So I have a project of turbocharging a 2 liters engine from a 914. Of course, I read everywhere that Wally did it with impressive results, but I actually couldn't find the pages about the build, so I decided to get a topic started here.

The specs will be as follow:

- Stock crank

- 228mm flywheel

- Stock rods

- Stock 94mm piston/ cylinders, with stock rings

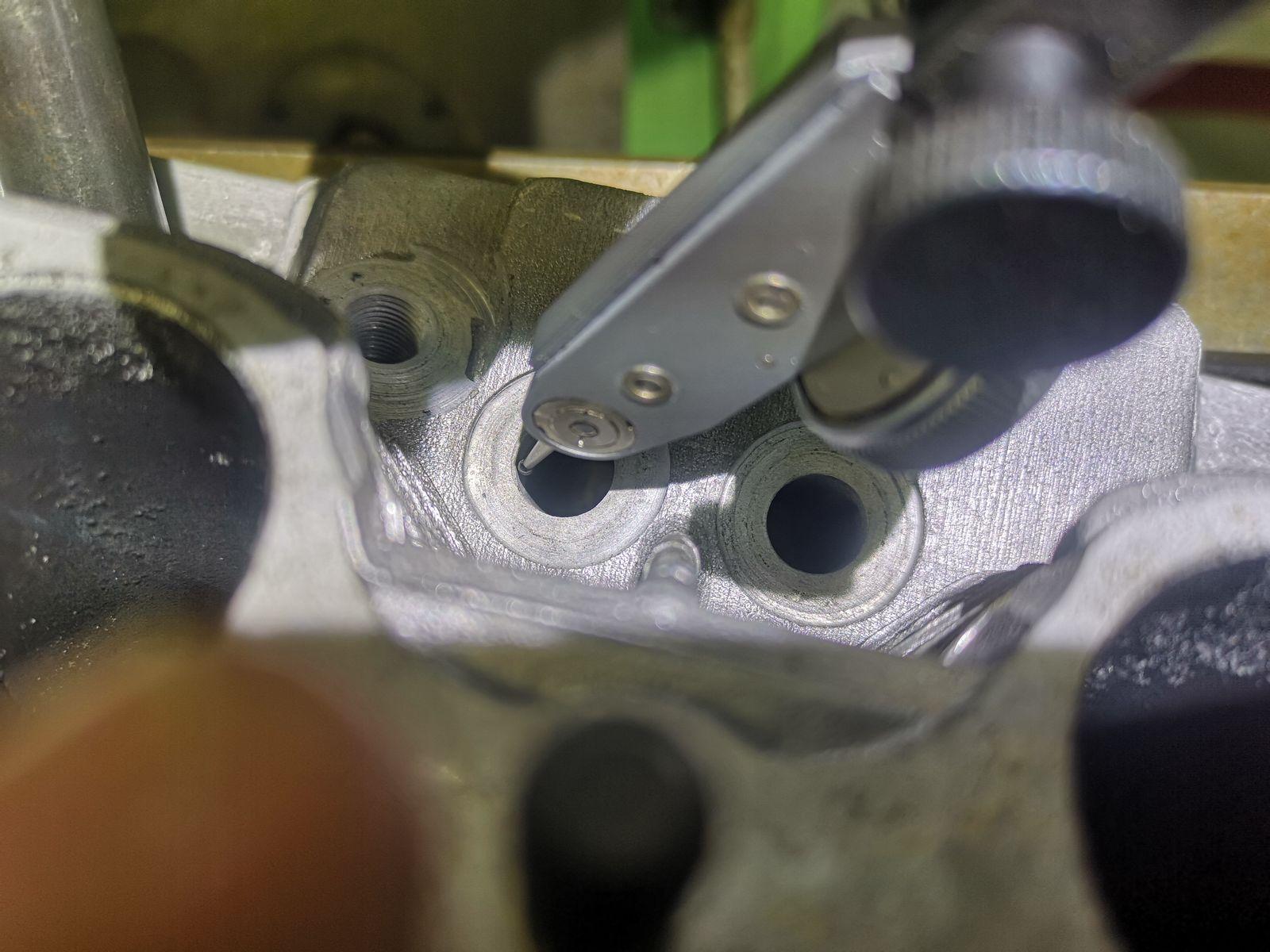

- Stock 3 bold heads, they are not cracked but they require work

- Type 1 lifters

- Webcam camshaft

- Original cooling, since the engine will go in a type 34

I need your opinion about a few things:

- I am considering updating my heads to decrease the plug diameter and increase the valve seats at the exhaust to install 38mm valves, do you think that it will be useful? Does anyone have adresses in Europe for that?

- Can I keep the stock rods? mine have the 2 liters 50mm

- Should I change for some forged pistons, I have type 1 Wiseco on the shelf, will have to check if they are compatible

- Would you update the stock rings? I couldn't find something really exciting online