Lowering For Handling

- Jadewombat

- Posts: 1447

- Joined: Sat Jun 22, 2002 12:01 am

Re: Lowering For Handling

Don't go too low, you may run into issues like this (about midway down the page):

http://germanlook.net/forums/showthread ... 53&page=67

http://germanlook.net/forums/showthread ... 53&page=67

-

Ol'fogasaurus

- Posts: 17760

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Lowering For Handling

If you are interested in prepping th CV joints, most of the CV prep on the web is for 930s but it has to be close enough that you can get the idea of what to do from them.

http://www.youtube.com/watch?v=PZOCjwSXgkQ

Here is some more information:

http://www.dune-buggy.com/techtips/cv_j ... ishing.htm

http://www.outfrontmotorsports.com/cv_assembly.htm

Tools for polishing the (930) CVs:

http://www.racereadyproducts.com/race-p ... hing-bits/

“Fine tuning the CV joints.

For off-road use, it’s better if the whole joint is kept just a little loose. There may be a slight increase in noise, but it shouldn’t bother you during racing. The benefits are that the joints will survive heavy knocks, and they’ll also handle the large, rapid changes in direction, as the suspension cycles up and down.

A new CV joint is quite a rigid assembly, making it difficult to rotate the internals by hand. If you did manage to rotate the innards of a new joint to the point where the balls could be pulled out, you’d have a hell of a job reassembling it all.

Race CVs are fine tuned by lightening the exterior of the housing, and polishing and relieving the internals. The housing is made from alloy steel, but only the inner tracks are induction heat-treated. This means narrow grooves can quite easily be machined away to reduce the rotating mass and unsprung weight. Do not buy regular lightened "race" CVs, as they have a wide area of material machined off the outsides of the housings, and can’t be fitted inside the R6’s bearings.

The depth of the case hardening of the tracks is in the vicinity of 1.2mm to 2.5mm, so some grinding to a depth of 0.25mm by specialist CV reconditioners (to accept 0.50mm oversize balls) is possible, and light honing by racers is perfectly acceptable.

Highly accurate machines using CBN coated grinding “stones” are used in the regrinding process, and should not be attempted with a hand held die-grinder in the home workshop.

Don’t use any pitted or scored parts, as they will promote rapid wear and consequently, the whole CV joint could fail. If you find any pitting in the cross grooves of a star or housing, just use one of your spare CVs, but don’t throw out any damaged stars yet!

Part of the housing and star manufacturing process involves broaching the cross grooves. The drag marks on the surface of the grooves are usually clearly visible. All the bearing surfaces need to be polished with aluminum oxide abrasives.

Pick a sound, clean star and clamp it in the vice so about half of it is above the vice jaws. Mount an expanding arbor in the die-grinder, and push a 80 grit sanding sleeve onto it. Holding the die grinder with both hands, lightly polish the entire surface of each cross groove. Don’t apply too much pressure, and keep the axis of the arbor aligned with the axis of the groove at all times. The object is to achieve a uniform light grey finish with no shiny spots.

Clamp the CV housings in the vice, and give their cross grooves a light polish too.

The cages require a lot of fettling, but being a difficult, frail item, are easier done while being held in the hand. Put on the gloves, and holding a cage in one hand, give the windows a very light “lick” with the drum sander. Make sure the drum’s axis remains at 90 degrees to the cage’s axis, and keep the sander moving in a controlled circular motion around the inside of the windows. Don’t let it dwell on any one spot, or you will create notches, which the ball could get hung up in. The object of this process is to slightly relieve the windows, while at the same time, softening the edges of the openings to prevent stress risers and subsequent cracks from forming.

Stop frequently, and try a ball in the window. It shouldn’t bind anywhere in the window, and should just be able to drop through without having to be forced.

Finally, very lightly, sand both the inner and outer sharp edges of the windows. Remove the absolute minimum amount of material. Test with a finger, and if it feels sharp, give it another light lick.”

(source: http://www.rorty-design.com/content/CV_joints.htm)

Lee

http://www.youtube.com/watch?v=PZOCjwSXgkQ

Here is some more information:

http://www.dune-buggy.com/techtips/cv_j ... ishing.htm

http://www.outfrontmotorsports.com/cv_assembly.htm

Tools for polishing the (930) CVs:

http://www.racereadyproducts.com/race-p ... hing-bits/

“Fine tuning the CV joints.

For off-road use, it’s better if the whole joint is kept just a little loose. There may be a slight increase in noise, but it shouldn’t bother you during racing. The benefits are that the joints will survive heavy knocks, and they’ll also handle the large, rapid changes in direction, as the suspension cycles up and down.

A new CV joint is quite a rigid assembly, making it difficult to rotate the internals by hand. If you did manage to rotate the innards of a new joint to the point where the balls could be pulled out, you’d have a hell of a job reassembling it all.

Race CVs are fine tuned by lightening the exterior of the housing, and polishing and relieving the internals. The housing is made from alloy steel, but only the inner tracks are induction heat-treated. This means narrow grooves can quite easily be machined away to reduce the rotating mass and unsprung weight. Do not buy regular lightened "race" CVs, as they have a wide area of material machined off the outsides of the housings, and can’t be fitted inside the R6’s bearings.

The depth of the case hardening of the tracks is in the vicinity of 1.2mm to 2.5mm, so some grinding to a depth of 0.25mm by specialist CV reconditioners (to accept 0.50mm oversize balls) is possible, and light honing by racers is perfectly acceptable.

Highly accurate machines using CBN coated grinding “stones” are used in the regrinding process, and should not be attempted with a hand held die-grinder in the home workshop.

Don’t use any pitted or scored parts, as they will promote rapid wear and consequently, the whole CV joint could fail. If you find any pitting in the cross grooves of a star or housing, just use one of your spare CVs, but don’t throw out any damaged stars yet!

Part of the housing and star manufacturing process involves broaching the cross grooves. The drag marks on the surface of the grooves are usually clearly visible. All the bearing surfaces need to be polished with aluminum oxide abrasives.

Pick a sound, clean star and clamp it in the vice so about half of it is above the vice jaws. Mount an expanding arbor in the die-grinder, and push a 80 grit sanding sleeve onto it. Holding the die grinder with both hands, lightly polish the entire surface of each cross groove. Don’t apply too much pressure, and keep the axis of the arbor aligned with the axis of the groove at all times. The object is to achieve a uniform light grey finish with no shiny spots.

Clamp the CV housings in the vice, and give their cross grooves a light polish too.

The cages require a lot of fettling, but being a difficult, frail item, are easier done while being held in the hand. Put on the gloves, and holding a cage in one hand, give the windows a very light “lick” with the drum sander. Make sure the drum’s axis remains at 90 degrees to the cage’s axis, and keep the sander moving in a controlled circular motion around the inside of the windows. Don’t let it dwell on any one spot, or you will create notches, which the ball could get hung up in. The object of this process is to slightly relieve the windows, while at the same time, softening the edges of the openings to prevent stress risers and subsequent cracks from forming.

Stop frequently, and try a ball in the window. It shouldn’t bind anywhere in the window, and should just be able to drop through without having to be forced.

Finally, very lightly, sand both the inner and outer sharp edges of the windows. Remove the absolute minimum amount of material. Test with a finger, and if it feels sharp, give it another light lick.”

(source: http://www.rorty-design.com/content/CV_joints.htm)

Lee

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Lowering For Handling

Hi AX,

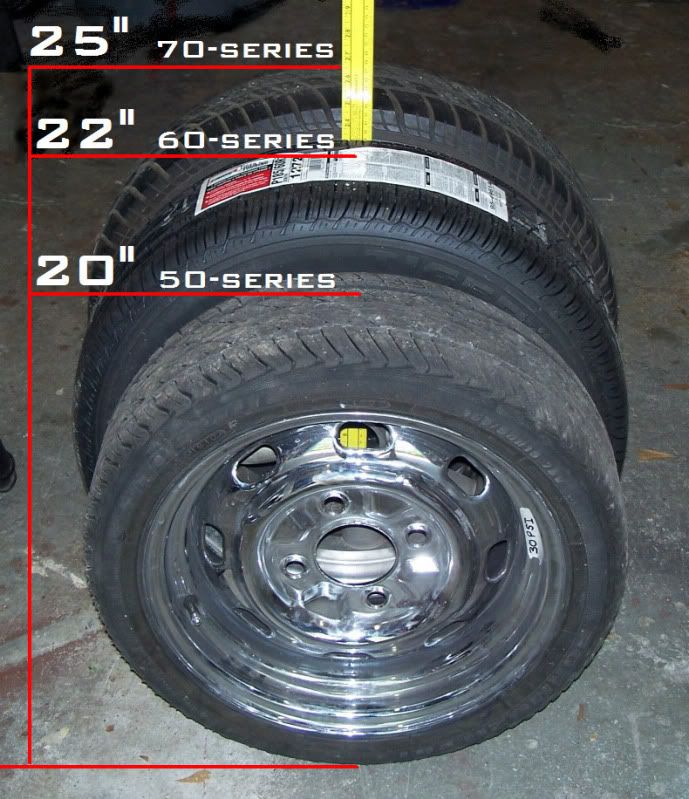

The least complicated way to lower is with low profile tires. Note all of the above on 15" wheels.

Drop spindles, like Marc describes, are next, but need a reindexing of the rear torsion bars -- unless you go to adjustable rear spring plates.

The spring plates are a job to install, but once on, make life so much easier.

FJC

-

Project AX

- Posts: 4

- Joined: Wed Mar 28, 2012 12:05 pm

Re: Lowering For Handling

I looked on that page and i believe your talking about "scrub radius"? I don't quite get what scrub radius is? Is it about how caster angle effects the wheels???Jadewombat wrote:Don't go too low, you may run into issues like this (about midway down the page):

http://germanlook.net/forums/showthread ... 53&page=67

Yes I know that a lower profile tire is always best. Im just trying to find out how high I need to re-raise my slammed Linkpin front end to have a good starting point to tune.

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Lowering For Handling

Hi Ax,

From the floorpan to the ground you want four inches of clearance.

On a stocker, this is usually about six inches. The two inches of lowering is enough to really help handling, without really hurting suspension geometry.

Here's a good definition of scrub radius:

http://en.wikipedia.org/wiki/Scrub_radius

"The term scrub radius derives from the fact that either in the positive or negative mode, the tire does not turn on its centerline (it scrubs the road in a turn) and due to the increased friction, more effort is needed to turn the wheel"

When we start swapping wheels, lowering suspensions, etc. many inobvious things are changed. This is why I always advise doing the least unless you are either feeling very lucky or really know how to correct for the changes -- if you plan on going fast.

FJC

From the floorpan to the ground you want four inches of clearance.

On a stocker, this is usually about six inches. The two inches of lowering is enough to really help handling, without really hurting suspension geometry.

Here's a good definition of scrub radius:

http://en.wikipedia.org/wiki/Scrub_radius

"The term scrub radius derives from the fact that either in the positive or negative mode, the tire does not turn on its centerline (it scrubs the road in a turn) and due to the increased friction, more effort is needed to turn the wheel"

When we start swapping wheels, lowering suspensions, etc. many inobvious things are changed. This is why I always advise doing the least unless you are either feeling very lucky or really know how to correct for the changes -- if you plan on going fast.

FJC

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Lowering For Handling

Picture an imaginary line running down through the steering axis - on your kingpin car, that's pretty much the centerline of the kingpin - and intersecting the pavement. If that point is exactly at the center of the tire tread, there's zero scrub radius. With zero scrub radius, when you steer the car the tire simply twists about the center of the tread - an ideal situation.Project AX wrote:...I don't quite get what scrub radius is...

If the center of the tread is outboard of the point where the kingpin axis intersects the pavement, you have a positive scrub radius. When the wheel is steered, the tread has to drag ("scrub") around, increasing steering effort. More importantly, with a positive scrub radius each time the tire encounters an obstruction in the road (a tar expansion strip, for example) there's a tendency for that tire to want to steer outward. It's not the same thing as bump steer, but is often confused with it because both can make the car wander when a bump is encountered. Early Super Beetles were cursed with positive scrub radius, a major factor in their propensity to shimmy down the road any time conditions are anything but perfect. The Super front suspension geometry was changed in mid`73 to provide a negative scrub radius (at least with stock width & offset rims) which made a huge improvement.

- GS guy

- Posts: 909

- Joined: Wed Nov 06, 2002 12:01 am

Re: Lowering For Handling

I've read that too little or 0 scrub radius gives too little feedback at the steering wheel when cornering at the limit. Not having driven at the limit (at least not in the dry) I don't know what this "feels" like driving. Maybe fjcamper can comment?

I also read somewhere (IIRC) maximum scrub should be no more than ~1/4 of the tire width? - but that you do want a little scrub for steering feedback - just no too much.

I also read somewhere (IIRC) maximum scrub should be no more than ~1/4 of the tire width? - but that you do want a little scrub for steering feedback - just no too much.

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Lowering For Handling

Hi GS Guy,

When you get down to tuning scrub radius, you are in the advanced class.

On well-prepped full-race McPherson strut cars, the top of the strut is adjustable fore and aft and side to side. Adjusting forwards or backwards changes caster. Adjusting side to side changes camber, and you guessed it -- scrub radius.

Zero scrub, while technically perfect, gives the driver less feedback feel as tire adhesion lessens, but by virtue of lessened friction, is the fastest setup. We get into esoterics here. Drivers "place" the car in turns, and as suspension science has improved, placing has come to mean pick a line and do not deviate from it, as if on rails. By comparison, Racing Type 1 front suspensions tend to make placement a moving target, and require more steering inputs to get through a corner.

"Positive" scrub provides good driver feel but as Marc mentioned, tended to make the "Super Beetle Shimmy" famous. VW went to negative scrub not just to counter-act the magnification of vibration in the struts, but negative scub had another miraculous effect -- if a tire went flat, the car did not pull to the side of the flat so badly.

Negative scrub was Novacaine for suspension feedback. A spec-check will show you many auto makers went to negative scrub.

Turns out what we thought was nature, meaning the pull of the steering toward the bad tire, was just geometry all along. And front wheel drive had a lot to do with manufactuers choices in scrub radius. A powered front ends really changes how steering feels.

The bottom line is, unless you have a McPherson strut front suspension, and a fully adjustable upper suspension mounting plate, you have to learn to live with what you have. That means a change in wheel offsets might ot might not feel good to you, depending on your preferences. But you can personally adjust cheaper than changing the car.

FJC

When you get down to tuning scrub radius, you are in the advanced class.

On well-prepped full-race McPherson strut cars, the top of the strut is adjustable fore and aft and side to side. Adjusting forwards or backwards changes caster. Adjusting side to side changes camber, and you guessed it -- scrub radius.

Zero scrub, while technically perfect, gives the driver less feedback feel as tire adhesion lessens, but by virtue of lessened friction, is the fastest setup. We get into esoterics here. Drivers "place" the car in turns, and as suspension science has improved, placing has come to mean pick a line and do not deviate from it, as if on rails. By comparison, Racing Type 1 front suspensions tend to make placement a moving target, and require more steering inputs to get through a corner.

"Positive" scrub provides good driver feel but as Marc mentioned, tended to make the "Super Beetle Shimmy" famous. VW went to negative scrub not just to counter-act the magnification of vibration in the struts, but negative scub had another miraculous effect -- if a tire went flat, the car did not pull to the side of the flat so badly.

Negative scrub was Novacaine for suspension feedback. A spec-check will show you many auto makers went to negative scrub.

Turns out what we thought was nature, meaning the pull of the steering toward the bad tire, was just geometry all along. And front wheel drive had a lot to do with manufactuers choices in scrub radius. A powered front ends really changes how steering feels.

The bottom line is, unless you have a McPherson strut front suspension, and a fully adjustable upper suspension mounting plate, you have to learn to live with what you have. That means a change in wheel offsets might ot might not feel good to you, depending on your preferences. But you can personally adjust cheaper than changing the car.

FJC

-

Chris V

- Posts: 3391

- Joined: Tue Sep 03, 2002 12:01 am

Re: Lowering For Handling

I've just put 200 miles onto the `69 we've nearly finished...It uses 7" rims up front, ET55, with a CB disc spindle ~7mm and a bolt-on spacer of 25.4mm. Making them something like ET23, and the steering feedback though the stock ~16" steering-wheel is indeed a bit goofy. Dad should be able to deal with it, he has run 10" rims with ~3" backspace on racecars  I haven't yet begun to lean on it, but I've semi-flinged it through a couple intersections to make a traffic-light so far, and it didn't do anything 'surprising'. The lower flange on the framehead measures 4-5/8" from the groun and the center of the rear torsion housing 10-5/8".

I haven't yet begun to lean on it, but I've semi-flinged it through a couple intersections to make a traffic-light so far, and it didn't do anything 'surprising'. The lower flange on the framehead measures 4-5/8" from the groun and the center of the rear torsion housing 10-5/8".

http://en.wikipedia.org/wiki/Kingpin_(automotive_part)

KAI, is a simple idea that needs to be considered even for a small go-kart...it's an important piece of the puzzle.

http://www.diygokarts.com/vb/showthread.php?t=11798

{edited for info}

http://en.wikipedia.org/wiki/Kingpin_(automotive_part)

KAI, is a simple idea that needs to be considered even for a small go-kart...it's an important piece of the puzzle.

http://www.diygokarts.com/vb/showthread.php?t=11798

{edited for info}

Last edited by Chris V on Wed Apr 04, 2012 8:50 pm, edited 1 time in total.

- GS guy

- Posts: 909

- Joined: Wed Nov 06, 2002 12:01 am

Re: Lowering For Handling

The Bug I built many years ago had the typical set-up: '74 IRS/BJ, 3/4" front and rear SAW sway bars, about 1.5" of lowering at the rear and 15x6.5" wheels which had 5" of backspacing (IIRC) - FWD Dodge aluminum wheels. These allowed tucking in the 195mm width tires in nicely under the fenders and gave minimal problems with interference with a little massaging of the rear bump stops and outer beam edges up front.

I though I'd be "smart" and fit an adjustable beam during the restoration, but this was when dropped spindles were gaining popularity so adding them as well seemed like a good idea too! This provided a "very" low front end (too low) as well as increasing the track enough to push the tires sidewalls out just past the fenders. Even with the beam cranked full up, it was still a tad too low, but just finishing up the car I though I could live with it - at least for a while. After getting it running and aligned, I discovered a weird quirk with the handling. Doing "highway" speeds (read: a bit north of 60) on a particular curvy muli-lane highway, I noticed that the steering and car would got from a slight understeer to slight oversteer with small increases (just a few mph) in speed - so you tended to overcorrect when driving and turning the car on a fast sweeper. I could make it do this at will once I discovered how it worked, and it was particularly annoying! Otherwise the car seemed to handle fairly neutral with very slight understeer.

Not sure if this was due to the increased track width/geometry changes from the spindles? Too short a tire (195-50's)? Front just too low (it had extra caster shims)?

I couldn't deal with the ultra low front end (even had to move the "lowered" sway bar to the top of the trailing arms to keep if from hitting all the time) so I bought another set of standard disc spindles and installed them and used the beam adjustments to get the front just slightly lower than the rear. This fixed the too wide track, corrected the ride height and also eliminated the handling "quirk"! No more signs of the quirk - the car maintained the same neutral to slight unsersteer under all driving conditions after that. Never did figure out why it had the driving quirk with the dropped spindles.

In all it's glory (with the dropped spindles):

I though I'd be "smart" and fit an adjustable beam during the restoration, but this was when dropped spindles were gaining popularity so adding them as well seemed like a good idea too! This provided a "very" low front end (too low) as well as increasing the track enough to push the tires sidewalls out just past the fenders. Even with the beam cranked full up, it was still a tad too low, but just finishing up the car I though I could live with it - at least for a while. After getting it running and aligned, I discovered a weird quirk with the handling. Doing "highway" speeds (read: a bit north of 60) on a particular curvy muli-lane highway, I noticed that the steering and car would got from a slight understeer to slight oversteer with small increases (just a few mph) in speed - so you tended to overcorrect when driving and turning the car on a fast sweeper. I could make it do this at will once I discovered how it worked, and it was particularly annoying! Otherwise the car seemed to handle fairly neutral with very slight understeer.

Not sure if this was due to the increased track width/geometry changes from the spindles? Too short a tire (195-50's)? Front just too low (it had extra caster shims)?

I couldn't deal with the ultra low front end (even had to move the "lowered" sway bar to the top of the trailing arms to keep if from hitting all the time) so I bought another set of standard disc spindles and installed them and used the beam adjustments to get the front just slightly lower than the rear. This fixed the too wide track, corrected the ride height and also eliminated the handling "quirk"! No more signs of the quirk - the car maintained the same neutral to slight unsersteer under all driving conditions after that. Never did figure out why it had the driving quirk with the dropped spindles.

In all it's glory (with the dropped spindles):

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Lowering For Handling

Look at the picture Chris posted of our `69 and visualize a line extending through the balljoint centers to the pavement - it's easy to see that it intersects the ground a couple of inches inboard of the tire tread centerline => positive scrub radius...great "feedback", but the wheel will be knocked out of your hands if a tire hits a big bump when you aren't prepared. Increases the steering effort at very low speeds, too.

You can also see that the tire has a noticeable amount of positive camber (it leans outward at the top) when at full lock. This is caused by the caster; the more there is, the more camber is gained as the wheel is steered off-center...a road-grader is a prime example, they have a ton of caster so there's lots of camber when they turn, done intentionally to make the tires lean into the turn for better grip in the dirt (the same idea is used for offroad rails, to help a light front end get some bite:

Next time you see a Mercedes-Benz parked with the wheels cranked, note how much camber it has - they use a lot of caster to improve high-speed straight-line stability on the Autobahn, without power steering it'd take a true he-man to parallel park one.

You can also see that the tire has a noticeable amount of positive camber (it leans outward at the top) when at full lock. This is caused by the caster; the more there is, the more camber is gained as the wheel is steered off-center...a road-grader is a prime example, they have a ton of caster so there's lots of camber when they turn, done intentionally to make the tires lean into the turn for better grip in the dirt (the same idea is used for offroad rails, to help a light front end get some bite:

Next time you see a Mercedes-Benz parked with the wheels cranked, note how much camber it has - they use a lot of caster to improve high-speed straight-line stability on the Autobahn, without power steering it'd take a true he-man to parallel park one.

- FJCamper

- Moderator

- Posts: 2901

- Joined: Wed Nov 14, 2007 2:19 pm

Re: Lowering For Handling

Above: 53 on a slalom course with too-high a rear roll center.

Hi GS,

We had a similiar experience with a too-low front on our 1970 road race Ghia. I installed a Puma axle, and it's highest ride height was 2" lower than stock. So with no rear suspension changes, we had a bit of a Cal-Look rake happening. We tried the car that way on race track test days and a slalom or two, and it was a handful. I had to disconnect the rear sway bar just to make it drivable at speed.

It didn't take much sleuthing to figure out that if you lower the front end too much relative to the rear that you have effectively "raised" the rear roll center. Oversteer comes and goes as speed and road surfaces change.

Going back to a stock front axle fixed all that. We lowered uniformly via 50-series tires, and all was well with the world.

FJC

-

Bruce2

- Posts: 7087

- Joined: Sat Oct 13, 2001 1:01 am

Re: Lowering For Handling

I think they are 11-12º.Marc wrote:Next time you see a Mercedes-Benz parked with the wheels cranked, note how much camber it has - they use a lot of caster to improve high-speed straight-line stability on the Autobahn,

-

Steve Arndt

- Posts: 7404

- Joined: Sat Mar 10, 2001 12:01 am

Re: Lowering For Handling

The new CB Puma beam has redesigned / positioned center adjusters so that it doesn't automatically start at 2" drop and go lower anymore. It also has more adjustment travel built in, and a sturdier adjuster blocks. I haven't installed it yet, but it looks like it will have plenty of space to index it back up to stock or higher.

Steve

My Baja Build

My Baja Build