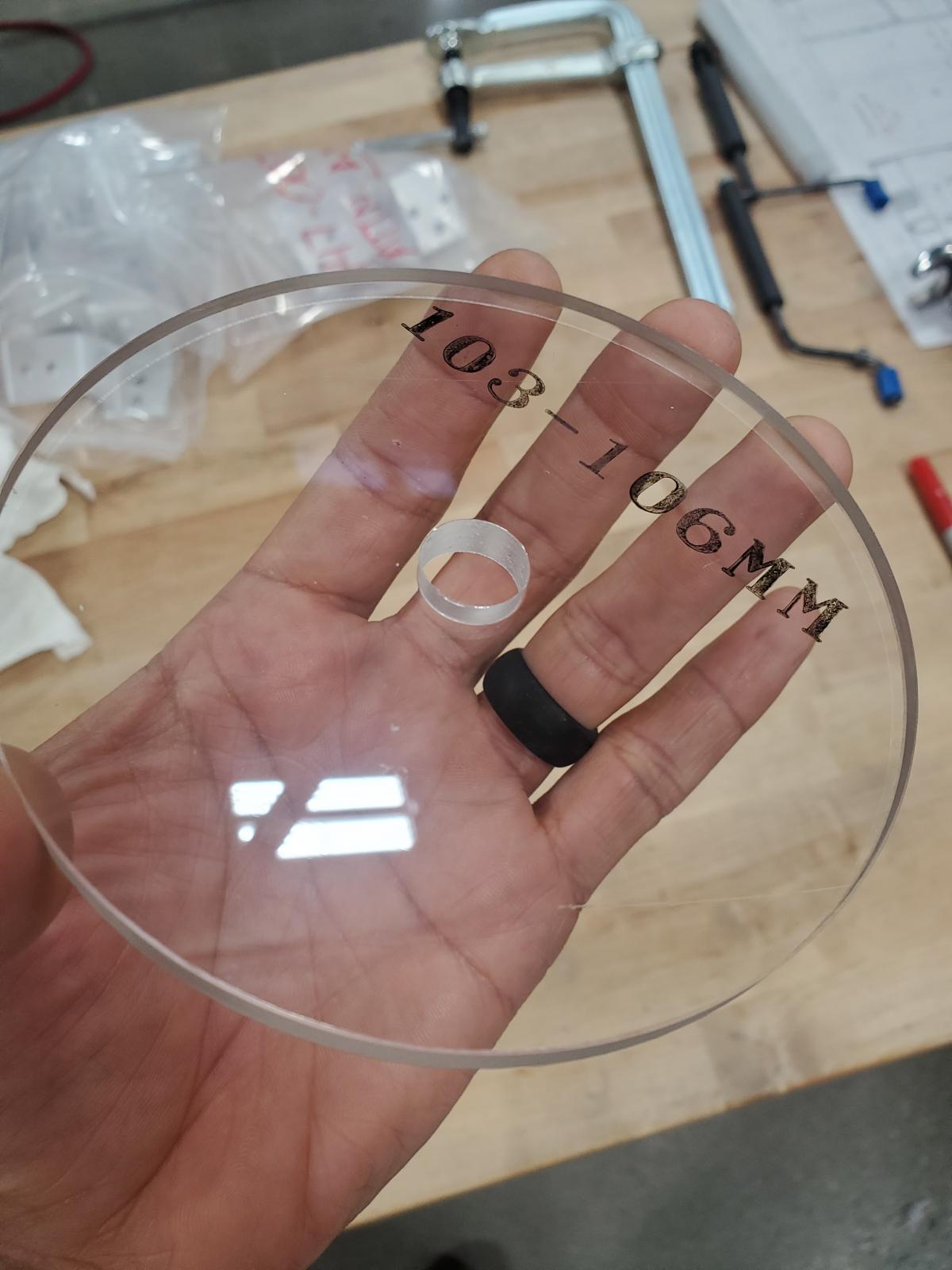

Made some chamber volume plates. I knocked out a few for the future. My 66x105 will need one, and I made one for the 36hp platform.

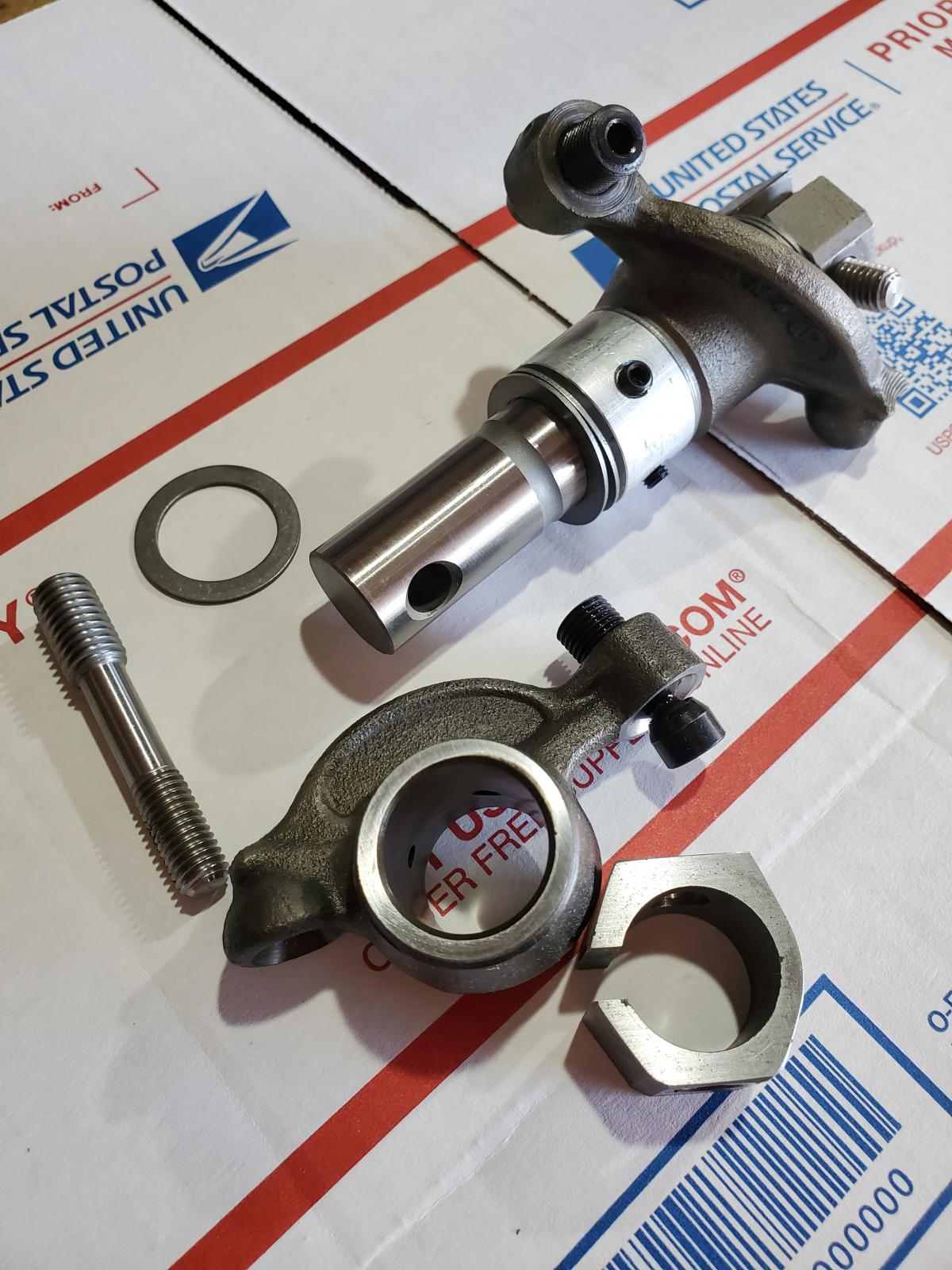

Sent these bad boys out to a 914 owner in Florida: Chromoly shafts, high strength 8mm studs, machined and resurfaced rockers, tool steel adjusters, spring steel shim varieties, pinned solid spacers, and narrowed mounting blocks.

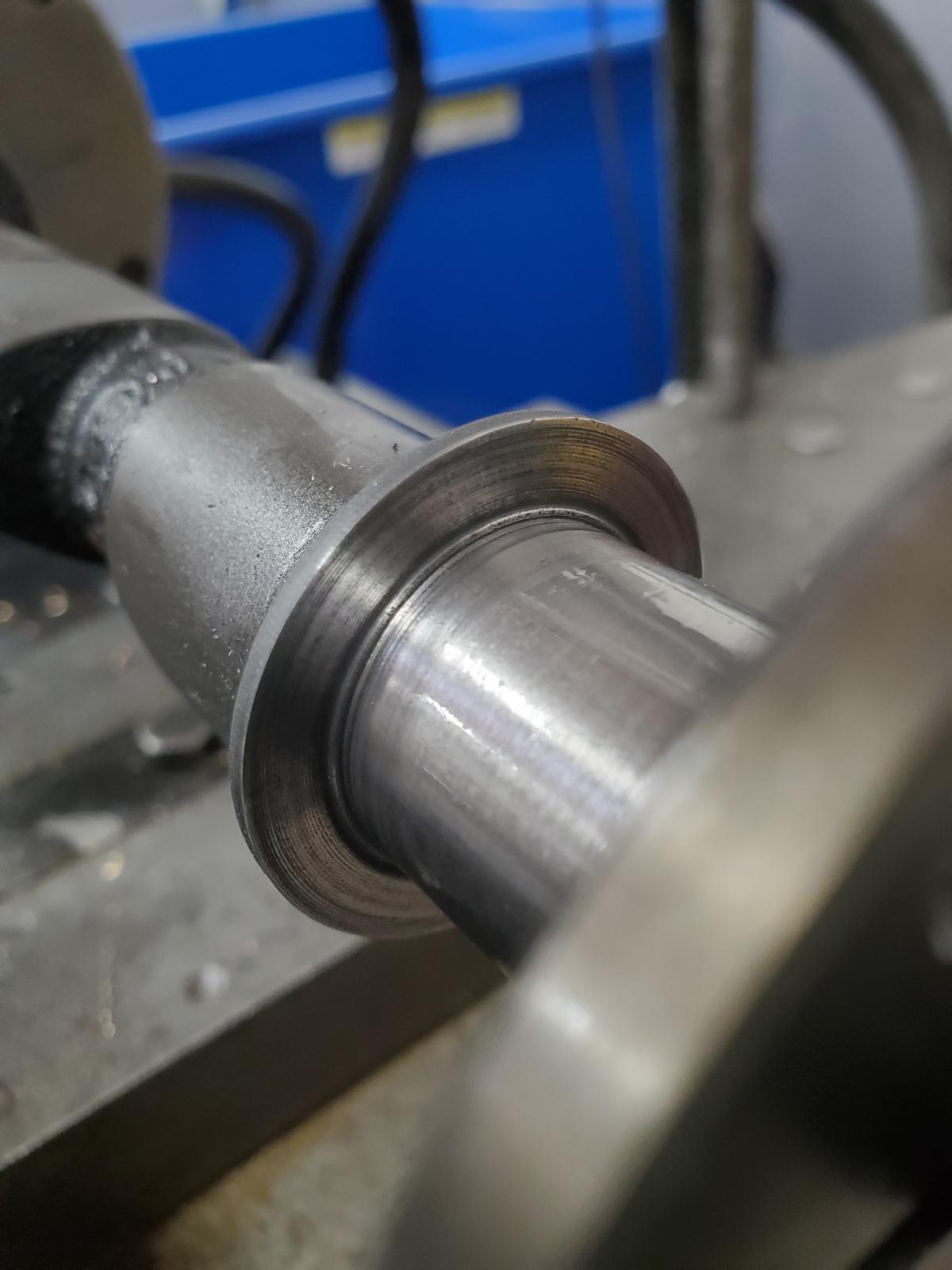

A friend sent me these oversized shafts (left) as a gift for worn rockers. You can hone them and still be within radial spec. Centerless-ground, smaller mounting holes. The right ones are standard chromoly shafts.