The easiest way I have found to test the ignition system is to use a test light while the coil is still on the car. In order for the ignition coil to create a spark it only needs two voltage signals.

These tests apply whether you have a point type ignition system or electronic ignition.

One of these inputs are at Terminal # 15 of the coil must have constant +12V when the key is on, cranking, or running.

The other input side of the coil Terminal # 1 must have a "pulsing" ground when the engine is turning over.

If you put the test light across the two primary input terminals of the coil, and have someone crank the engine, the test light will flash if the points are triggering the coil.

If the light stays ON constantly, or stays OFF constantly during cranking, then the problem is BEFORE the coil.

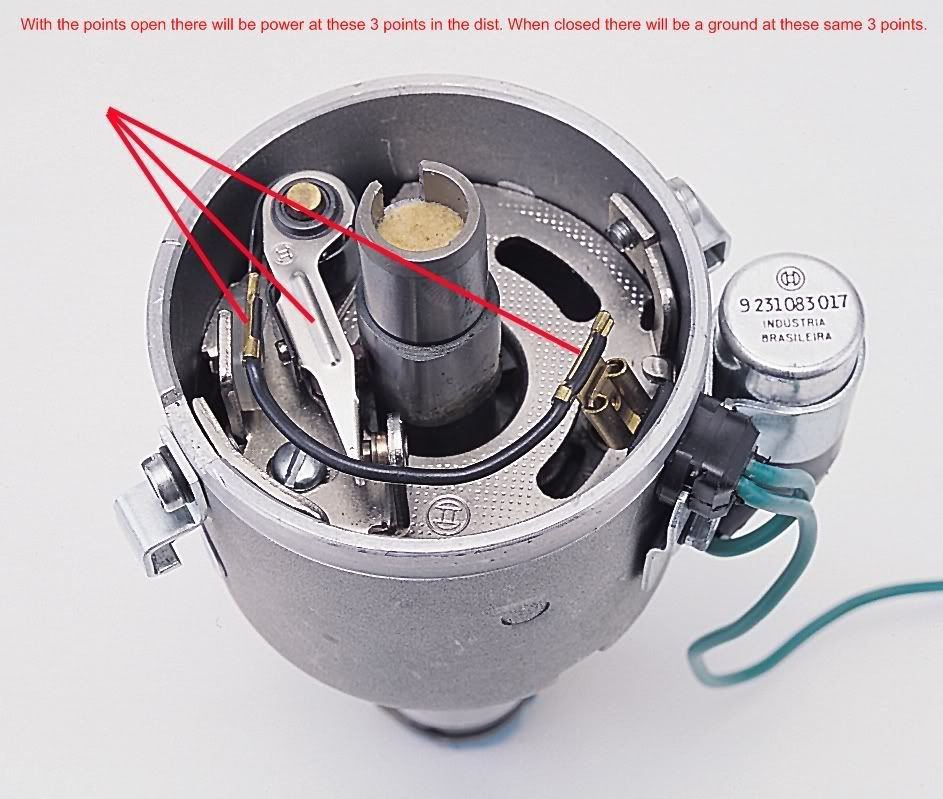

If the test light doesn't blink, and you have verified that terminal # 15 has power, then the coil at not at fault. The test light can be hooked to either power or ground to test the trigger at terminal # 1 it doesn't matter. The way it works is that the points switch from power to ground as the distributor rotates as the points open and close. So you can use the test light to see if you have the switching of the points from power to ground by either hooking the test light to power or ground, and crank the engine over.

If you confirm you have the correct inputs to the coil (test light flashes), but are not getting spark out of the coil, then the coil is bad. It is just that simple. No more tests are needed the coil only needs these two inputs. The coil doesn't even require a ground to produce spark.

Now if you have spark at the coil and no spark at the plugs you will need to look at the wires, cap, and rotor.

Laying the spark plug against the block and turning the engine over will not adequately test ignition coil output. The ignition coil will only generate enough output to jump the gap of the plug. When under compression, the plug requires twice the voltage to fire. This check is not an accurate test of the coil and can be misleading. So you will need to at least double the gap on the plug to check the out put of the coil, to be in the ball park. In the video the spark is jumping close to half an inch from the coil to ground

These are the check points to test your ignition system for power when the points are open. If you close the points you will not have power at these check points. If your tests show different results replace the points and the condenser. This is the same test that can be done at terminal #1 of the coil. I start at the coil when diagnosing no spark. Test lamp on terminal # 15 and terminal # 1. If the test lamp blinks we have verified we have power at terminal # 15 and have a set points, and condenser that will trigger the coil at terminal #1.

Now if you have no spark out of the coil without the test light then the coil is defective Note that you may or may not have spark if you are using the test light and checking the spark at the same time. This is because of the resistance in the test light.

Ok now let’s look at the spark path between the coil and the plugs. The coil wire goes into the distributor on the inside of the cap is a little button that rides on the rotor button. This button can wear and results can be weak or no spark to the plugs, cracks in the cap can cause the same problems. Next in the spark path is the rotor button. It is possible for the spark to burn a pin hole in the rotor and the spark to use the distributor shaft for ground. It is very unlikely you will ever see this problem with ignition point type system.

That brings us to the ignition wires and plugs. This is where most miss-fires can be found. A cracked distributor cap will also cause miss-fires. Plugs, caps and wires cause miss-fires as well as lean mixtures. We can rule out the ignition parts as being a cause of miss-fire by swapping the wires and plugs one at a time between a cylinder that is making power and one that is dead. This usually pin points the problem, but not always. One method to check your ignition wires is to spray water on them. Another way is to ground a test light and hold it to the ignition wire not the tip but with the shank above the tip. Try it on both sides of each ignition wire. When the engine stumbles or miss-fires you have found the problem either by a visual inspection or hands on.

Short Video on Spark

Here is a simple test you can do to check spark out of the coil using one wire if you have points.

As you can see in the diagram above all ignition systems have a trigger for the coil.

There are many configurations of ignition systems but all operate on the same principle. They all create a low energy field and collapse it into a high energy coil and transfer’s the electrical energy into the secondary ignition system. All systems are triggered by the primary ignition system, this system varies depending on manufacturer but all operate on the same principle, and all use some kind of low voltage trigger system. This low voltage is amplified and then transferred to the primary side of the ignition coil. This signal is only present when the key is on and the engine is rotating.

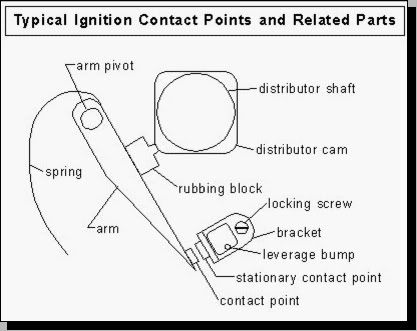

The VW distributor cam rotates in time with the engine, making one complete revolution for every two revolutions of the engine. As it rotates, the cam pushes the points open and closed. Every time the points open, the flow of current is interrupted through the ignition coil, thereby collapsing the magnetic field and releasing a high voltage surge through the secondary coil windings. This voltage surge goes out the of the coil secondary terminal and through the coil wire.

Now, that we have the voltage necessary to fire the spark plug, but it still has to get it to the correct cylinder. The coil wire goes from the coil directly to the center of the distributor cap. Under the cap is a rotor that is mounted on top of the rotating shaft. The rotor has a metal strip on the top that is in constant contact with the center terminal of the distributor cap. It receives the high voltage surge from the coil wire and sends it to the other end of the rotor which rotates past each spark plug terminal inside the cap. As the rotor turns on the shaft, it sends the voltage to the correct spark plug wire, and then sends it to the spark plug. This secondary voltage enters the spark plug at the terminal at the top and travels down the core until it reaches the tip. It then jumps across the gap at the tip of the spark plug to ground.

Here is a short video notice the blinking LED on the top of the coil. It is connected between terminals # 15 & #1 you can see the spark plugs sparking in the video.

Ok in this video you can see the spark out of the coil wire when I touch the test light to terminal #1 and have the other end hooked to terminal # 15 the spark goes away because of the resistance of the test lamp. This is actually with the Accufire electronic ignition but points work the same way.

Here is a video demonstrating the effects of test lights and LED lights looking at the secondary spark when hooked between the primary terminals of the coil. In parts of the video you can't see the spark but you can hear it.