I know some of your guys lower your cars for looks, and that is a catagory all by itself. To each his own. This subject is about lowering for handling.

Lowering changes lots of important suspension geometry that is not evident until something breaks or you crash the car.

A little lowering can be a good thing. It drops the center of gravity and makes the car handle better, and it reduces wind resistance for better top speed.

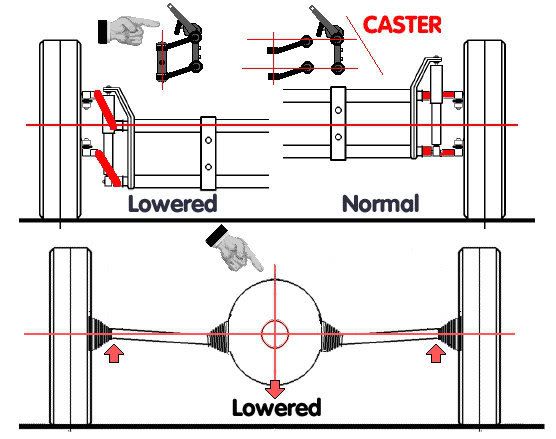

The affected front end geometry of a lowered Type 1 is caster (which makes you go straight), and bump steer (when the tires steer the car as they travel up or down).

The lowered rear end (on an IRS) begins to suffer axle angularity as the transaxle drops in relation to the centerline of the wheels. The axles are cocked upwards, adding stress (and robbing power at the CV joints) as they rotate.

How low should your rear end be? No more than what gives you straight axles at rest.

How low should your front end be? About two inches. Turns out that matches what will keep your axles straight in back, too.

Caster is easily misunderstood. It is just a slant. The bottom torsion bar tube on a Type 1 actually sticks out ahead of the upper tube just a little. At the front wheels, this creates the same condition as the casters you have on a shopping cart buggy or the front steering fork of a bicycle -- it makes the car tend to roll straight.

Lowering the front end, even in perfection with the rear, requires that caster shims be added under the bottom torsion tube, to jut the bottom tube out a little and add rolling stability.

At 100+ MPH this means the difference between life and death.

The other front-end lowering gotcha is bump steer. Remember, your steering tie rods are of a fixed length, and as the suspension moves up and down, the only compensation is the ball-joint pivot of the tie-rod end.

When the suspension travel is at such an extreme angle that the tie rod's ability to pivot is reached, the tie rod then either pushes outward or pulls inward on the steering knuckle, and the car becomes self-steering.

This is very, very dangerous at normal highway speeds. At racing speed, it can cause crash and burn spectaculars.

There is not much you can do about bump steer except not lower to such extremes that it becomes a problem.

Lower with care, and it'll help you go faster and win.

FJC