911 heads

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hello, I got cams done from not less than three sources and all in Sweden.

I have written it before, the first two failed me with run down cams, the last one seems ok.

I do intend to send them for DLC coating in any case. Just got to sort out a good supplier that takes my simple order of two cams.

In any case, why do you not check out the nice version of using original cam like the UK guys did?

Dont you love technology? I am sitting in a tent in the middle of alligator country, right in Everglades after midnight and writing this?

Frallan

I have written it before, the first two failed me with run down cams, the last one seems ok.

I do intend to send them for DLC coating in any case. Just got to sort out a good supplier that takes my simple order of two cams.

In any case, why do you not check out the nice version of using original cam like the UK guys did?

Dont you love technology? I am sitting in a tent in the middle of alligator country, right in Everglades after midnight and writing this?

Frallan

-

M-Owen

- Posts: 64

- Joined: Wed Dec 05, 2007 5:23 pm

A tent? what are you doing there of all places, my brother lives in Miami and he can't stay out of the everglades himself. I have yet to understand the attraction.

I am having material selection problems since I have to make new cams due to the configuration I am attempting. I want to get it close to right before coating, by the way there is a company in my neighborhood that does coating and all types of metal treatment I will send the info when I get home tonight.

I am having material selection problems since I have to make new cams due to the configuration I am attempting. I want to get it close to right before coating, by the way there is a company in my neighborhood that does coating and all types of metal treatment I will send the info when I get home tonight.

- Piledriver

- Moderator

- Posts: 22760

- Joined: Sat Feb 16, 2002 12:01 am

Have you considered ion or even gas nitriding?

More than one cam manufacturer is using it with excellent results, and it probably costs about the same.

Nitriding provides considerable control as to hardness level and depth: DLC has little or no hardness lattitude, and absolutely no depth to speak of.

Once it wears through that very,very thin layer of carbon, it's over.

More than one cam manufacturer is using it with excellent results, and it probably costs about the same.

Nitriding provides considerable control as to hardness level and depth: DLC has little or no hardness lattitude, and absolutely no depth to speak of.

Once it wears through that very,very thin layer of carbon, it's over.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

Hello Piledriver,

My first set of cams failed due to lack of good control process in the flame hardening.

Second set were improved SIS 0125 steel that was induction hardened.

It worked well until I ran the car through a winter in Italy and started diluting the oil with a very rich fuel setting in combination with high ring blowby.

If not fixing the problem nor changing oil on frequent basis, it will kill the frictional properties....I asked for it.

Anyway, DLC coating does not "wear off" as many other coatings.

It is correct that it is thin and builds close as to nothing, but at the same time, it does not wear or chip off if not abused stupidly.

Everything has a lifetime, DLC is very long.

Now that is if it is real DLC by Cavidur or some of the other companies that supplies this for the top level racing industry since many years.

Expensive? Yes but probably well worth it. Well, I must be honest, I do not have a quotation for my cams a potentially the rockers too.

Then I guess that the cast cams must be evaluated for compatibility and setting of processing specs with nitriding and here I have a problem. I do not have the material specs on the third and last set of cams. They were not done by me.

DLC will be applicable and on any cast or billet steel as fas as I have been told.

My first set of cams failed due to lack of good control process in the flame hardening.

Second set were improved SIS 0125 steel that was induction hardened.

It worked well until I ran the car through a winter in Italy and started diluting the oil with a very rich fuel setting in combination with high ring blowby.

If not fixing the problem nor changing oil on frequent basis, it will kill the frictional properties....I asked for it.

Anyway, DLC coating does not "wear off" as many other coatings.

It is correct that it is thin and builds close as to nothing, but at the same time, it does not wear or chip off if not abused stupidly.

Everything has a lifetime, DLC is very long.

Now that is if it is real DLC by Cavidur or some of the other companies that supplies this for the top level racing industry since many years.

Expensive? Yes but probably well worth it. Well, I must be honest, I do not have a quotation for my cams a potentially the rockers too.

Then I guess that the cast cams must be evaluated for compatibility and setting of processing specs with nitriding and here I have a problem. I do not have the material specs on the third and last set of cams. They were not done by me.

DLC will be applicable and on any cast or billet steel as fas as I have been told.

- Piledriver

- Moderator

- Posts: 22760

- Joined: Sat Feb 16, 2002 12:01 am

- Piledriver

- Moderator

- Posts: 22760

- Joined: Sat Feb 16, 2002 12:01 am

Yes, he did, IIRC from several sources with the same ... results.Unkl Ian wrote:Didn't Jake try DLC on lifters and cams ?

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

M-Owen

- Posts: 64

- Joined: Wed Dec 05, 2007 5:23 pm

I have been considering cutting and pinning the cams back together, forgive me if this sounds stupid . When you refer to pinning the cams back together are you drilling and adding a pin thru the center and welding? or are you placing a dowel thru the center and cross pinning? I think I might be overthinking the subject as often I do so I thought I would ask.

- Piledriver

- Moderator

- Posts: 22760

- Joined: Sat Feb 16, 2002 12:01 am

Bobtail posted somewhing awhile back on his setup, been awhile, but I THINK it used a dowel that was pinned in place at both ends, so the head spacing and lobe orientation could be set indepenently.M-Owen wrote:I have been considering cutting and pinning the cams back together, forgive me if this sounds stupid . When you refer to pinning the cams back together are you drilling and adding a pin thru the center and welding? or are you placing a dowel thru the center and cross pinning? I think I might be overthinking the subject as often I do so I thought I would ask.

Also IIRC he had to use the lobes on either end and cut out the middle pair.

He at least used to have a load of pics and info on his website...

I have always wondered if you started the procedure with the steel sandwich plates on the block, could you use the 911 stud pattern, or does it interfere with the through bolt pattern??

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

To be honest, I have no idea how the cut and pin method is done.

Bobtail/Russ Fellows are the guys to ask.

Welding is for sure not involved on a cast cam more than to build up hardwelding or emergency repairs on the lobes prior to re-grinding.

Can not see it being used for rotational strength.

I could see "step cutting" it and then maybe a pin.

Bobtail/Russ Fellows are the guys to ask.

Welding is for sure not involved on a cast cam more than to build up hardwelding or emergency repairs on the lobes prior to re-grinding.

Can not see it being used for rotational strength.

I could see "step cutting" it and then maybe a pin.

- Frallan

- Posts: 667

- Joined: Sun Mar 30, 2003 12:01 am

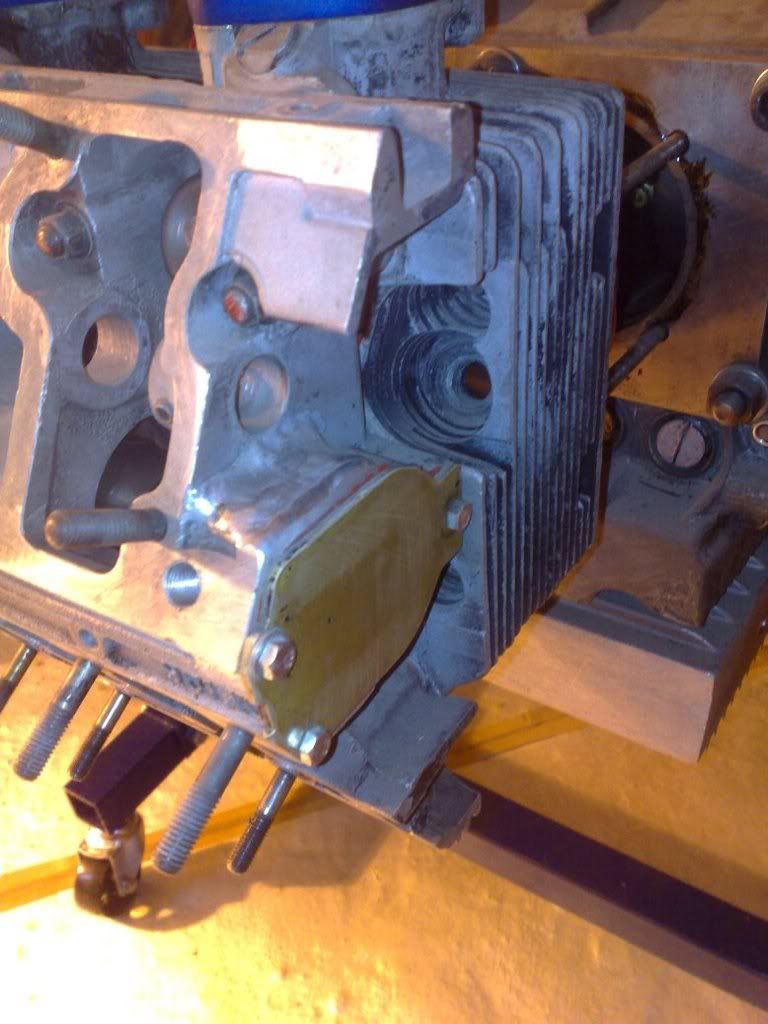

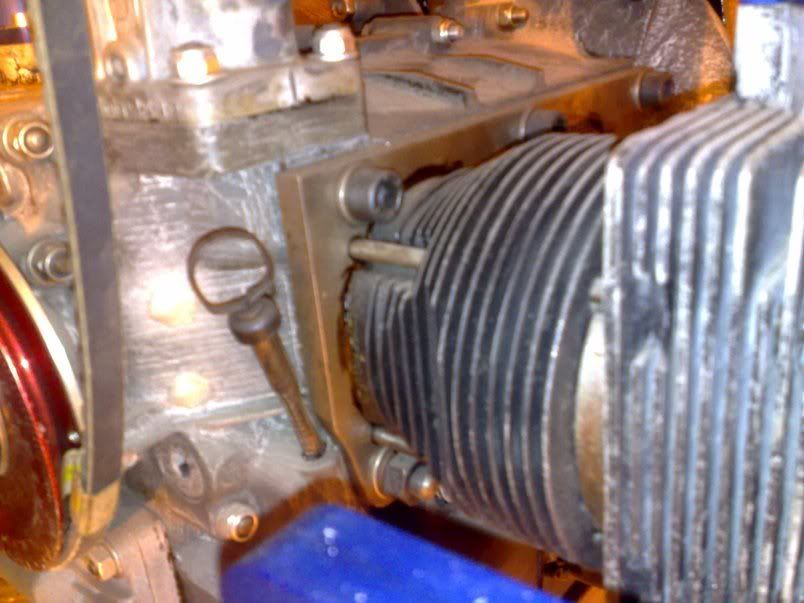

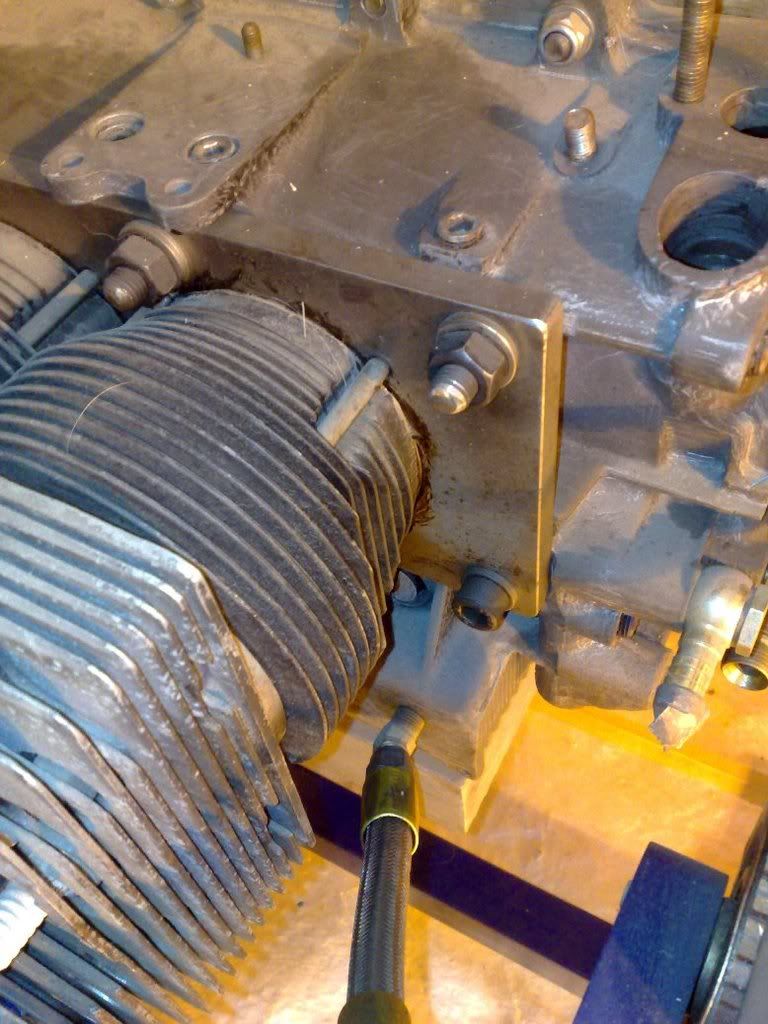

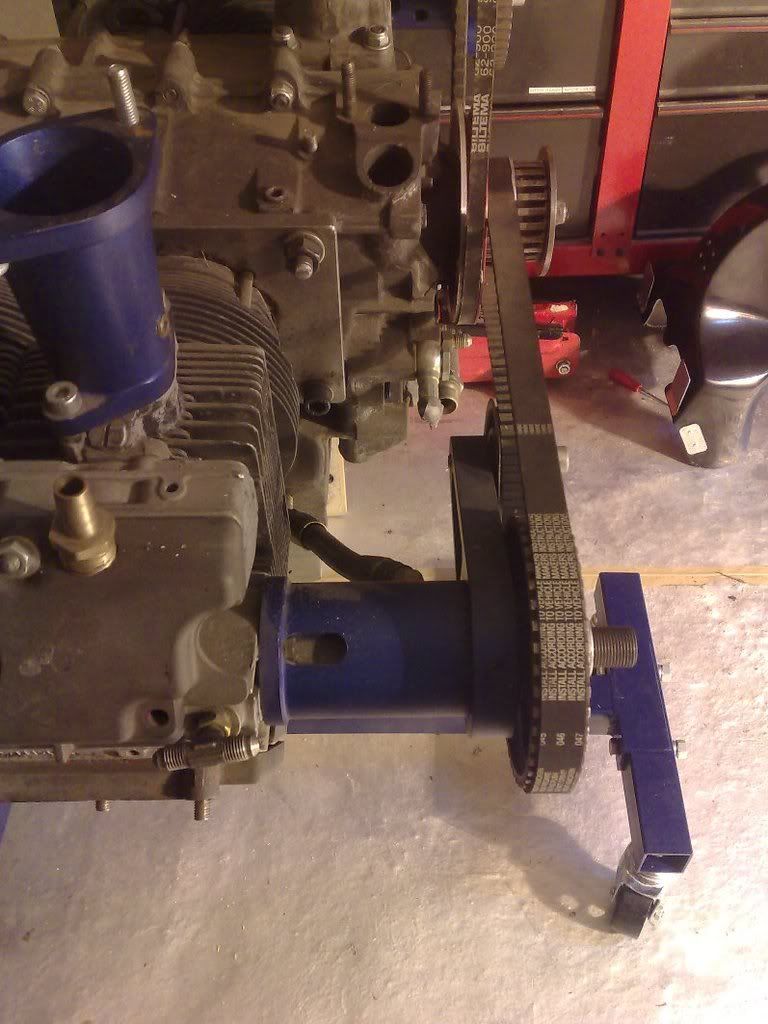

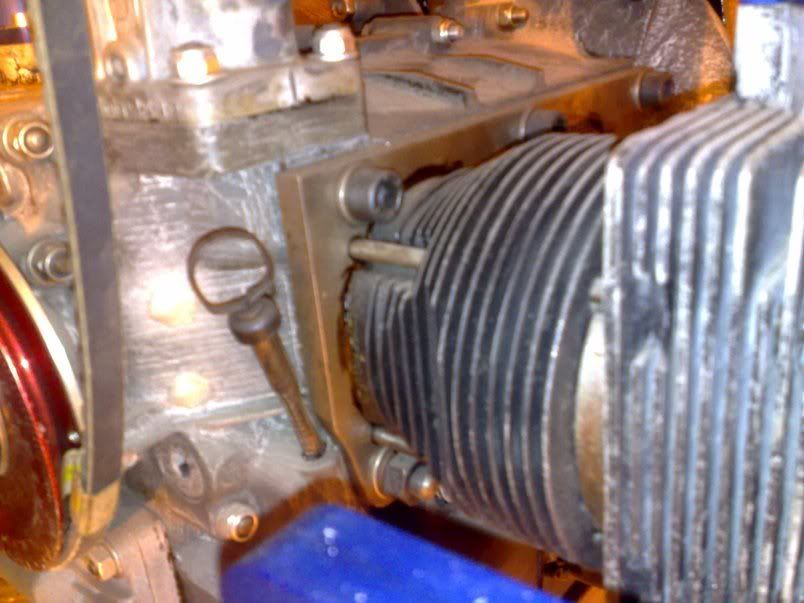

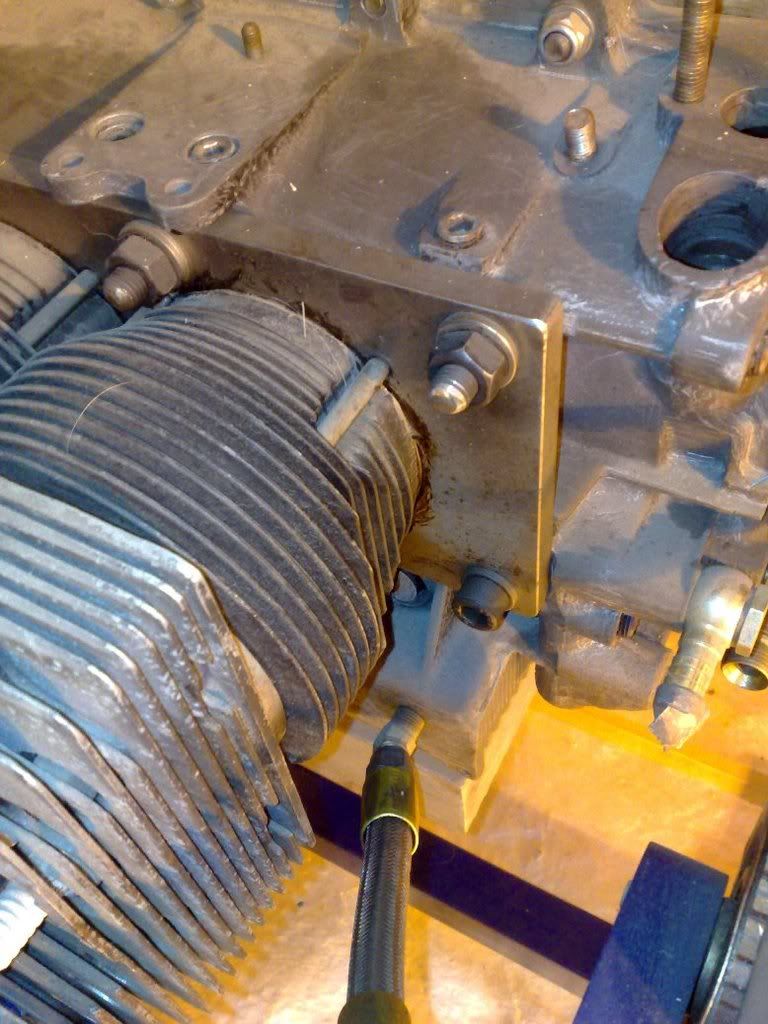

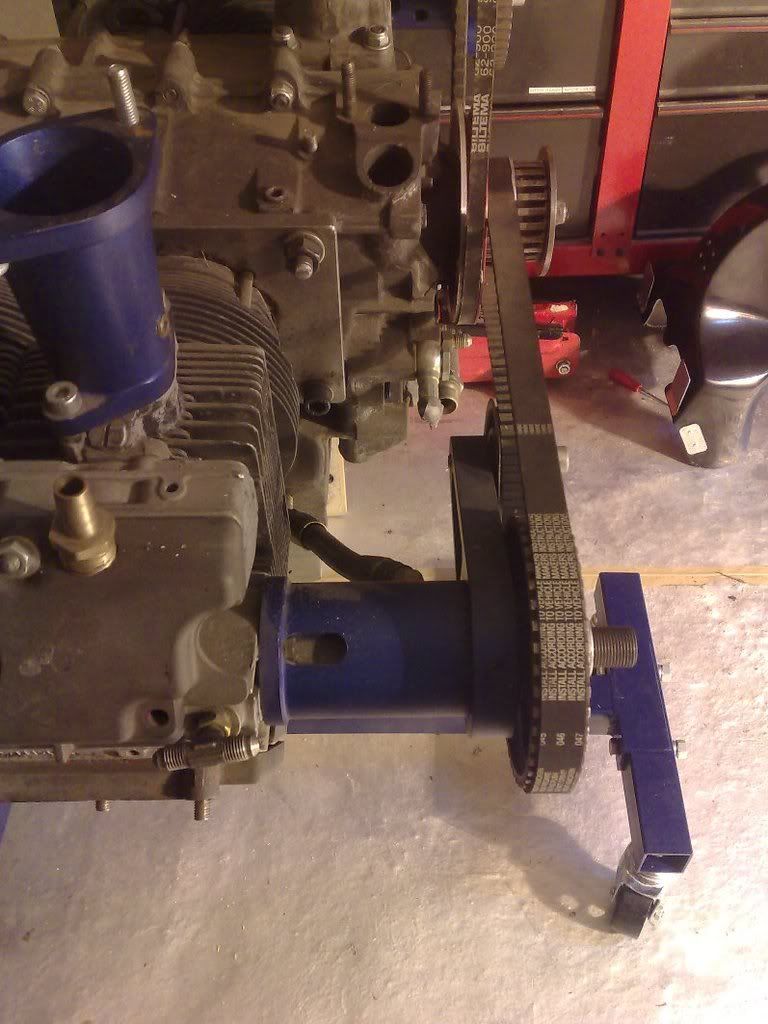

I know these pictures and my old engine is T1 but it is still to demonstrate the 911 conversion and the incredible strength achieved by adding steel plates on an engine block.

The same can be done to TIV, although I do not beleive it is needed for strength but rather if needed to combine with relocating the stud pattern.

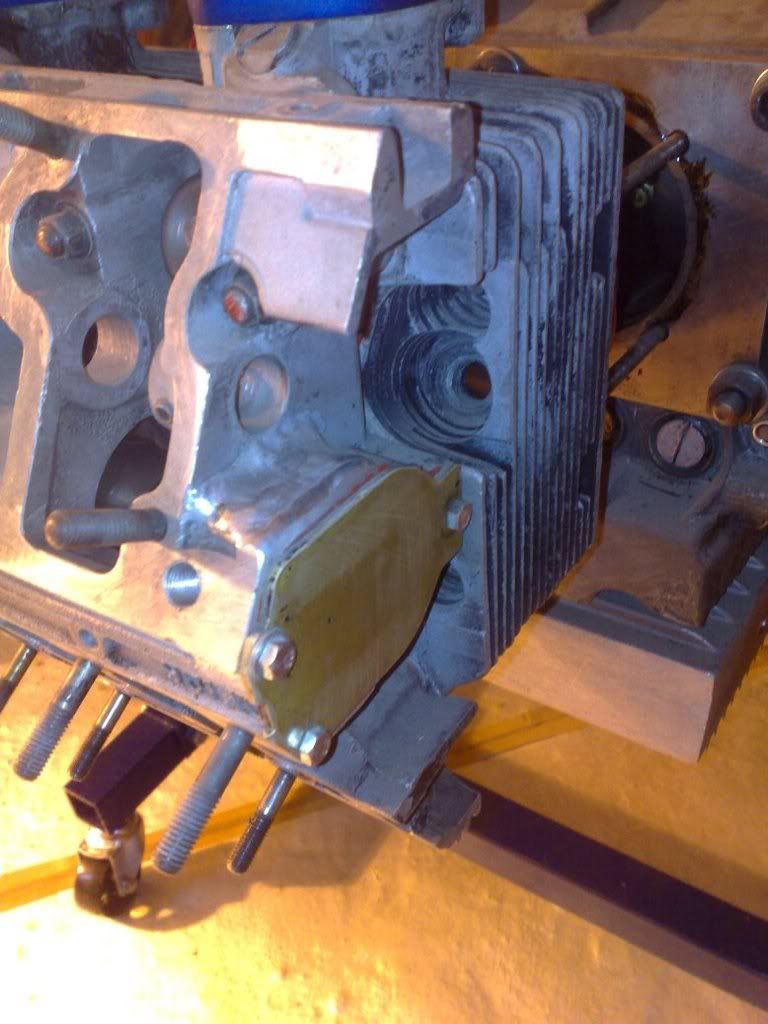

Welded end of camhousing for the cambearing on right hand side. Not needed on left side.

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... wbolts.jpg

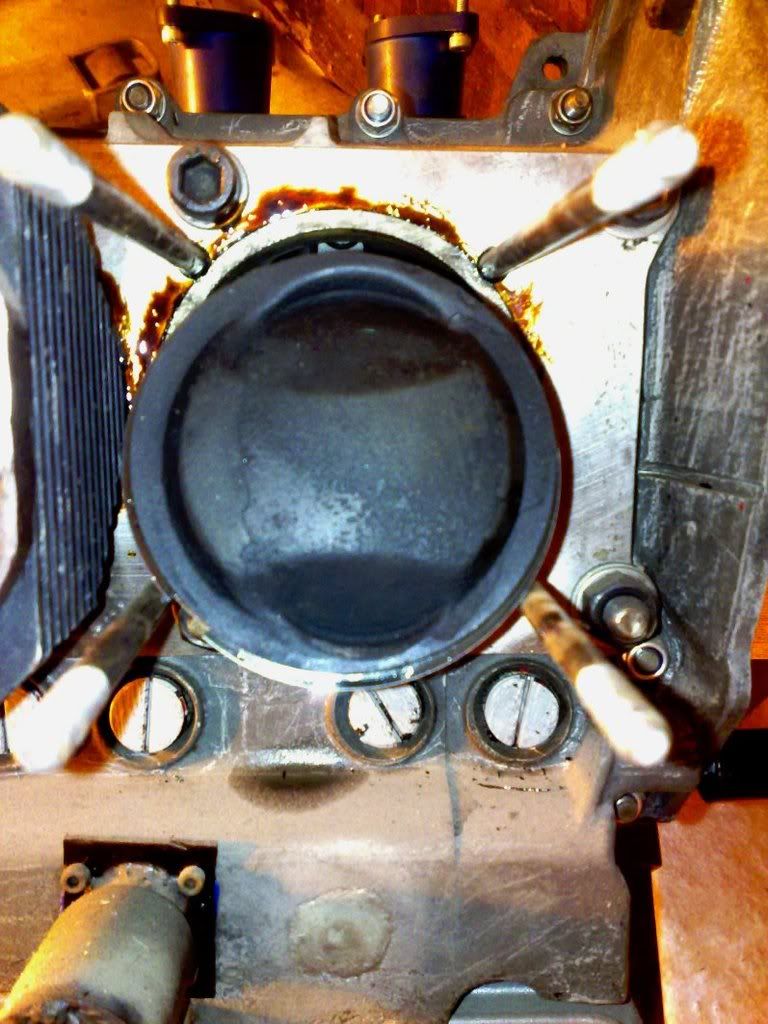

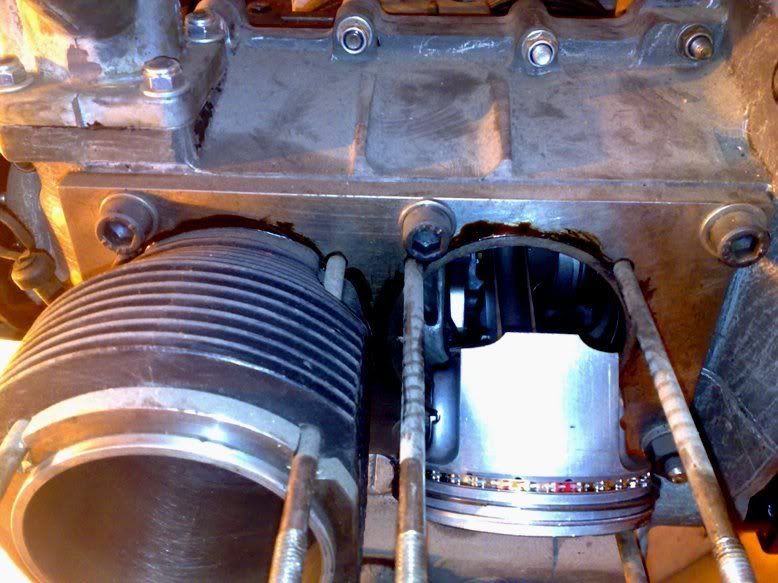

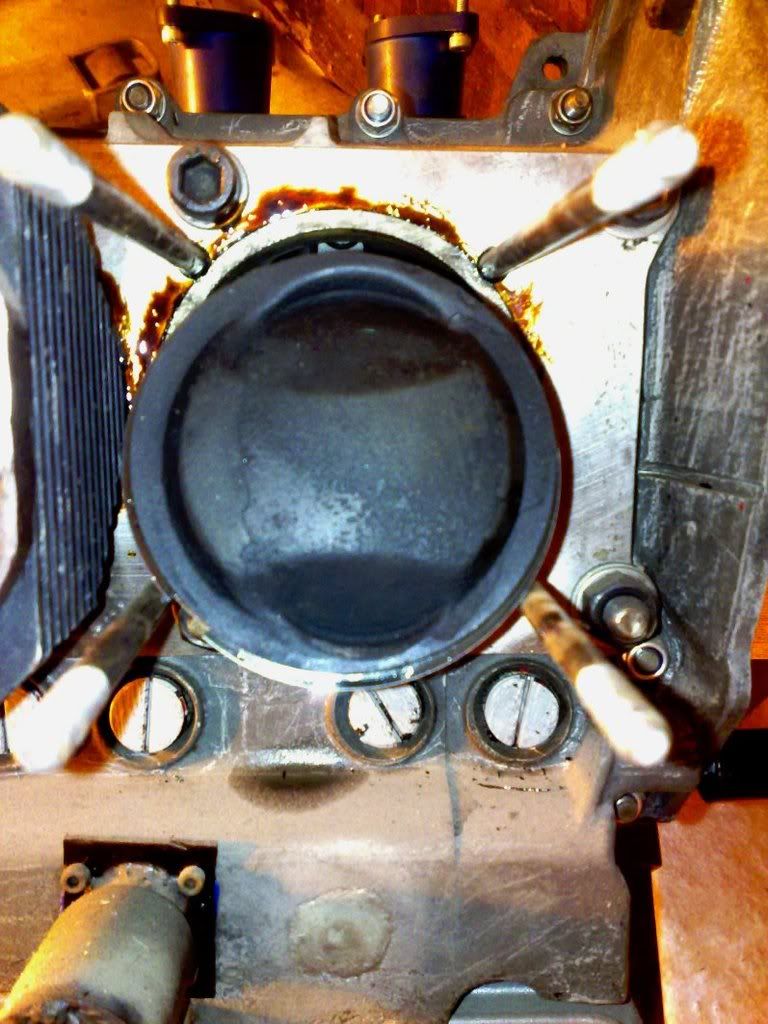

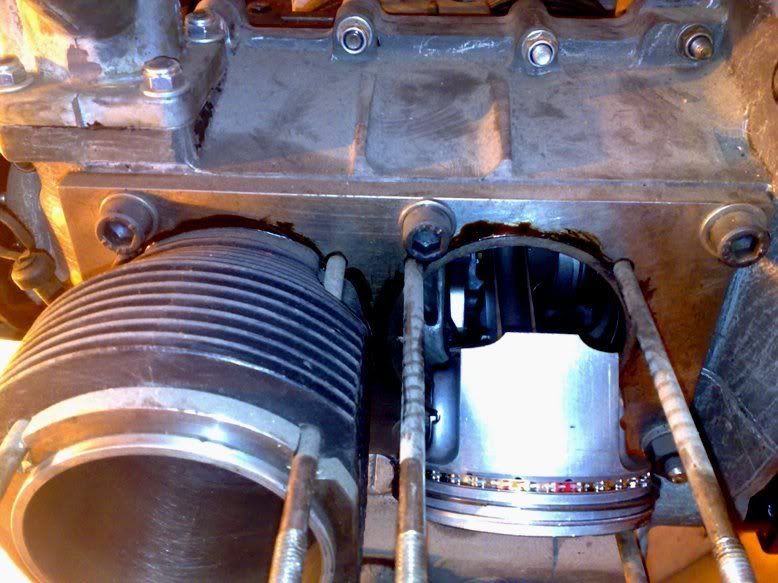

Here is a good view why I would not do this type of offset style. Just imagine how little meat I I have in the right hand side of the intake valve notch and the top ring.

http://i153.photobucket.com/albums/s207 ... piston.jpg

http://i153.photobucket.com/albums/s207 ... deview.jpg

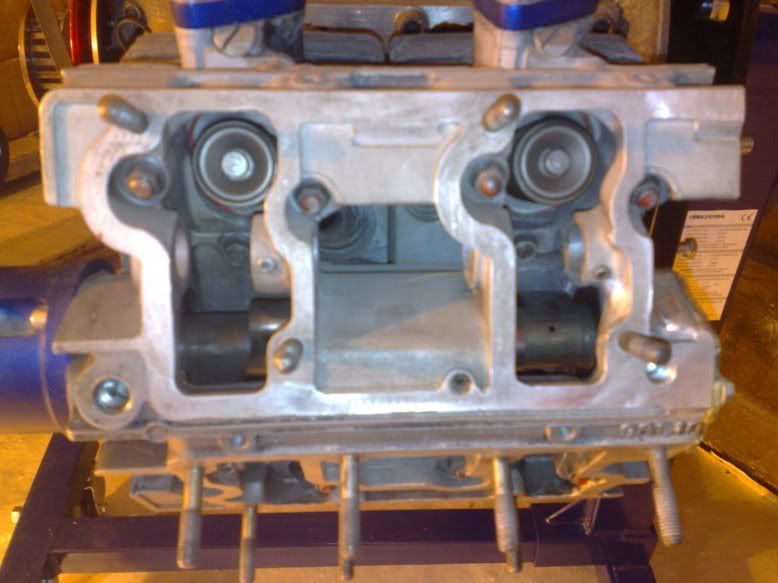

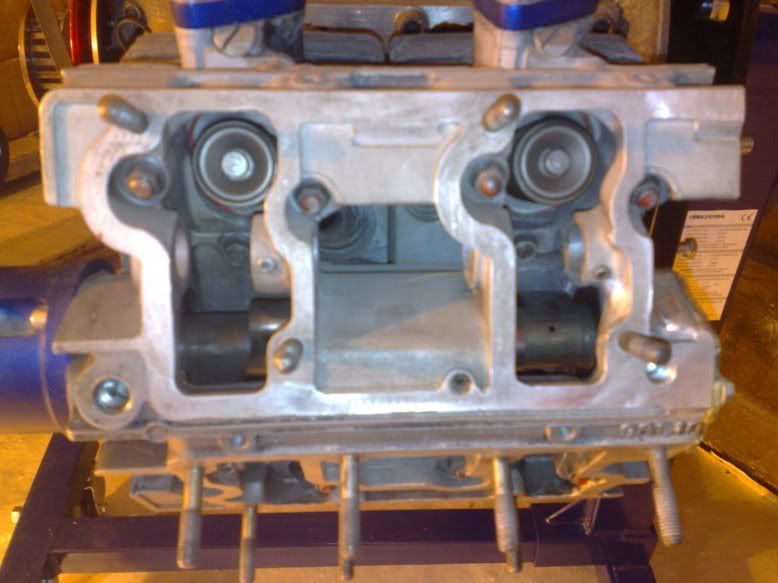

Here is good overview of the camhousing and also the oil hole for the camlobes is visible.

On my previous cams I did not hav ethe hollow cam but rather a spraybar above the cams.

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... wplate.jpg

The same can be done to TIV, although I do not beleive it is needed for strength but rather if needed to combine with relocating the stud pattern.

Welded end of camhousing for the cambearing on right hand side. Not needed on left side.

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... wbolts.jpg

Here is a good view why I would not do this type of offset style. Just imagine how little meat I I have in the right hand side of the intake valve notch and the top ring.

http://i153.photobucket.com/albums/s207 ... piston.jpg

http://i153.photobucket.com/albums/s207 ... deview.jpg

Here is good overview of the camhousing and also the oil hole for the camlobes is visible.

On my previous cams I did not hav ethe hollow cam but rather a spraybar above the cams.

http://i153.photobucket.com/albums/s207 ... ousing.jpg

http://i153.photobucket.com/albums/s207 ... wplate.jpg

- Wally

- Posts: 4564

- Joined: Mon Oct 28, 2002 12:01 am

You relocated the cylinders in the head spigot

That is an interesting way to overcome the difference in cylinder spacing I must say! No extra welding inside the 911 head done to be able to 'seat' the top of the cylinder on the side that moves inward to the head combustion chamber?

I also like the ring around the 'neck' of the Oettinger 90mm alu cylinder: for extra strength due to turbo use I suppose huh? Is it steel or alu? Looks like alu.

Very cool Frallan!

Tnx,

Walter

That is an interesting way to overcome the difference in cylinder spacing I must say! No extra welding inside the 911 head done to be able to 'seat' the top of the cylinder on the side that moves inward to the head combustion chamber?

I also like the ring around the 'neck' of the Oettinger 90mm alu cylinder: for extra strength due to turbo use I suppose huh? Is it steel or alu? Looks like alu.

Very cool Frallan!

Tnx,

Walter

T4T: 2,4ltr Type 4 Turbo engine, 10.58 1/4 mi in a streetlegal 1303

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

"Mine isn't turbo'd to make a slow engine fast, but to make a fast engine insane" - Chip Birks

- Piledriver

- Moderator

- Posts: 22760

- Joined: Sat Feb 16, 2002 12:01 am