I received my parts from Subarugears a while back and am just now getting a chance to install them into my transmission. If you are getting into doing the actual work of opening up your transmission I'll assume youve watched all the videos that Subaru gears has to offer on the subject. This post is intended to fill in some of the missing details.

So I opened up the other side of the front differential housing to accept the ring gear as detail in the videos on their website/youtube and nothing unusual to report on the 6speed vs 5speed process. Then I moved onto the pinion change over which instantly i notice would be a bit different than the documented 5speed install. Mainly beeing that since it has an extra gear, It's decently longer than the 5 speed. Then I could see that the lock nut is a bit different than the 5 speed and not a easy to remove at 100ft/lbs and not a lot to hold onto to remove it without having the factory holding tools to stick it in your vice. But the first real issure i ran into after reassembling the pinion inside the driven gear tube. There is a slight length discrepency between the oem pinion and the new Subarugears one. Hard to tell with the blind eye but i could see around a .020" gain in length on the new part. This turned into a problem when trying to tighten the lock nut on the pinion to snug up all the thrust bearings and get everything tight with not play which would cause your end play measurements to be all over the place.

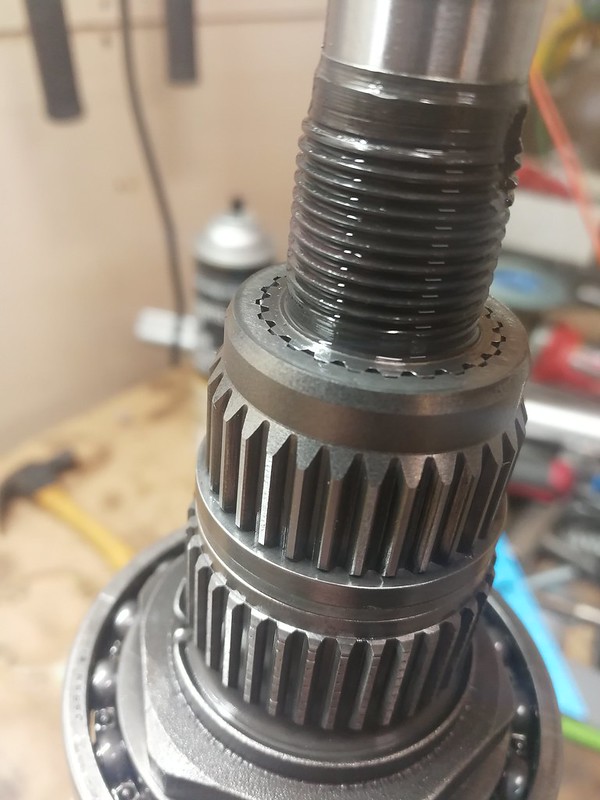

Here is a pic of the factory fitment excluding the two washers and nut on the very end of the stack seen in the following picture from the FSM.

IMG_20191007_140535 by Travis L, on Flickr

IMG_20191007_140535 by Travis L, on Flickr wrx trans by Travis L, on Flickr

wrx trans by Travis L, on FlickrAfter reading through the FSM, it stated that the splined collar should "visually be flush" to the top of the splines. and as you can see, it is indeed pretty close to flush. Though on the new part in the following picture, the splines are proud about .015" as previously seen on a shitty tape measure.

IMG_20191007_142315 by Travis L, on Flickr

IMG_20191007_142315 by Travis L, on Flickr