Hard Line For Inside Tunnel

- Clatter

- Posts: 2046

- Joined: Sun Apr 28, 2002 1:01 am

Hard Line For Inside Tunnel

Here I have the tunnel completely open on my Type 3 build...

I can do any kind of fuel lines i want.

The plan is to run hard lines, and luckily, with the type 3, use bulkhead fittings at each end of the tunnel.

Ideally, This would be forever, and big enough for any FI system in the future.

And, more importantly, it will be sealed up, entombed forever within the tunnel, never to be retrieved.

Some of the hard lines/tube adaptors i see have a max PSI rating of 50PSI.

Would this be likely to ever be exceeded?

Stock FI can be at 45PSI, so this seems dangerously close?

Aluminum?

Stainless?

JIC?

Brand?

If you had your druthers,

What would you use to plumb your car for your dream FI system?

Got a link to a speific product?

Please and Thanks

I can do any kind of fuel lines i want.

The plan is to run hard lines, and luckily, with the type 3, use bulkhead fittings at each end of the tunnel.

Ideally, This would be forever, and big enough for any FI system in the future.

And, more importantly, it will be sealed up, entombed forever within the tunnel, never to be retrieved.

Some of the hard lines/tube adaptors i see have a max PSI rating of 50PSI.

Would this be likely to ever be exceeded?

Stock FI can be at 45PSI, so this seems dangerously close?

Aluminum?

Stainless?

JIC?

Brand?

If you had your druthers,

What would you use to plumb your car for your dream FI system?

Got a link to a speific product?

Please and Thanks

Speedier than a Fasting Bullet!

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

-

jhoefer

- Posts: 195

- Joined: Wed Oct 05, 2011 2:30 pm

Re: Hard Line For Inside Tunnel

Those tube adapter fittings you mention are just a compression fitting (compression olive slides over tube, then clamped between the two halves of the fitting) hence the low pressure rating. If you want to do AN fittings, get a flaring tool to flare the tubing and then you use "tube sleeves" + "tube nuts" for the AN hardline female side, and a standard AN male fitting for the other side. Hose fittings are female, so you need a male-male union between the hard line and the hose fitting, but bulkhead fittings are male-male, so in your case, you'd just use those.

Can't really say how it "should be" done, as there's a lot of personal considerations to that.

Can't really say how it "should be" done, as there's a lot of personal considerations to that.

-

Clonebug

- Posts: 4745

- Joined: Thu Feb 15, 2007 9:28 pm

Re: Hard Line For Inside Tunnel

You can just slide a FI hose on the tubing and use a FI clamp.

It will save you about $100.00 in fittings and headaches.

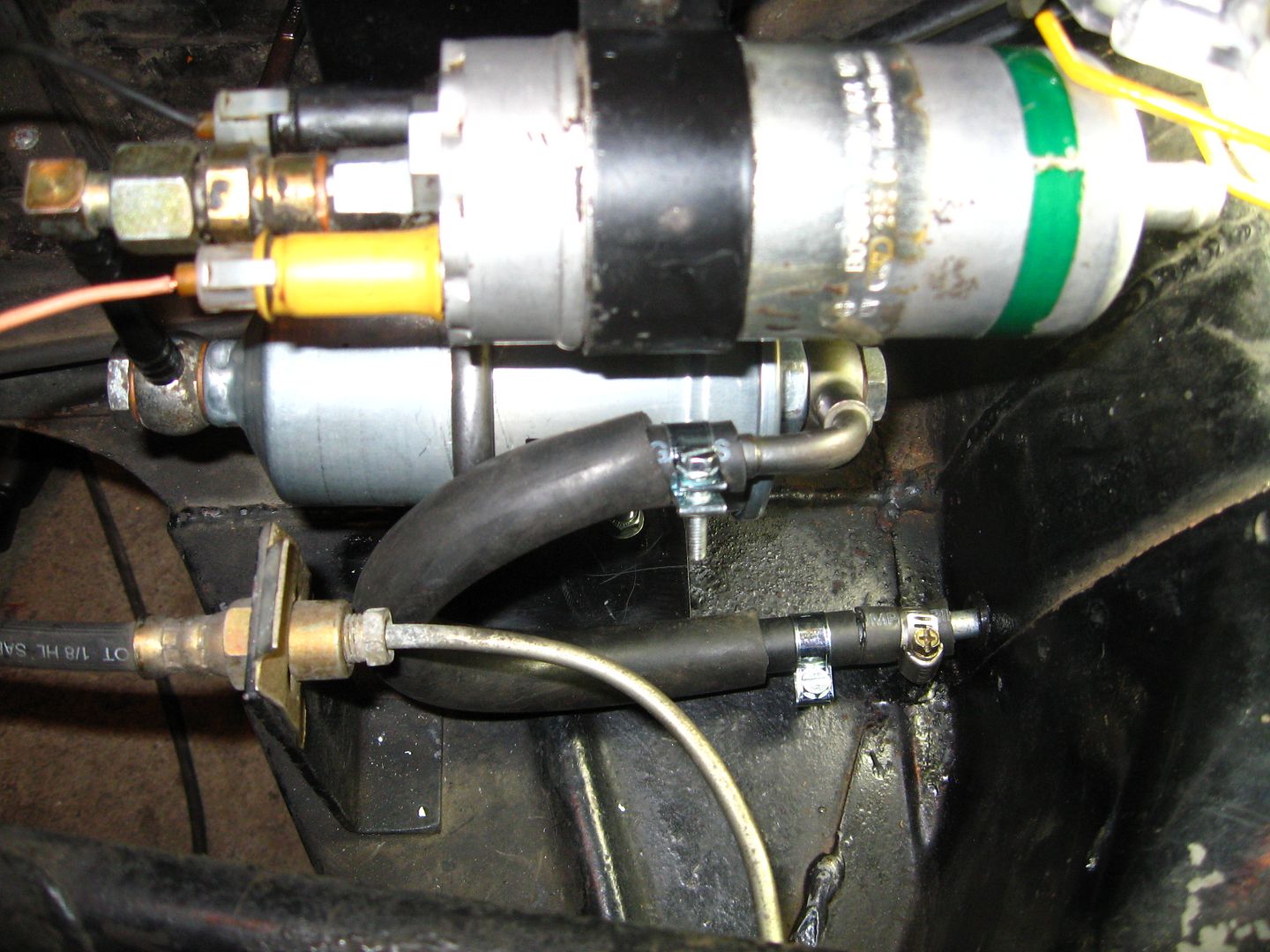

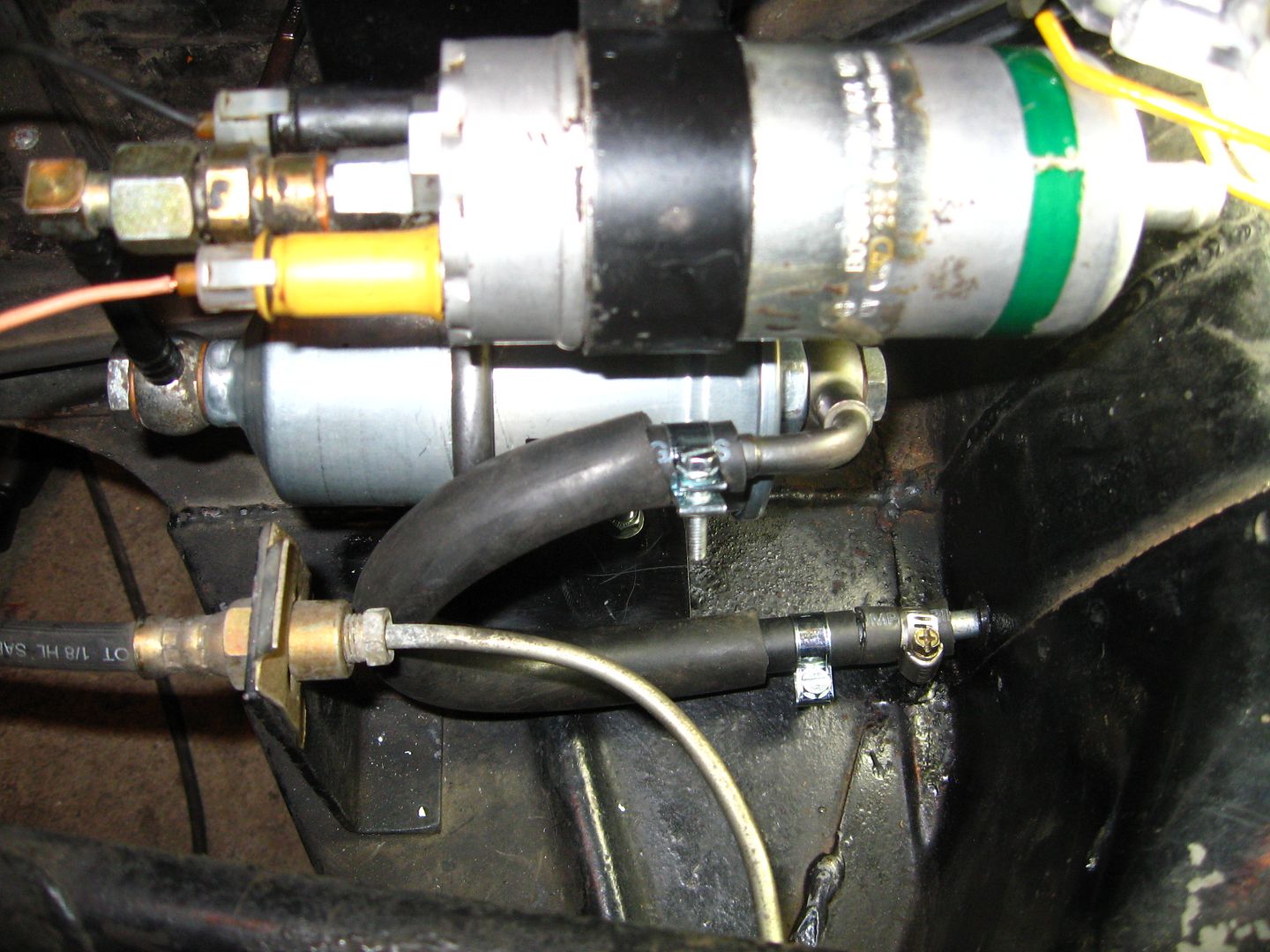

I used hose on the lines in and out of the tunnel and then built hard lines to the FI rails.

Not a drip or any issue in the 7000 plus miles I've put on it so far.

Make sure you use FI rated hose and clamps.

It will save you about $100.00 in fittings and headaches.

I used hose on the lines in and out of the tunnel and then built hard lines to the FI rails.

Not a drip or any issue in the 7000 plus miles I've put on it so far.

Make sure you use FI rated hose and clamps.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.

- risk

- Posts: 335

- Joined: Mon Nov 19, 2007 2:43 pm

Re: Hard Line For Inside Tunnel

I used stainless 3/8" tubing and flared the ends 37 degrees. The nuts and sleeves are pretty cheap.. the flaring tool, however, will set you back some. But you will be able to flare hard lines on just about anything using the 37 degree AN style fittings.

Tube nuts purchased from discount hydraulic hose.com

http://www.discounthydraulichose.com/product_p/318.htm

And the sleeves

http://www.discounthydraulichose.com/product_p/319.htm

I used rubber grommets where they went throught the tunnel, and made some brackets to secure the tubing.

Tube nuts purchased from discount hydraulic hose.com

http://www.discounthydraulichose.com/product_p/318.htm

And the sleeves

http://www.discounthydraulichose.com/product_p/319.htm

I used rubber grommets where they went throught the tunnel, and made some brackets to secure the tubing.

- Piledriver

- Moderator

- Posts: 22764

- Joined: Sat Feb 16, 2002 12:01 am

Re: Hard Line For Inside Tunnel

If you have an industrial fitting supply in your area, there are "compression" fittings that exist that are good to >3000 PSI, and are very reasonably priced, esp compared to AN fittings... Commonly used in industry.

Swagelok and Parker make very similar (and largely compatible) fittings.

https://www.swagelok.com/products/fittings.aspx

Available in brass, SS, mild steel, Teflon and probably wild alloys if needed.

Just throwing out an alternative somewhere in between rubber hose and AN fittings.

I use them all the time at work, hard to screw up and very reliable.

Swagelok and Parker make very similar (and largely compatible) fittings.

https://www.swagelok.com/products/fittings.aspx

Available in brass, SS, mild steel, Teflon and probably wild alloys if needed.

Just throwing out an alternative somewhere in between rubber hose and AN fittings.

I use them all the time at work, hard to screw up and very reliable.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Clatter

- Posts: 2046

- Joined: Sun Apr 28, 2002 1:01 am

Re: Hard Line For Inside Tunnel

Thanks for the suggestions guys.

Hard to know which way to go...

Think aluminum tubing is OK?

3/8" a good diameter?

Hard to know which way to go...

Think aluminum tubing is OK?

3/8" a good diameter?

Speedier than a Fasting Bullet!

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

- Piledriver

- Moderator

- Posts: 22764

- Joined: Sat Feb 16, 2002 12:01 am

Re: Hard Line For Inside Tunnel

Brake line (copper/nickel corrosion resistant alloy or galvanized) or SS.

Aluminum has ~same cracking issue over time as copper tubing, and is very easy to damage.

...Unless you are trying to shave a few ounces on a race car.

Aluminum has ~same cracking issue over time as copper tubing, and is very easy to damage.

...Unless you are trying to shave a few ounces on a race car.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- jzsquared

- Posts: 17

- Joined: Sat Dec 20, 2014 4:36 pm

Re: Hard Line For Inside Tunnel

The compression fitting work fine from Earls as I ran here. I purchased a 25' role of stainless 5/16 line and had so much I ran new to and from lines.

I also didn't care for the return/feed line on a tee so I welded a AN6 bung to tank for return. Honestly when I do my next car I will just use the stock line for return and weld a AN4 bung to tank for the smaller line. Be careful what fuel line you run if there is ethanol in the fuel it will eat away standard rubber line. Jeg's sells ethanol proof stuff it's a little more expensive but worth it to me

- jzsquared

- Posts: 17

- Joined: Sat Dec 20, 2014 4:36 pm

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Hard Line For Inside Tunnel

Since you have the tunnel opened up prudent advice would be "shoot for the moon" now and add all lines that you might need for FI. In a Hot VW issue a few years back did a pan for show; they replaced the lines running through the tunnel front to rear. I think it can be searched or, if you want and are not in a big hurry, I might be able to find the issue number for you.

Piledriver gave you some great information on what to use and not to use hard line wise and, if it were me, I would stick with it. If you are going to use caustic fuels and can deal with the SS/CRES (forming/flaring/welding) I would sure look into that direction.

As advice: I would not use braided line SS or braided rubber; e.g., soft lines of any kind nor use any connectors inside of the tunnel mil-spec or not! If something goes wrong; like the lines plug (like they can do after so long with caustic liquids running through them [I consider fuel, brake fluid, etc. as caustic) or the fittings loosen up, which they could possibly do, then you would be in deep doo-doo and have to "lift the lid" on the tunnel again.

Also remember that fittings are heavy and can cause the lines to flex which could mean that if they were in the tunnel you could get some banging going on plus the soft lines could fail earlier than normal.

For what it is worth and remember: my advice is worth a bit less than you paid for it.

Lee

Edit: I forgot to mention that there are minimum bend radiuses for braided line with SS being a bigger radius than rubber line would be. Remember that the material on the inside of a bend has to compact and the material on the outside of a bend has to stretch so any braiding, especially the SS braiding is going to limit how tight of a bend you can make.

L

Piledriver gave you some great information on what to use and not to use hard line wise and, if it were me, I would stick with it. If you are going to use caustic fuels and can deal with the SS/CRES (forming/flaring/welding) I would sure look into that direction.

As advice: I would not use braided line SS or braided rubber; e.g., soft lines of any kind nor use any connectors inside of the tunnel mil-spec or not! If something goes wrong; like the lines plug (like they can do after so long with caustic liquids running through them [I consider fuel, brake fluid, etc. as caustic) or the fittings loosen up, which they could possibly do, then you would be in deep doo-doo and have to "lift the lid" on the tunnel again.

Also remember that fittings are heavy and can cause the lines to flex which could mean that if they were in the tunnel you could get some banging going on plus the soft lines could fail earlier than normal.

For what it is worth and remember: my advice is worth a bit less than you paid for it.

Lee

Edit: I forgot to mention that there are minimum bend radiuses for braided line with SS being a bigger radius than rubber line would be. Remember that the material on the inside of a bend has to compact and the material on the outside of a bend has to stretch so any braiding, especially the SS braiding is going to limit how tight of a bend you can make.

L

-

Bad Bob

- Posts: 112

- Joined: Wed Nov 12, 2014 10:47 pm

Re: Hard Line For Inside Tunnel

Whatever you end up using, make sure you clamp the lines about every 2 feet to the side or the bottom of the tunnel. Even SS lines will crack if you let them vibrate. These clamps are around 40 cents ea. When your'e done admiring your sexy fuel line install, slide the shift rod into position and make sure everything will clear.

You do not have the required permissions to view the files attached to this post.

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Hard Line For Inside Tunnel

Good advice Bob, soft lines should be clamped closer together to stop sag and allow places for air/air bubbles to collect.