2838 type 4 buildup

-

User Name

- Posts: 48

- Joined: Wed Apr 29, 2009 3:34 pm

WOW that's a lot ofwork you have put in there

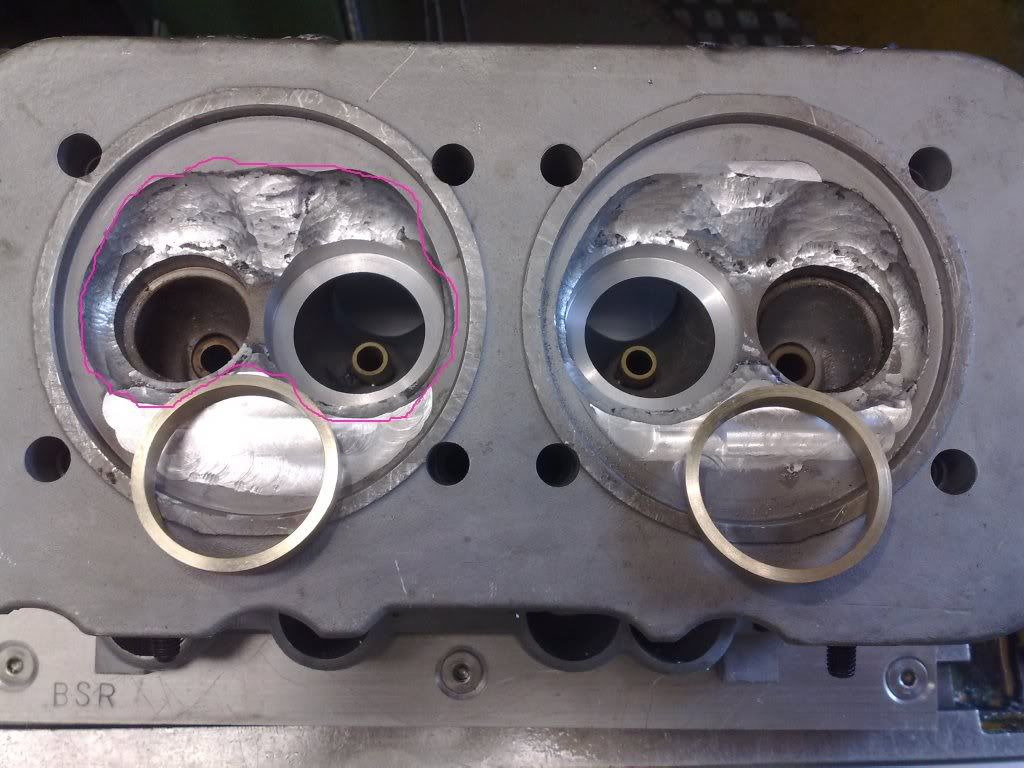

this last picture of the combustion chambers to the previous one, you have taken more metal out, was that going to give you too high a compresion ratio

the picture showing the valve seats, are you making the valves aswell

very interesting stuff, very looking forward to seeing it running

this last picture of the combustion chambers to the previous one, you have taken more metal out, was that going to give you too high a compresion ratio

the picture showing the valve seats, are you making the valves aswell

very interesting stuff, very looking forward to seeing it running

-

Getbackontrack

- Posts: 241

- Joined: Thu Oct 27, 2005 2:08 am

-

Getbackontrack

- Posts: 241

- Joined: Thu Oct 27, 2005 2:08 am

- Type 4 Unleashed

- Moderator

- Posts: 2202

- Joined: Tue Nov 08, 2005 10:43 pm

User Name wrote:it's probably just do to the pictures being at different angles, it's just that the combustion chambers look different sizes

Jakob

You do know, you need to install all the seats at the same ? And that means you've also made a tool to install the exh seats ?

Richard

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

-

Getbackontrack

- Posts: 241

- Joined: Thu Oct 27, 2005 2:08 am

Why would I need to install ALL the seats at the same time Richard?

The way I see it. When you have two holes so close to each other, there is a big chance of deforming the roundness of one of the holes when you punch in a seat with a lot of force in the other hole? Besides there is not much material left between the new seats (when both is bored to the oversize) so there will also be a chance that this area will crack when you punch them in.

And yes, I know I need another tool for the exhaust seats.

Regards, Jakob

The way I see it. When you have two holes so close to each other, there is a big chance of deforming the roundness of one of the holes when you punch in a seat with a lot of force in the other hole? Besides there is not much material left between the new seats (when both is bored to the oversize) so there will also be a chance that this area will crack when you punch them in.

And yes, I know I need another tool for the exhaust seats.

Regards, Jakob

- Type 4 Unleashed

- Moderator

- Posts: 2202

- Joined: Tue Nov 08, 2005 10:43 pm

Getbackontrack wrote:Why would I need to install ALL the seats at the same time Richard?

The way I see it. When you have two holes so close to each other, there is a big chance of deforming the roundness of one of the holes when you punch in a seat with a lot of force in the other hole? Besides there is not much material left between the new seats (when both is bored to the oversize) so there will also be a chance that this area will crack when you punch them in.

And yes, I know I need another tool for the exhaust seats.

Regards, Jakob

Why would I need to install ALL the seats at the same time Richard?

The way I see it. When you have two holes so close to each other, there is a big chance of deforming the roundness of one of the holes when you punch in a seat with a lot of force in the other hole? Besides there is not much material left between the new seats (when both is bored to the oversize) so there will also be a chance that this area will crack when you punch them in.

Because, you only want to heat the heads up once when you install the seats. You don't want to have to let them cool after just installing the Int seats then reheat the heads again later to install the Exh seats, the Int's are the critical install, and could very well be an issue if they are reheated again to install the Exh. You have to remember the Int's are the seats that fall out, and thats due to the constant heating and cooling of the seats, the chamber combustion heats the head and the seats, and the cool Int charge cools the seat each and every cycle, and heating the heads to the temps needed to install the seats are far more than they would see in normal engine temps.

The two materials are different, the seats will expand at a different rate than the heads will when you re-heat to install the Exh and could very well distort then ?.

And yes I know you know you need another tool for the Exh sears, and I know you hadn't made one yet to install the seats, cause you were probably gonna wait till after you installed the Int's, and this was an assumption since you hadn't posted a pic of the Exh tool and you hadn't cut the head for the Exh seat...And yes, I know I need another tool for the exhaust seats.

I have watched this process a few times, and it is a very fast paced procedure, Bam Bam, the Int's are installed, then Bam Bam the Exh are done, the head is then set aside to cool naturally, then the next head is done.

These are suggestions, take them or leave them, but maybe they will save you some grief in the end...

Richard

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

EMW

“Have you ever noticed how some people never

have the money to do it right, but can always

find the money to do it twice ?”

-

Getbackontrack

- Posts: 241

- Joined: Thu Oct 27, 2005 2:08 am

Guess you have a point there Richard. I had been thinkin about the "sideeffect" of reheating the head a second time for the exhaust seat. But My plan was only to heat the head to about 100 degrees celcius. And the heads will see that temp all the time, so couldnt see the problem in doing it twice.. What tempreture would you think would be needed to do the job?

-

Getbackontrack

- Posts: 241

- Joined: Thu Oct 27, 2005 2:08 am

So, got the two exhaust holes cut up for the new valves aswell, I have now installed them all in the head. I also made two dummy valves to put in the chambers while I grind them.

Regards, Jakob

Regards, Jakob

Last edited by Getbackontrack on Thu Sep 03, 2009 10:47 am, edited 1 time in total.