bell housing -- and don't forget a couple in the bottom to let cool air in.

Transaxle Oil for Racing

Synthetic gear oil has proven itself to perform as well if not better than conventional oil. It's best feature might be that you can run a lighter weight oil (75-90w vs 90w) and not harm anything -- and the lighter the oil, the more power you free up.

No second hand info here. We ran synthetic for three seasons in our IRS 4.86 R&P "drag" transaxle for 53, and it was, no pun intended, slick. The 4.86 gave us brutally quick acceleration, which was fine for the autocrosses we were running, but hampered our top end on the road courses.

I never knew the oil's brand. It was in the transaxle when we bought it.

Being the conservative type, on install of our ProComp 4.12 for better top end, I filled it with Castrol 90w hypoid gear oil and my personal favorite, moly grease (Molybdenum disulfide) additive. Never a problem, and that's after hours of full throttle loads on the major southeastern tracks. Moly is always good stuff. It will actually "heal" pitting in steel gears as it fills and smooths them.

Finally, when we had the transaxle built for 261, our swing-axle Carrera Panamericana Ghia, I experimented and filled it with Valvoline DuraBlend (synthetic blend) 80-90w. Again, no problems.

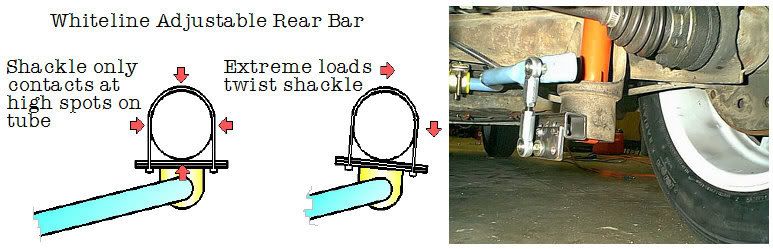

IRS Sway and Torsion Bars

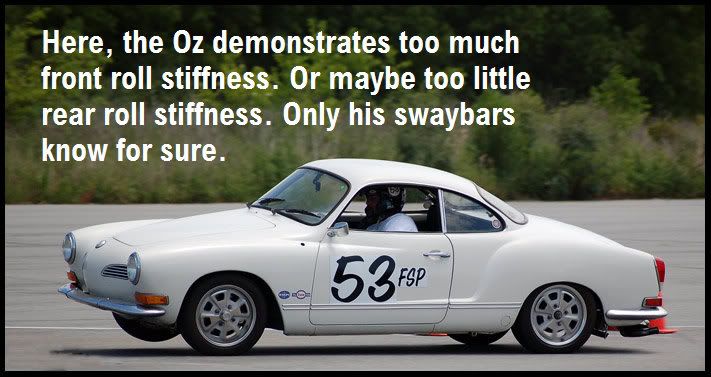

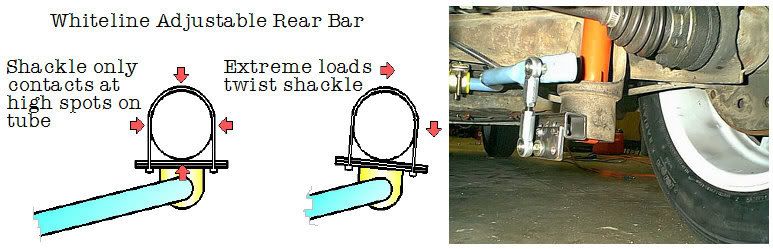

We use a nonadjustable 19mm rear bar, or an adjustable 22mm Whiteline rear bar, and sometimes, no rear bar at all. It all depends on the track. A rule of thumb is the faster you go, the less oversteer you want, and on our type of car, rear bars promote oversteer.

As we got faster, upgrading from a 1.6 to a 2.2 liter engine, high speed handling became more and more important.

Above: nonadjustable bar.

Above: Whiteline Rear Bar with end links.

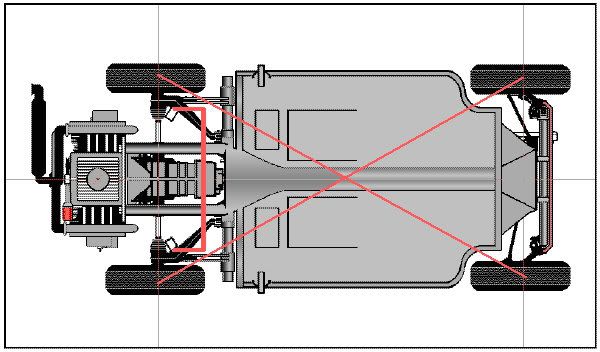

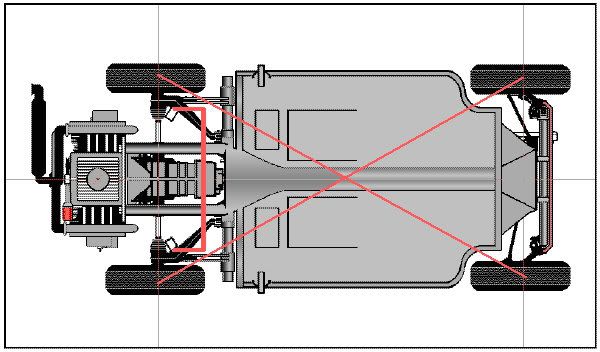

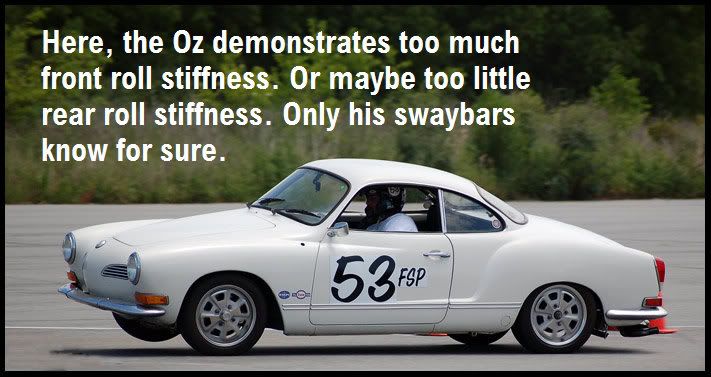

The front bar affects the rear bar and vice versa. This is called the "X-effect" and means loads from the right front wheel affect the left rear wheel, etc.

VW's and Porsches tend to lift the inside front wheel while cornering hard, which means while it is in the air, you have one whole tire that is not providing traction or steering.

All else being equal, a rear bar tends to keep both front tires on the ground. The heavily loaded outside rear tire, via the X-effect, transfers loading to the airborne front inside tire.

The thicker a sway bar, the more roll resistance it offers. But more is not always better. Porsche learned back in 1959 that decreasing the rear roll resistance made their cars handle better. VW followed suit on this in 1967 with softer rear torsion bars.

This means for road racing, the stiffer rear torsion bars intended for dune buggies are not always desirable. Good stock bars, indexed for the ride height you want, are best.

The only reason to have stiffer torsion bars front or rear is to resist bottoming out on very high speed dips, or on fast, banked tracks. If you race a lot under either circumstance, a slightly stiffer torsion bar is a good thing.

Hard springing (all by itself) is not the way to tune handling. You want to get your roll resistance from sway bars, and keep your tires planted with good shocks.

Coil-over shocks with adjustable spring rates are the easiest (and most expensive) way to tune your suspension. Coil-overs can replace torsion bars totally, if you want to go that route. And the results are superior. For instance, you can stiffen the front roll resistance via the springs and use less front sway bar, and then (with no rear bar) begin to adjust the rear roll until you have exactly the amount of understeer you want at high speed.

944 Rear Semi-Trailing Arms (or diagonal arms, if you prefer)

The VW Type 1 rear IRS suspension was exported right off the VW to the Porsche 924/944 because it worked so well. And the 924/944 was hailed as a handler. (The 924/944 was never a "Porsche" anyway. It was an Audi. And the 914 was badged a "VW-Porsche" in Europe, but a Porsche stateside.)

To distance itself from its common VW heritage, Porsche eventually replaced the 944's steel rear diagonal arms with more exotic aluminum arms. The weight (about 16lbs), suspension geometry (and handling) stayed the same, but for VW owners who discovered the parts were interchangeable, the bragging rights were good. The most advantageous thing about a 944 rear suspension swap is being able to use 944 rear disk brakes.

Flipping and Rewelding Diagonal Arms

VW fabricators learned to keep rear camber reasonable in extreme lowering, the diagonal arms could be reversed right for left, with some skillful welding mods to the arms to make it all line up right. Some advice for road racers. You shouldn't be lowering your Ghia (or Bug) this much. It's for cafe racers, strictly cosmetic.

There is a reason why -- too much rear squat on acceleration.

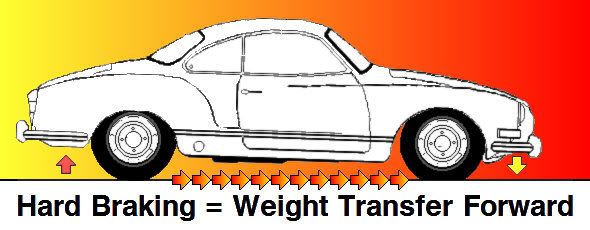

The VW suspension, swing axle or IRS, has no anti-squat to counter acceleration, and for that matter, no anti-dive to counter hard braking. If you lower too much, and you have even a low-profile deep sump, you are going to bump it against the road on hard acceleration.

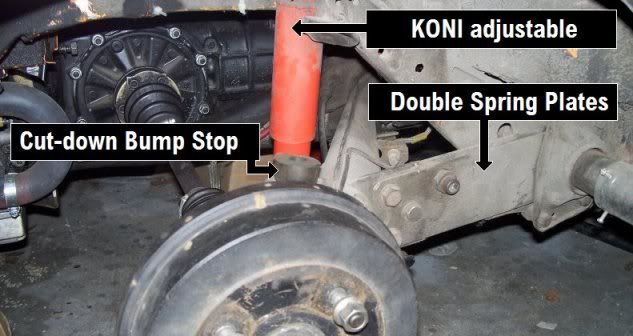

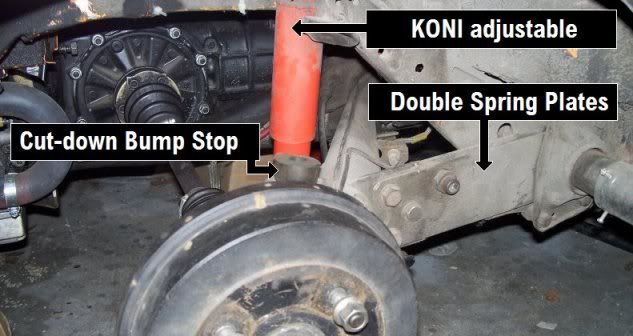

Above: This view (from our IRS Ghia) shows how to cut down your bump stops for increased rear suspension travel and our 3-way Koni adjustable shocks in place.

Adjustable Spring Plates

For the IRS, the dual spring plate must be replaced with a single adjustable plate, which requires a shorter (stiffer) torsion bar. VW softened the rear bars in 1967, and then really softened them again for the IRS (1969 model year) and made them longer.

This means going to adjustable plates requires some increase in spring rate. Adjustable plates are actually worth the work, because they give you on-the-spot ride height and weight-jacking capability.

We don't use them because we have the rear ride height we want, and our handling adjustments and calculations are predicted on the stock rear IRS torsion bar.

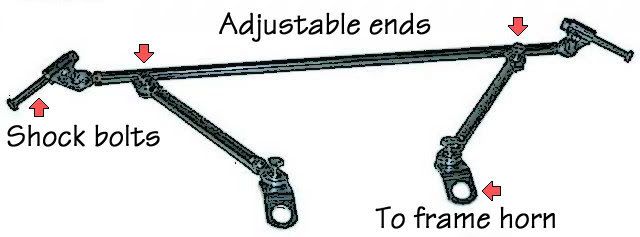

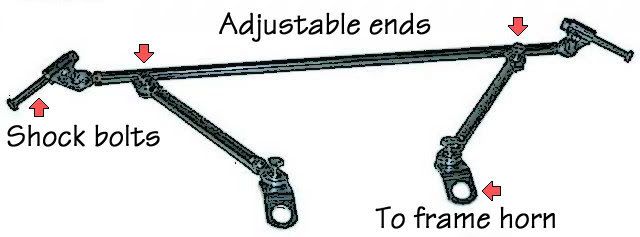

Kafer Bars & Other Reinforcements

The Kafer bar (Kafer being the original German nickname for the Bug) is an easy to install triangulation device that braces the shock tower uprights to the transmission mount. Wheel hop (caused by flexing) is usually totally eliminated by the Kafer bar. As is frame horn welds cracking. The Kafer bar works as well on a swing axle as it does an IRS.

The alternative to the Kafer is to tie the frame horns together with a solid steel brace, and strap the transaxle down front and rear. We used the Kafer on 261 and the bracing and strapping on 53. We know the braces/strapping work on 53, because in our autocross days, with our drag-race starts, wheel hop was never an issue.

CV Joints

The stock VW CV Type 1 joints can handle about 125-130 HP if you're drag racing. This is just an approximate. I know some of you may be using them with more power than that, and a few of you might have broken stock CV's with less than that, I'm just related what we were told by Porsche in 1976 when I was being factory-trained on the then-new 924.

The 924 CV is actually the Type IV joint for the Bus and 411. It was considered good enough for a Porsche that might be raced.

However, the Porsche 930 CV joint is better in every way than the stock VW Type 1 joint, stronger and with a greater range of motion, but the caveat applies here of what you need and can afford vs what you may want.

For road racing, the stock CV's can support about 150-200 HP if you don't do drag race starts. Remember, on a road course, you are already in gear and at speed when the green flag drops.

Next BRAKES

Road Racing vs Drag Transaxles

The VW/Porsche combo transmission, differential, and axle assembly is properly called a transaxle. But often we call them transmissions or just trannys.

The bad news is stock VW or Porsche transaxles break in all kinds of interesting ways on even medium-powered drag cars. The good news is stock VW or Porsche transaxles can take road racing reasonably well and survive. The same modifications that strengthen a drag tranny work great on a road course car too, of course. Those are well known. Here's what we have in our Rancho Performance "ProComp" transaxle for our IRS No. 53 car.

Super Differential (4 spider gears instead of two)

Aluminum Side Cover (stops flexing)

Welded 3rd & 4th Gears

Steel Shift Forks

Hardened Keys

4:125 Ring & Pinion

Close Ratio 3rd & 4th

The Ring & Pinion ratio is chosen either for acceleration or top speed with a given tire diameter. "Close ratio" gears are to keep engine speed up when shifting.

When you shift gears, you typically lift off the gas for an instant, and your engine RPM slows down. Plus, the next higher gear usually requires more power to keep the car accelerating. Combine these two facts and on an upshift, you slow down some before engine RPM's build up again.

Racers learn to compensate with the "power shift," the technique of upshifting without fully lifting off the accelerator pedal.

But watch out. You can upshift so fast you can "beat" (override) the synchronizers. The rotational speed and mass of the clutch disk can affect gear engagement. This is one reason why the super-light puck style disks can shift so fast.

You want the engine to stay in the "power band" which is apexed in the RPM range at which the most torque and power is made. When you upshift, watch your tach. You may see a 1500-2000 RPM loss and you want to stay within the band.

Above: A modified 356 Porsche engine producing max power and torque at about 5200 RPM. A stock engine would apex at about 4000 RPM. The power band for this engine begins about 4000 RPM and drops off after 5500 RPM. The best shift point for this engine is 5200 RPM.

Which is why we want to build engines with as wide a power band as possible. This conflicts (of course) with the nature of high performance engines. As they get more powerful, the power band narrows, and moves up the scale. Some highly tuned engines have a 1000 RPM band at 6000-7000 RPM. They dyno great but are not streetable.

Street engines are designed to have wide, "flat" (little or no peaking) power bands so drivers can be in the wrong gear and still putt-putt around town. Wide ratio gearing is also common for street cars. VW traditionally had 1st and second as close mathematical steps, so that the upshift from 1st to 2nd lost little engine RPM. The worst gap was between 2nd and 3rd, and then the next gap between 3rd and 4th.

For road racing, we use 1st mainly to get rolling out of the paddock, and never engage it again. 2nd might be used on hairpins, and 3rd-4th are used all the time.

Gear ratios really affect how a car feels. But feel and stopwatch performance are not always the same thing. The Porsche 356 had more performance-oriented gear ratios than the VW, and quarter-mile max throttle upshifts felt good, the engine staying in the power band just as each gear maxed out.

Car & Driver Magazine reported this in a drag-race test between a stock 356A Speedster and a stock single-carb Karmann Ghia back in 1972:

"Despite the standard Ghia's 10-horsepower deficit to the Speedster, smog gear and 130 extra pounds, the Ghia didn't let down its backers by much in the acceleration tests (where the Speedster group was expecting a knock-out). It proved to be just over a second slower than the Speedster at the end of the quarter-mile."

The Ghia got down the strip, despite the big gearing gaps. But don't miss the point. The Porsche could be driven more smoothly, less driver effort.

Venting & Cooling the VW Transaxle

VW transaxles have no provision for cooling, except by conducting heat out via the magnesium alloy case.

Porsche 917's had pump-fed oil to keep their transaxles alive, plus an oil cooler! That's because racing trannys get hot, especially for road racing. Even back in the 356 days (on various models) Porsche provided for cooling by casting an open slot vent atop the bell housing for clutch heat to escape, and fitted a mushroom-shaped windage vent to the transaxle.

The vent on the stock VW is a single too-small hole in the nose cone (often closed by dirt!), and is critical. High internal pressure in the "front" of the transaxle case (opposite the bell housing) impedes the splash lubrication reaching the forward gear shaft bearing.

If you'll remove your nose cone and drill and tap the existing vent hole for a quarter-inch ID brass fitting, you can attach a length of fuel line to it, terminated by a reversed fuel filter. This allows pressure out but stops dust from coming in.

Air-cooling holes can be drilled in the top of the bell housing -- and don't forget a couple in the bottom to let cool air in.

Transaxle Oil for Racing

Synthetic gear oil has proven itself to perform as well if not better than conventional oil. It's best feature might be that you can run a lighter weight oil (75-90w vs 90w) and not harm anything -- and the lighter the oil, the more power you free up.

No second hand info here. We ran synthetic for three seasons in our IRS 4.86 R&P "drag" transaxle for 53, and it was, no pun intended, slick. The 4.86 gave us brutally quick acceleration, which was fine for the autocrosses we were running, but hampered our top end on the road courses.

I never knew the oil's brand. It was in the transaxle when we bought it.

Being the conservative type, on install of our ProComp 4.12 for better top end, I filled it with Castrol 90w hypoid gear oil and my personal favorite, moly grease (Molybdenum disulfide) additive. Never a problem, and that's after hours of full throttle loads on the major southeastern tracks. Moly is always good stuff. It will actually "heal" pitting in steel gears as it fills and smooths them.

Finally, when we had the transaxle built for 261, our swing-axle Carrera Panamericana Ghia, I experimented and filled it with Valvoline DuraBlend (synthetic blend) 80-90w. Again, no problems.

IRS Sway and Torsion Bars

We use a nonadjustable 19mm rear bar, or an adjustable 22mm Whiteline rear bar, and sometimes, no rear bar at all. It all depends on the track. A rule of thumb is the faster you go, the less oversteer you want, and on our type of car, rear bars promote oversteer.

As we got faster, upgrading from a 1.6 to a 2.2 liter engine, high speed handling became more and more important.

Above: nonadjustable bar.

Above: Whiteline Rear Bar with end links.

The front bar affects the rear bar and vice versa. This is called the "X-effect" and means loads from the right front wheel affect the left rear wheel, etc.

VW's and Porsches tend to lift the inside front wheel while cornering hard, which means while it is in the air, you have one whole tire that is not providing traction or steering.

All else being equal, a rear bar tends to keep both front tires on the ground. The heavily loaded outside rear tire, via the X-effect, transfers loading to the airborne front inside tire.

The thicker a sway bar, the more roll resistance it offers. But more is not always better. Porsche learned back in 1959 that decreasing the rear roll resistance made their cars handle better. VW followed suit on this in 1967 with softer rear torsion bars.

This means for road racing, the stiffer rear torsion bars intended for dune buggies are not always desirable. Good stock bars, indexed for the ride height you want, are best.

The only reason to have stiffer torsion bars front or rear is to resist bottoming out on very high speed dips, or on fast, banked tracks. If you race a lot under either circumstance, a slightly stiffer torsion bar is a good thing.

Hard springing (all by itself) is not the way to tune handling. You want to get your roll resistance from sway bars, and keep your tires planted with good shocks.

Coil-over shocks with adjustable spring rates are the easiest (and most expensive) way to tune your suspension. Coil-overs can replace torsion bars totally, if you want to go that route. And the results are superior. For instance, you can stiffen the front roll resistance via the springs and use less front sway bar, and then (with no rear bar) begin to adjust the rear roll until you have exactly the amount of understeer you want at high speed.

944 Rear Semi-Trailing Arms (or diagonal arms, if you prefer)

The VW Type 1 rear IRS suspension was exported right off the VW to the Porsche 924/944 because it worked so well. And the 924/944 was hailed as a handler. (The 924/944 was never a "Porsche" anyway. It was an Audi. And the 914 was badged a "VW-Porsche" in Europe, but a Porsche stateside.)

To distance itself from its common VW heritage, Porsche eventually replaced the 944's steel rear diagonal arms with more exotic aluminum arms. The weight (about 16lbs), suspension geometry (and handling) stayed the same, but for VW owners who discovered the parts were interchangeable, the bragging rights were good. The most advantageous thing about a 944 rear suspension swap is being able to use 944 rear disk brakes.

Flipping and Rewelding Diagonal Arms

VW fabricators learned to keep rear camber reasonable in extreme lowering, the diagonal arms could be reversed right for left, with some skillful welding mods to the arms to make it all line up right. Some advice for road racers. You shouldn't be lowering your Ghia (or Bug) this much. It's for cafe racers, strictly cosmetic.

There is a reason why -- too much rear squat on acceleration.

The VW suspension, swing axle or IRS, has no anti-squat to counter acceleration, and for that matter, no anti-dive to counter hard braking. If you lower too much, and you have even a low-profile deep sump, you are going to bump it against the road on hard acceleration.

Above: This view (from our IRS Ghia) shows how to cut down your bump stops for increased rear suspension travel and our 3-way Koni adjustable shocks in place.

Adjustable Spring Plates

For the IRS, the dual spring plate must be replaced with a single adjustable plate, which requires a shorter (stiffer) torsion bar. VW softened the rear bars in 1967, and then really softened them again for the IRS (1969 model year) and made them longer.

This means going to adjustable plates requires some increase in spring rate. Adjustable plates are actually worth the work, because they give you on-the-spot ride height and weight-jacking capability.

We don't use them because we have the rear ride height we want, and our handling adjustments and calculations are predicted on the stock rear IRS torsion bar.

Kafer Bars & Other Reinforcements

The Kafer bar (Kafer being the original German nickname for the Bug) is an easy to install triangulation device that braces the shock tower uprights to the transmission mount. Wheel hop (caused by flexing) is usually totally eliminated by the Kafer bar. As is frame horn welds cracking. The Kafer bar works as well on a swing axle as it does an IRS.

The alternative to the Kafer is to tie the frame horns together with a solid steel brace, and strap the transaxle down front and rear. We used the Kafer on 261 and the bracing and strapping on 53. We know the braces/strapping work on 53, because in our autocross days, with our drag-race starts, wheel hop was never an issue.

CV Joints

The stock VW CV Type 1 joints can handle about 125-130 HP if you're drag racing. This is just an approximate. I know some of you may be using them with more power than that, and a few of you might have broken stock CV's with less than that, I'm just related what we were told by Porsche in 1976 when I was being factory-trained on the then-new 924.

The 924 CV is actually the Type IV joint for the Bus and 411. It was considered good enough for a Porsche that might be raced.

However, the Porsche 930 CV joint is better in every way than the stock VW Type 1 joint, stronger and with a greater range of motion, but the caveat applies here of what you need and can afford vs what you may want.

For road racing, the stock CV's can support about 150-200 HP if you don't do drag race starts. Remember, on a road course, you are already in gear and at speed when the green flag drops.

Next BRAKES

Last edited by FJCamper on Thu Dec 03, 2009 2:05 pm, edited 1 time in total.

- DORIGTT

- Posts: 614

- Joined: Thu May 18, 2000 12:01 am

Re: Ghia Road Course Setup

This is awesome information. I lurk this thread for updates and you do not let me down.

Thanks for sharing your experience with us.

Kevin

Thanks for sharing your experience with us.

Kevin

-

Mabbo

- Posts: 453

- Joined: Wed May 14, 2003 4:48 am

Re: Ghia Road Course Setup

very interesting read

im looking forward to the brake section

im looking forward to the brake section

-

dragvw

- Posts: 8

- Joined: Thu Nov 05, 2009 3:47 pm

Re: Ghia Road Course Setup

This is the best I have seen on suspensions for bugs and I have all the books that is mentioned here.

Good work. looking for updates.

Hermann

Good work. looking for updates.

Hermann

-

wjoef

- Posts: 4

- Joined: Sun Nov 15, 2009 11:42 am

Re: Ghia Road Course Setup

FJCamper -

Thank you for sharing.

Thank you for sharing.

Mine: 1966 Karmann Ghia Coupe - in pieces and slooooowly being put back together

Wife's: 1973 Standard Beetle, her daily driver

Karmann Ghia - a german alfa-romeo or an italian porsche?

Wife's: 1973 Standard Beetle, her daily driver

Karmann Ghia - a german alfa-romeo or an italian porsche?

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Ghia Road Course Setup

BRAKES

Preface note. The VW Ghia is such a light car that it's brake demands are only moderate, and most of the extremes in power assisit, brake proportioning, etc., are just not that critical.

BRAKE BASICS ON REAR-ENGINE CARS

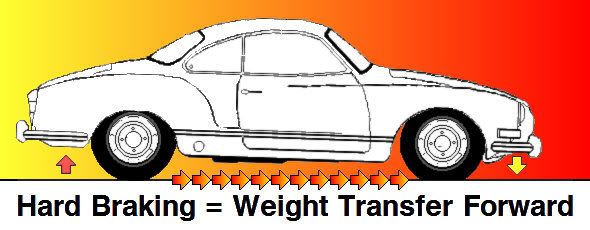

The rear-engine car, with more than half its weight in the rear, has a distinct braking advantage. As the weight transfers forward in braking, all four wheels are loaded, making the rear brakes work harder than on a front-engined, front-heavy car.

Even though rear-engined, in hard braking, about 70% of the total VW or Porsche braking effort is still borne by the front brakes!

Front-engined cars obviously overwork their front brakes, which might explain why the Ghia can get by with proportionally smaller brakes all the way around, than say, the Mustang beside it. Smaller, lighter, brakes mean less unsprung weight as well.

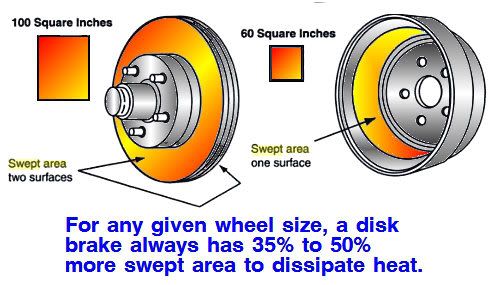

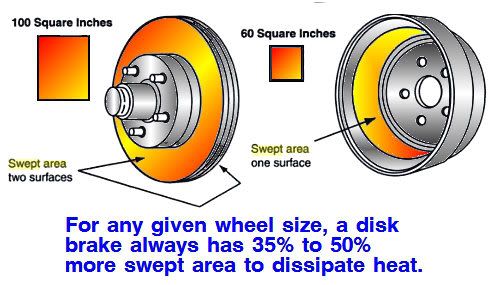

THE SWEPT AREA

Also, with the Ghia being a light car to begin with, the factor of "swept-area" versus weight comes into play. The swept area is the friction area on a disk or drum that contacts the brake pad or shoe.

Generally speaking, the larger the swept area, the better the brakes work. Disk brakes have an advantage, as they have a swept area on both sides, whereas drums are considered to have a single area, even through there are two shoes.

VW's have a very good swept area to vehicle weight ratio, in fact, falling even today into the performance brake range. Actually, a 1972 Ghia, box stock, could stop in a shorter distance from 70mph than a 911.

The problem was in constantly repeating the stop, and increasing braking efficiency over 70mph. Which can be done.

STOCK BRAKES? NOT SO BAD

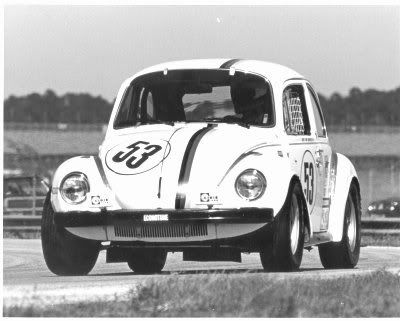

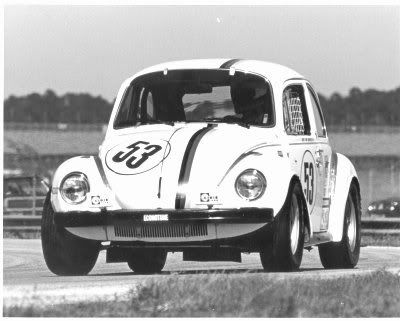

We learned something useful about VW brakes in our 1973 Herbie the Super Bug foray into IMSA B-Sedan Racing in 1976. They are better than expected.

The B-Sedan rules didn't allow for us to change the brakes (except pad or shoe material) so we had to run stock. For the 1973 Super Bug, that meant 2-pin ATE calipers and solid 10.9-inch (277mm) rotors (9.5mm thickness), same as the Ghias had, and rear 9-inch drum brakes, same as on the contemporary Bugs and Ghias.

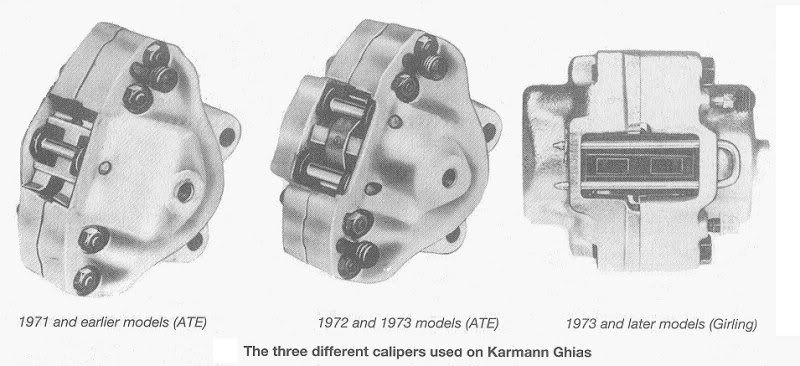

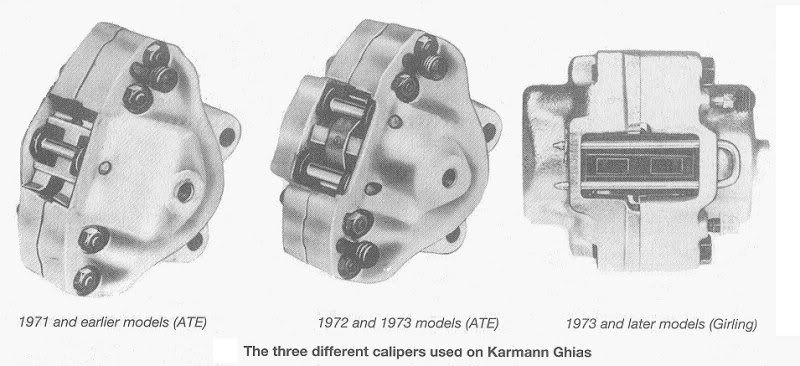

The AT of ATE, incidentally, means Alfred Teves, the engineer who created the ATE company in Germany way back in 1906. He pioneered hydraulic brakes in Europe. For the Ghia, there are 3 different styles of calipers using 3 different shapes of pads. Left to right:

1-pin pad ATE early (1967-71)

2-pin pad ATE (1972-3 year)

U-pin pad Girling (1973-4 year) pad not interchangeable with 1972 ATE.

The twin pistons are 40mm, either ATE or Girling.

The ATE caliper used in 1972 became widely copied (today it is VARGA/TRW) because it used a better pad size than the 67-71 type, and did not require dismounting the caliper to change the pads like the Girling did. Easier for maintenance and racing.

THE REAR DRUM SLAVE CYLINDER UPGRADE

From 1968, the Bug and Ghia had 17.5mm rear slave cylinders. The larger 19.05mm rear slave cylinder from the 1958-1967 models is a direct bolt-on. So is the 22.2mm front slave cylinder from the 1965 or later Bug.

But don't just go out and slap on larger rear cylinders. They do increase rear braking power, but they do not necessarily improve overall braking. They can cause rear wheel lockup if the front brake power is not also increased. Brake proportioning comes into play here. Just read on.

BETTER BRAKE SHOES

Heavy duty or competition linings are available for drum brake shoes. Brake & clutch shops that do their own relining can adhere or rivet upgraded linings to your shoes. Back in the day I used to have a local shop do my shoes and clutches before really good aftermarket parts were available.

Grooved linings are better than solid, as they act somewhat like drilled disks or drums to expel heat and incandescent boundary-layer gasses from red-hot racing brakes.

We currently have Mintex rear shoes on 53. The cheap stock shoes that came on the car when we took delivery of it, even though still good, were replaced in February 2006, after seen constant use since August 2002.

BETTER BRAKE PADS

SCCA Showroom Stock Race, Virginia International Speedway August 1974. The white Opel Ascona with the Maltese Cross over the headlights is driven by Dr. Jim Roberts, who won the race in class and overall. Showroom stock meant just that -- cars off the showroom floor.

A set of stock pads on our Showroom Stock Opel Ascona could be burned totally away in one 10-lap race at Road Atlanta. but that was with Dr. Jim Roberts driving, and he won races. Roberts, who started SCCA racing in 1973, has an impressive record; four SCCA national championships, five HSR championships, and a number of IMSA wins. As a matter of fact, at last count Roberts has 230 wins out of 316 starts, and 51 consecutive first places. Wrenching for Roberts was a good place to start racing.

Back then, with just aggressive street use I could wear through a set of stock front pads in 3000 miles on my 1972 street/autocross/rally Ghia coupe. That is, until I discovered Repco semimetallic pads. They stopped me a great deal quicker, and didn't wear nearly so fast. The Repco's were what we'd call "light track" today, but in 1976 we were glad to get them.

We ran Repco pads on Herbie's front disks, and stock standard shoes on the rear drums. The amazing thing was Herbie's brakes were good. And the rear shoes never wore. Of all Herbie's development problems, brakes were not one of them.

Now, fast forward from 1976 to 2002, and the 1970 Ghia we bought to build into the new 53. The brake hardware is the same as Herbie's, front and rear. But now, brake pad material has greatly advanced.

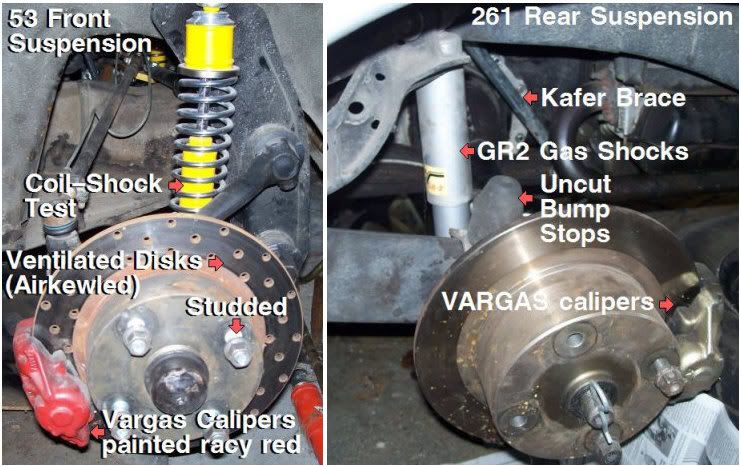

On our Ghia, the original ATE calipers had been replaced by the VARGAS copies. But that wasn't a problem. To begin, I bought a pair of German-made Sebro cross-drilled rotors, something we never had for Herbie.

53's original mission was to do battle in autocrosses, and you don't need much in the way of fancy brake pads for that. We ran stock pads until our first serious track day at the local Talladega Gran Prix in June 2003. Well driven 911's ran 1:12 laps at the TGP then, and in our developmental 1600cc configuration, on street tires, Jim Roberts posted a 1:17.

http://www.youtube.com/watch?v=w0_uceU6EUs&feature=user

When it came Barret's turn to drive (see short video), he ran 1:18's, but after ten minutes of pushing it, the stock pads gave up and the brakes began to seriously fade.

The answer proved to be Porterfield carbon kevlar Pads.

http://www.lpiracing.com/livper/porterfield_1.html

R4 is track only. R4S is for street and light track.

These pads alone fixed the fade problem. No matter the track, from the high-speed Road Atlanta to the tight, brake-intensive Barber Motorsports course, we never experienced fade again. Stock master and slave cylinders, rear drums, shoes, and all.

BRAKE HARDWARE UPGRADES

Lots of companies offer front and rear disk brake upgrades. Airkewld, run by Pete Skiba, has some of the best brake kits.

http://www.airkewld.com/pages/welcome.php

Pete provided our studded and cross-drilled rotors when we replaced the Sebros, and offered his best Bad Brakes kit for our Carrera Panamericana Ghia, but we stuck to VARGA caliper for both 53 and 261. Our decision to stick close to stock was simple. No doubt Pete's brakes are ultimately better, but our brake combo has been working great and we haven't yet reached its limit.

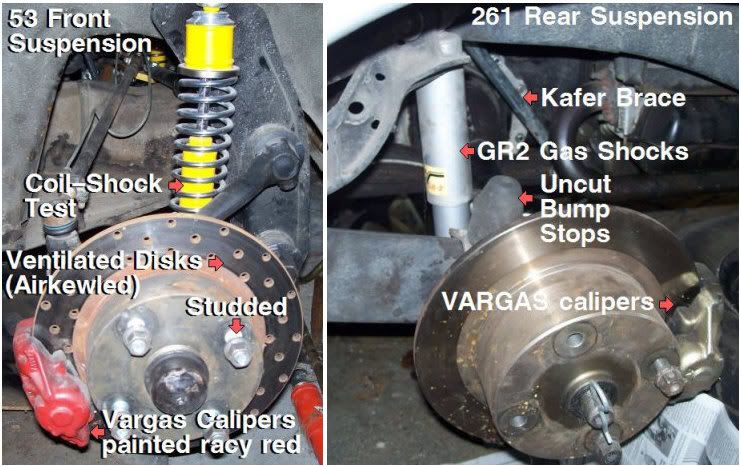

Above: VARGA calipers can be painted racy red if you have the time and a sense of humor. The four-wheel disk brake kit for 261 came from Joe Chirco http://www.chircoestore.com and got our Carrera drivers Barret Camper and Justin Broughton home alive from the 8000 ft. mountain road races.

An important side note is there is a possible complication when installing a disk conversion on a swing axle VW. Remember that on a swing axle, the axle tube is rigid and the brake bracket is bolted to the hub. But, the axle inside the axle tube moves in and out slightly.

Now, your rotor is fixed to the moving axle, and your caliper to the rigidly mounted axle hub!

As you drive, the rotor can shift in and out just enough to pound the pads back (termed knock-back), and when you step on the brakes, you will have to pump them a couple of fast exciting times to make anything happen.

The fix for this is to limit axle travel by shimming the axle bearing "float." Joe Chirco advises this:

The rear axle bearing float needs to be minimized while maintaining sufficient compression on the caliper bracket. There are two ways to accomplish this. One method is to shim the bearing to the correct float. The other method is by machining the bearing retainer cap to size. Some disc kits come with various thickness bearing shims and will function just fine.

By the way, we ran Porterfield R4S pads on 261's front rotors and stock pads on the rear. Worked great.

CROSS-DRILLED ROTORS, DRILLED DRUMS

The holes in disks or drums are not just for cooling, as they might appear. Mainly, they release the gasses created by superheated brake pads and shoes. These gasses act as a lubricant boundary layer between the brake friction material and metal rotor or drum. Our rear drums were drilled by http://www.chtopping.com

Our Herbie never had drilled rear drums.

Our drilled Ghia drums have worked great, and the reason I kept rear drums on the Ghia in the first place was it started competition life as an autocross car, and I wanted an operational handbrake. Drilling the drums were an experiment that worked, and while I do not feel the need to change over to rear disks to improve braking, I intend to eventually change over for easier brake service and inspection at the track. Track cars don't need hand brakes. 261 didn't have them, and it survived Mexico on plastic wheel chocks.

MASTER CYLINDERS

We run a stock Ghia master cylinder, and it works for us. We've used both German and Brazilian, without being able to notice any difference. Of course, remember 53 is a race car, and gets its parts replaced more frequently than a street car, so the durability differences between parts sources does not always affect us in the short term.

The VW dual-circuit master cylinder for disk/drum is 19.05 mm inside diameter. The early 911 m/c was 17mm. Lots of guys have swapped later, larger 911 m/c to VW's because they bolt right up, expecting better braking.

But all a larger inside diameter m/c does is pump more fluid, and (if all else is equal) that means you have to press harder (yes harder) on the brake pedal to get the same amount of braking force. Installing a larger ID master cylinder is justified only when using different calipers with different piston sizes that require more fluid to activate them. That leads us to this:

For four-wheel disk brake conversions do get the special disk/disk m/c offered by some parts houses. We have one on 261. Be aware than unlike drum brakes (and this is a simplification), disk brakes require a little residual pressure to keep the pad just barely in contact with the rotor, and the valving in the m/c provides this.

http://www.mamotorworks.com/acvw-1-0-4690.html

The master cylinder pictured here is from Mid America Motor Works and is 20.6mm ID, to provide for the extra fluid disk calipers require.

BRAKE PROPORTIONING & RESIDUAL VALVES

Traditional to serious racing is brake proportioning, meaning more or less braking effort in the front or rear. Some older setups actually had the brake pedal pushing a see-saw lever that activated two separate master cylinders, one each for the front and rear. By tilting the lever, you got more or less push on one of the two master cylinders, and changed how the car braked.

For street safety, manufacturers learned to provide hydraulic brake proportioning valves (or even mechanical means) to the rear brakes on trucks, vans, etc.

The single, nonadjustable factory valve became more and more common on vehicles of all types. For instance, the 914 came with such a valve. Some drivers complain they can feel the addition of a valve in the brake system because its changes the pedal feedback once it kicks in.

We used an adjustable valve on Herbie, thinking it to be necessary as Herbie was a "real" race car, and ended up removing it. Our valve tended to act erratically, and once even siezed the brakes while going to the grid at Road Atlanta! We've never needed one on 53, or 261.

Residual valves (plumbed into the brake lines) are a little different.

The VW master cylinder is located (but just barely) above the height of the brakes. This is to keep fluid from siphoning back into the master cylinder when the brake pedal is released and making you have to pump the pedal the next time to brake. A residual pressure valve, specifically the 2psi type, fixes this for racing in the mountains.

The 10psi valves are for use in a drum brake system to prevent air from being sucked (via the slave cylinder) into the lines when you release the brake pedal. Common wheel cylinder designs only seal when there is pressure present. Quick release of the brake pedal can cause the seals to relax and allow air to enter the wheel cylinders. 10psi back pressure stops this. The VW disc/drum master cylinders already have internal residual pressure valves.

It's not likely you will need a residual valve but it's possible if you're mixing and matching lots of brake parts from different makers. We don't use residual valves on 53 or 261.

BRAKE FLUID

Brake fluid is made with almost no water in it, because it boils anyway when hot enough, and as it gets older and absorbs moisture, it boils quicker. The water turns to steam inside your brake system and causes vapor pockets and (understatement) erratic braking.

I like Castrol LMA (low moisture avidity) for street use, as it resists absorbing water. For street cars, replacing the brake fluid every two years is highly advisable.

In racing, you will be replacing brake fluid all the time in pre-race bleedings, repairs, parts swaps, etc.

While there is some really great and exotic fluid out there such as ATE Super Blue, we've found that our brake demands on 53 are reasonable enough that NAPA DOT 4 works very well for us.

DOT 4 (Department of Transportation) spec fluid has a minimum dry boiling point of 446 deg. F. contrasted to DOT 3 at 401 deg. F.

There is a silicone-based brake DOT 5 brake fluid with a claimed dry boiling point of 500 deg. F, but be careful. Silicone fluid cannot be mixed with standard brake fluids, so before using silicon fluid, you must completely clean and purge your brake system. Also the silicone fluid seems to many drivers to produce a soft or "spongy" feel to the brake pedal. DOT 5 fluid is seldom seen at the track but is very popular for show cars.

Next TIRES

Preface note. The VW Ghia is such a light car that it's brake demands are only moderate, and most of the extremes in power assisit, brake proportioning, etc., are just not that critical.

BRAKE BASICS ON REAR-ENGINE CARS

The rear-engine car, with more than half its weight in the rear, has a distinct braking advantage. As the weight transfers forward in braking, all four wheels are loaded, making the rear brakes work harder than on a front-engined, front-heavy car.

Even though rear-engined, in hard braking, about 70% of the total VW or Porsche braking effort is still borne by the front brakes!

Front-engined cars obviously overwork their front brakes, which might explain why the Ghia can get by with proportionally smaller brakes all the way around, than say, the Mustang beside it. Smaller, lighter, brakes mean less unsprung weight as well.

THE SWEPT AREA

Also, with the Ghia being a light car to begin with, the factor of "swept-area" versus weight comes into play. The swept area is the friction area on a disk or drum that contacts the brake pad or shoe.

Generally speaking, the larger the swept area, the better the brakes work. Disk brakes have an advantage, as they have a swept area on both sides, whereas drums are considered to have a single area, even through there are two shoes.

VW's have a very good swept area to vehicle weight ratio, in fact, falling even today into the performance brake range. Actually, a 1972 Ghia, box stock, could stop in a shorter distance from 70mph than a 911.

The problem was in constantly repeating the stop, and increasing braking efficiency over 70mph. Which can be done.

STOCK BRAKES? NOT SO BAD

We learned something useful about VW brakes in our 1973 Herbie the Super Bug foray into IMSA B-Sedan Racing in 1976. They are better than expected.

The B-Sedan rules didn't allow for us to change the brakes (except pad or shoe material) so we had to run stock. For the 1973 Super Bug, that meant 2-pin ATE calipers and solid 10.9-inch (277mm) rotors (9.5mm thickness), same as the Ghias had, and rear 9-inch drum brakes, same as on the contemporary Bugs and Ghias.

The AT of ATE, incidentally, means Alfred Teves, the engineer who created the ATE company in Germany way back in 1906. He pioneered hydraulic brakes in Europe. For the Ghia, there are 3 different styles of calipers using 3 different shapes of pads. Left to right:

1-pin pad ATE early (1967-71)

2-pin pad ATE (1972-3 year)

U-pin pad Girling (1973-4 year) pad not interchangeable with 1972 ATE.

The twin pistons are 40mm, either ATE or Girling.

The ATE caliper used in 1972 became widely copied (today it is VARGA/TRW) because it used a better pad size than the 67-71 type, and did not require dismounting the caliper to change the pads like the Girling did. Easier for maintenance and racing.

THE REAR DRUM SLAVE CYLINDER UPGRADE

From 1968, the Bug and Ghia had 17.5mm rear slave cylinders. The larger 19.05mm rear slave cylinder from the 1958-1967 models is a direct bolt-on. So is the 22.2mm front slave cylinder from the 1965 or later Bug.

But don't just go out and slap on larger rear cylinders. They do increase rear braking power, but they do not necessarily improve overall braking. They can cause rear wheel lockup if the front brake power is not also increased. Brake proportioning comes into play here. Just read on.

BETTER BRAKE SHOES

Heavy duty or competition linings are available for drum brake shoes. Brake & clutch shops that do their own relining can adhere or rivet upgraded linings to your shoes. Back in the day I used to have a local shop do my shoes and clutches before really good aftermarket parts were available.

Grooved linings are better than solid, as they act somewhat like drilled disks or drums to expel heat and incandescent boundary-layer gasses from red-hot racing brakes.

We currently have Mintex rear shoes on 53. The cheap stock shoes that came on the car when we took delivery of it, even though still good, were replaced in February 2006, after seen constant use since August 2002.

BETTER BRAKE PADS

SCCA Showroom Stock Race, Virginia International Speedway August 1974. The white Opel Ascona with the Maltese Cross over the headlights is driven by Dr. Jim Roberts, who won the race in class and overall. Showroom stock meant just that -- cars off the showroom floor.

A set of stock pads on our Showroom Stock Opel Ascona could be burned totally away in one 10-lap race at Road Atlanta. but that was with Dr. Jim Roberts driving, and he won races. Roberts, who started SCCA racing in 1973, has an impressive record; four SCCA national championships, five HSR championships, and a number of IMSA wins. As a matter of fact, at last count Roberts has 230 wins out of 316 starts, and 51 consecutive first places. Wrenching for Roberts was a good place to start racing.

Back then, with just aggressive street use I could wear through a set of stock front pads in 3000 miles on my 1972 street/autocross/rally Ghia coupe. That is, until I discovered Repco semimetallic pads. They stopped me a great deal quicker, and didn't wear nearly so fast. The Repco's were what we'd call "light track" today, but in 1976 we were glad to get them.

We ran Repco pads on Herbie's front disks, and stock standard shoes on the rear drums. The amazing thing was Herbie's brakes were good. And the rear shoes never wore. Of all Herbie's development problems, brakes were not one of them.

Now, fast forward from 1976 to 2002, and the 1970 Ghia we bought to build into the new 53. The brake hardware is the same as Herbie's, front and rear. But now, brake pad material has greatly advanced.

On our Ghia, the original ATE calipers had been replaced by the VARGAS copies. But that wasn't a problem. To begin, I bought a pair of German-made Sebro cross-drilled rotors, something we never had for Herbie.

53's original mission was to do battle in autocrosses, and you don't need much in the way of fancy brake pads for that. We ran stock pads until our first serious track day at the local Talladega Gran Prix in June 2003. Well driven 911's ran 1:12 laps at the TGP then, and in our developmental 1600cc configuration, on street tires, Jim Roberts posted a 1:17.

http://www.youtube.com/watch?v=w0_uceU6EUs&feature=user

When it came Barret's turn to drive (see short video), he ran 1:18's, but after ten minutes of pushing it, the stock pads gave up and the brakes began to seriously fade.

The answer proved to be Porterfield carbon kevlar Pads.

http://www.lpiracing.com/livper/porterfield_1.html

R4 is track only. R4S is for street and light track.

These pads alone fixed the fade problem. No matter the track, from the high-speed Road Atlanta to the tight, brake-intensive Barber Motorsports course, we never experienced fade again. Stock master and slave cylinders, rear drums, shoes, and all.

BRAKE HARDWARE UPGRADES

Lots of companies offer front and rear disk brake upgrades. Airkewld, run by Pete Skiba, has some of the best brake kits.

http://www.airkewld.com/pages/welcome.php

Pete provided our studded and cross-drilled rotors when we replaced the Sebros, and offered his best Bad Brakes kit for our Carrera Panamericana Ghia, but we stuck to VARGA caliper for both 53 and 261. Our decision to stick close to stock was simple. No doubt Pete's brakes are ultimately better, but our brake combo has been working great and we haven't yet reached its limit.

Above: VARGA calipers can be painted racy red if you have the time and a sense of humor. The four-wheel disk brake kit for 261 came from Joe Chirco http://www.chircoestore.com and got our Carrera drivers Barret Camper and Justin Broughton home alive from the 8000 ft. mountain road races.

An important side note is there is a possible complication when installing a disk conversion on a swing axle VW. Remember that on a swing axle, the axle tube is rigid and the brake bracket is bolted to the hub. But, the axle inside the axle tube moves in and out slightly.

Now, your rotor is fixed to the moving axle, and your caliper to the rigidly mounted axle hub!

As you drive, the rotor can shift in and out just enough to pound the pads back (termed knock-back), and when you step on the brakes, you will have to pump them a couple of fast exciting times to make anything happen.

The fix for this is to limit axle travel by shimming the axle bearing "float." Joe Chirco advises this:

The rear axle bearing float needs to be minimized while maintaining sufficient compression on the caliper bracket. There are two ways to accomplish this. One method is to shim the bearing to the correct float. The other method is by machining the bearing retainer cap to size. Some disc kits come with various thickness bearing shims and will function just fine.

By the way, we ran Porterfield R4S pads on 261's front rotors and stock pads on the rear. Worked great.

CROSS-DRILLED ROTORS, DRILLED DRUMS

The holes in disks or drums are not just for cooling, as they might appear. Mainly, they release the gasses created by superheated brake pads and shoes. These gasses act as a lubricant boundary layer between the brake friction material and metal rotor or drum. Our rear drums were drilled by http://www.chtopping.com

Our Herbie never had drilled rear drums.

Our drilled Ghia drums have worked great, and the reason I kept rear drums on the Ghia in the first place was it started competition life as an autocross car, and I wanted an operational handbrake. Drilling the drums were an experiment that worked, and while I do not feel the need to change over to rear disks to improve braking, I intend to eventually change over for easier brake service and inspection at the track. Track cars don't need hand brakes. 261 didn't have them, and it survived Mexico on plastic wheel chocks.

MASTER CYLINDERS

We run a stock Ghia master cylinder, and it works for us. We've used both German and Brazilian, without being able to notice any difference. Of course, remember 53 is a race car, and gets its parts replaced more frequently than a street car, so the durability differences between parts sources does not always affect us in the short term.

The VW dual-circuit master cylinder for disk/drum is 19.05 mm inside diameter. The early 911 m/c was 17mm. Lots of guys have swapped later, larger 911 m/c to VW's because they bolt right up, expecting better braking.

But all a larger inside diameter m/c does is pump more fluid, and (if all else is equal) that means you have to press harder (yes harder) on the brake pedal to get the same amount of braking force. Installing a larger ID master cylinder is justified only when using different calipers with different piston sizes that require more fluid to activate them. That leads us to this:

For four-wheel disk brake conversions do get the special disk/disk m/c offered by some parts houses. We have one on 261. Be aware than unlike drum brakes (and this is a simplification), disk brakes require a little residual pressure to keep the pad just barely in contact with the rotor, and the valving in the m/c provides this.

http://www.mamotorworks.com/acvw-1-0-4690.html

The master cylinder pictured here is from Mid America Motor Works and is 20.6mm ID, to provide for the extra fluid disk calipers require.

BRAKE PROPORTIONING & RESIDUAL VALVES

Traditional to serious racing is brake proportioning, meaning more or less braking effort in the front or rear. Some older setups actually had the brake pedal pushing a see-saw lever that activated two separate master cylinders, one each for the front and rear. By tilting the lever, you got more or less push on one of the two master cylinders, and changed how the car braked.

For street safety, manufacturers learned to provide hydraulic brake proportioning valves (or even mechanical means) to the rear brakes on trucks, vans, etc.

The single, nonadjustable factory valve became more and more common on vehicles of all types. For instance, the 914 came with such a valve. Some drivers complain they can feel the addition of a valve in the brake system because its changes the pedal feedback once it kicks in.

We used an adjustable valve on Herbie, thinking it to be necessary as Herbie was a "real" race car, and ended up removing it. Our valve tended to act erratically, and once even siezed the brakes while going to the grid at Road Atlanta! We've never needed one on 53, or 261.

Residual valves (plumbed into the brake lines) are a little different.

The VW master cylinder is located (but just barely) above the height of the brakes. This is to keep fluid from siphoning back into the master cylinder when the brake pedal is released and making you have to pump the pedal the next time to brake. A residual pressure valve, specifically the 2psi type, fixes this for racing in the mountains.

The 10psi valves are for use in a drum brake system to prevent air from being sucked (via the slave cylinder) into the lines when you release the brake pedal. Common wheel cylinder designs only seal when there is pressure present. Quick release of the brake pedal can cause the seals to relax and allow air to enter the wheel cylinders. 10psi back pressure stops this. The VW disc/drum master cylinders already have internal residual pressure valves.

It's not likely you will need a residual valve but it's possible if you're mixing and matching lots of brake parts from different makers. We don't use residual valves on 53 or 261.

BRAKE FLUID

Brake fluid is made with almost no water in it, because it boils anyway when hot enough, and as it gets older and absorbs moisture, it boils quicker. The water turns to steam inside your brake system and causes vapor pockets and (understatement) erratic braking.

I like Castrol LMA (low moisture avidity) for street use, as it resists absorbing water. For street cars, replacing the brake fluid every two years is highly advisable.

In racing, you will be replacing brake fluid all the time in pre-race bleedings, repairs, parts swaps, etc.

While there is some really great and exotic fluid out there such as ATE Super Blue, we've found that our brake demands on 53 are reasonable enough that NAPA DOT 4 works very well for us.

DOT 4 (Department of Transportation) spec fluid has a minimum dry boiling point of 446 deg. F. contrasted to DOT 3 at 401 deg. F.

There is a silicone-based brake DOT 5 brake fluid with a claimed dry boiling point of 500 deg. F, but be careful. Silicone fluid cannot be mixed with standard brake fluids, so before using silicon fluid, you must completely clean and purge your brake system. Also the silicone fluid seems to many drivers to produce a soft or "spongy" feel to the brake pedal. DOT 5 fluid is seldom seen at the track but is very popular for show cars.

Next TIRES

Last edited by FJCamper on Thu Dec 03, 2009 2:04 pm, edited 2 times in total.

-

karol

- Posts: 38

- Joined: Fri Jan 02, 2004 5:11 am

Re: Ghia Road Course Setup

excellent thread! keep going.

Sticky maybe?

Sticky maybe?

-

Mabbo

- Posts: 453

- Joined: Wed May 14, 2003 4:48 am

Re: Ghia Road Course Setup

Well dude, that was a great post on brakes  Thanks for sharing your knowledge/experience

Thanks for sharing your knowledge/experience

I currently have standard VW front discs and ATE calipers, with a rear EMPI disc kit on my Bug. I have been considering upgrading to vented front discs and 4 piston front and rear calipers for some time. I considered the Porsche 944 route as many people seem to do, but Im not keen on converting my swing axle bug to IRS and ideally wanted to keep 4x130 wheels.

I was considering using the vented Kerscher style one piece disc at the front with a Wilwood 4 piston caliper, or maybe the bolt on Tarox 6 piston caliper, but assume that is complete overkill? At the rear I have been thinking about keeping the solid rotor from the Empi kit and changing the caliper to a 4 piston Wilwood handbrake caliper, but I am worried that knock-back with a 4 piston caliper would be worse than with a single piston sliding caliper like on the Empi kit, and the Wilwood 4 piston handbrake caliper dont have any dust seals.

What are your opinions on the above changes? I see Airkewld do front disc kits with Wilwood calipers, but they use solid rotors. I like the idea of vented rotors as I intend to do some track action now and again.

Im not sure how my idea would compare to what I have now, a Porsche 944 swap or even a standard setup.

Thanks again,

Mabbo

I currently have standard VW front discs and ATE calipers, with a rear EMPI disc kit on my Bug. I have been considering upgrading to vented front discs and 4 piston front and rear calipers for some time. I considered the Porsche 944 route as many people seem to do, but Im not keen on converting my swing axle bug to IRS and ideally wanted to keep 4x130 wheels.

I was considering using the vented Kerscher style one piece disc at the front with a Wilwood 4 piston caliper, or maybe the bolt on Tarox 6 piston caliper, but assume that is complete overkill? At the rear I have been thinking about keeping the solid rotor from the Empi kit and changing the caliper to a 4 piston Wilwood handbrake caliper, but I am worried that knock-back with a 4 piston caliper would be worse than with a single piston sliding caliper like on the Empi kit, and the Wilwood 4 piston handbrake caliper dont have any dust seals.

What are your opinions on the above changes? I see Airkewld do front disc kits with Wilwood calipers, but they use solid rotors. I like the idea of vented rotors as I intend to do some track action now and again.

Im not sure how my idea would compare to what I have now, a Porsche 944 swap or even a standard setup.

Thanks again,

Mabbo

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Ghia Road Course Setup

Hi Mabbo,

Nothing wrong with a fancy set of brakes if that's what you want. Just make sure they are proportioned right, and get used to the different response. Overkill brakes and wide tires make for lockup under conditions where you're not expecting it. Sort of like the first time someone drives a car with power brakes and keeps trying to throw themselves through the windshield.

I agree vented rotors are best at the limit -- but not as the rule for street use. We ran unvented rotors on our Carrera Ghia to keep the most metal heatsink mass and contact area for the mountain stages of the racing.

In track racing, you get the brakes hot and keep them hot. You need to vent out the burning gasses. On the street, you run hot and cold.

That said, vented rotors look more serious, and they do dispell water better. Street use means driving in the rain.

Airkewld is a great place to get your custom brakes. Like I said in my post, that's who we went to for 53's rotors and studding.

FJC

Nothing wrong with a fancy set of brakes if that's what you want. Just make sure they are proportioned right, and get used to the different response. Overkill brakes and wide tires make for lockup under conditions where you're not expecting it. Sort of like the first time someone drives a car with power brakes and keeps trying to throw themselves through the windshield.

I agree vented rotors are best at the limit -- but not as the rule for street use. We ran unvented rotors on our Carrera Ghia to keep the most metal heatsink mass and contact area for the mountain stages of the racing.

In track racing, you get the brakes hot and keep them hot. You need to vent out the burning gasses. On the street, you run hot and cold.

That said, vented rotors look more serious, and they do dispell water better. Street use means driving in the rain.

Airkewld is a great place to get your custom brakes. Like I said in my post, that's who we went to for 53's rotors and studding.

FJC

- FJCamper

- Moderator

- Posts: 2910

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Ghia Road Course Setup

No one single item changes how a VW feels and handles more than tires.

STREET TIRES vs RACE TIRES WARNING

DOT (Department of Transportation) approved tires are the only "street legal tires" in the US. Racing tires may or may not be DOT approved, but as a rule are not good for street use. Racing tires are generally weaker in construction and tend to lose air faster than street tires, and racing rubber compounds usually have to be at the right temperature to work.

BIAS-PLY vs RADIAL TIRES

Let's start with the basics. Tires come in two types, bias-ply and radials. The difference is how the layers of inner carcass material are wrapped. The bias-ply (sometimes called a cross-ply) tire is rare these days and mainly made by specialty tire companies for vintage show or race cars, such as the Goodyear Blue Streak or Dunlop bias racing tires sold by http://www.sascosports.com or vintage street tires from http://www.cokertire.com

Michelin invented the radial (steel outer belt and all as the famous Michelin X) in 1946 for the front wheel drive Citroen. Radial tires (even without the steel belt) have less rolling resistance, put down a larger tread patch to the pavement, and last longer than bias-ply tires.

It took many years for the radial tire to take over. It required different equipment to make radials, and the big US tire companies held out as long as possible, fending off the radial until the 1970's, offering "belted bias-ply" tires in the 60's to confuse the buying public. A belt is the outermost layer of carcass material under the tread. Belts were made of fiberglass or nylon, and even woven steel mesh. "Steel Belted" sounds like Steel Belted [radial] in an ad. The Firestone "wide oval" tire (introduced in 1967) and the Goodyear Polyglas tire were belted-bias designs.

US tire and auto makers had spun publicity tales that radials were rough riding and possibly even dangerous, to excuse why they didn't offer them.

When General Motors finally began to offer radials, they had to badge the cars (beginning with Pontiac in 1974) as having special "Radial Tuned Suspensions" that compensated for the fictional harsh ride story their own PR people had created.

SWING AXLES & RADIALS = DEATH TRAP?

The anti-radial propaganda was taken seriously by some VW and Porsche fans. The better traction and more sudden response of the radial caused (untrue) stories that radials were dangerous on the Porsche-designed suspension, which needed bias-ply tires with their more predictable breakaway characteristics.

It is true that bias-ply tires tend to slide where radials tend to grip, but Porsche itself put the "unsafe" worry to rest when it began to issue radials on the 356's as new OEM equipment instead of the usual standard-issue Continental bias-ply tires.

THE RACING RADIAL

For years, the radial tire was considered great for family or sports car use, but not for racing. Racers still used the familiar and old reliable bias-ply constructions. Suspension tuning was even slanted toward bias-ply sliding!

The radial was considered too heavy a construction for high speed work. Bias racing construction had been refined to being light and durable, and did not hold heat like radials. For instance, Michelin's first high performance radial, the XAS (asymmetrical tread) released in 1965 required an inner tube where bias-ply design had long since moved on to tubeless. Tubes hold heat and create internal friction that make more heat.

But radial manufacturers wanted to prove radial designs could race, and by the mid-1970's, BF Goodrich was sponsoring the Radial Challenge for road racing. A BFG Radial T/A with half its tread depth shaved off (to reduce weight and shed heat) was a formidable racing tire in that IMSA series. By 1977, Michelin had introduced racing radials to Formula 1.

The point here is the radial tire (almost any radial tire) you drive on today is better than the best racing rubber you could once buy.

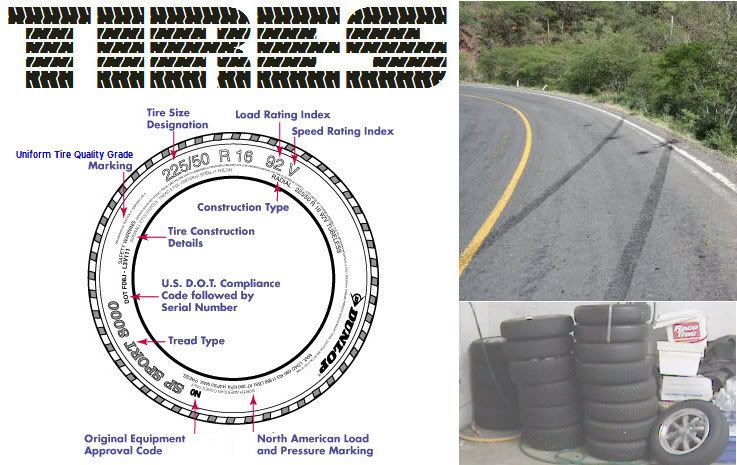

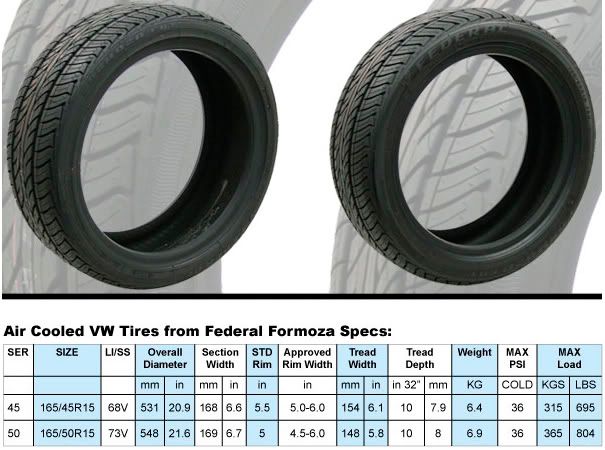

45 and 50 series Federal Formoza VW tires sold by http://www.cip1.com These tires are very low profile, just 21.6 inches diameter for the 50 series, where a standard 165x15 tire is typically 25 inches diameter. Running the lower profile is a dramatic change in overall gearing, with the effect of having a much lower (less top speed) final drive gear -- not to mention lowering your ride height by 1.7 inches.

SLIP ANGLES and LOW-PROFILE DESIGNS

Tires have "aspect ratios" or series (the height of the sidewall relative to tire width) that greatly affect how the tire responds. The classic old bias-ply tire VW and Porsche 356 came with was a 70-series tire. Very low aspect ratio racing tires go down to 25-series. A 50 to 45-series tire is considered low today for a street tire.

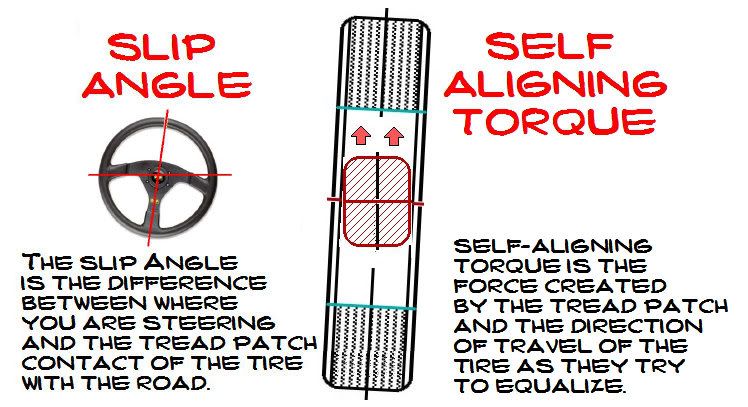

Good things about low profile tires is with less sidewall to flex, the tread patch follows the main carcass of the tire more accurately, and the slip angle is reduced. This makes more responsive handling. Also, a low profile tire tends to have a larger tread patch even if mounted on the same wheel as a previous high profile tire.

Lots of slip means steering response is slow, as the tread patch and tire carcass get in line with each other. Self-aligning torque is the force that accomplishes this.

A bad thing about low profile tires is the larger tread patch (given that the vehicle weight is the same) tends to hydroplane at lower speeds. Also, higher profile tires allow more cushioning on bumps and act as part of the suspension. A pothole that a higher profile tire might bounce over can burst a low profile tire.

A true "slick."

RACING SLICKS vs RAIN TIRES (and why do tires squeal?)

The tread pattern on a tire is intended to disperse water. This is the Hoosier Speedster racing radial currently used by vintage racers.

Sometime in the 1950's, the slick (no tread pattern) racing tire was developed. The first slicks were for drag racing, and by the 1960's were being used in road racing.

Slicks provide more traction because they put more rubber on the ground compared to the same tire with a tread pattern. The downside is slick tires can't be used in the rain, which is why worn street tires (usually described as bald) are dangerous.

Tires with tread squeal when cornering because the tread blocks rub together. Slicks don't squeal.

TIRE WEAR & TIRE COMPOUNDS

Racing-only tires require that they get hot before the rubber compound begins to get stick and work. You may have noticed the drivers weaving back and forth to scrub their tires on the pace laps.

Street tires have to work cold, wet, and ten feet out of the driveway. They are marvels of compromise.

The rate of tire wear (racing or street) is decided by the hardness of the rubber compound. Actually, tires haven't been made out of real rubber since 1940, when BF Goodrich introduced the synthetic rubber tire.

Racing tires come in hard, medium, and soft compounds. As a rule, the softer the compound, the better the tire handles but the faster it wears. Hard compounds are for heavier racing cars, medium is for compromises, and soft is for the best short-race handling.

Street tires are usually made of a hard compound because a long service life is more important than maximum handling potential.

Avon racing radials stacked in our paddock at Roebling Road. Very simple tread pattern.

On our 53 (a 1970 Ghia) and 261 (a 1965 Ghia) we run medium and soft Avon racing radial compounds (CR6ZZ 175/70/R15). 53 uses soft for common track, and 261 ran medium for the Carrera Panamericana. The medium-compound Avons withstood 2000+ miles and still have tread.

Autocrossers should use the softest compound available. Soft also works for short, tight road courses. Longer, faster, courses need medium or even hard compounds.

You can tell how soft -- or how hot -- a racing tire is by the amount of gravel or pebbles sticking in the rubber. Listen to the cars as they come in from a session, you'll hear the pebbles being flung off the tires into the fender wells.

SUSPENSION TUNING via TIRE PRESSURE

There are many variables in tire types, but in general a good starting point for a VW road racer's tire pressure is 24psi front and 28psi rear.

By comparison, VW specified 18psi front and 29psi rear for normal street use with the standard-issue 6.00x15 Continental bias-ply tires that came new on 1971-74 models with their 4.5 J x 15 wheels. Slicks normally take less pressure, racing radials take about the same as bias-ply.

To get a quick read on how well your suspension is set up for a particular course, just check your tire pressures after an autocross run or practice lap. The more the tire pressure has increased, the harder the tire is working.

Ideally, you would like to see even increases in pressure side to side and front to rear. But this is rare.

More likely it'll be like this example. The front tire pressure (TP) started at 24psi cold, and after one autocross run the car comes in with 30psi. The rear began at 28psi and comes in at 30psi.

This means the front end is working very hard indeed. The fronts went up 6psi, the rears just 2psi.

In this case, there is too much understeer. With adjustable sway bars, the fix is to tighten up the rear sway bar or loosen the front sway bar. Without adjustable bars, you could boost the front TP by 2psi and run again, and see if the TP increase is the same.

More pressure up increases adhesion on any one tire. Fight understeer by raising front pressures. Fight oversteer by raising rear pressures. Go up or down by 2psi increments when fighting oversteer or understeer.

You can overpressurize, of course. Usually, go no more than six to eight psi over what would be your normal street pressure.

If one tire at either end is hotter (more pressure gain) than it's same-axle mate, that means there are more corners that load that one side vs. the other. Unless you are on a circle track, not much you can do about it.

NITROGEN INFLATION

Air expands when hot, and changes both the pressure and diameter of the affected tire, all of which changes handling. Nitrogen greatly reduces this, but not entirely.