F.Y.I. cheap intercooler cores can be bought from the likes of Ebay and are normally from modern passenger cars. I normally go for brand new intercoolers as they are nice and clean. They can be bought very cheaply: normally less than one fifth of the factory price if it’s a stock clearout! A good line of intercoolers to go for come from the V.A.G. Group such as VW and Audi as their cores tend to be of a good size. Audi TDI motors are normally a good source.

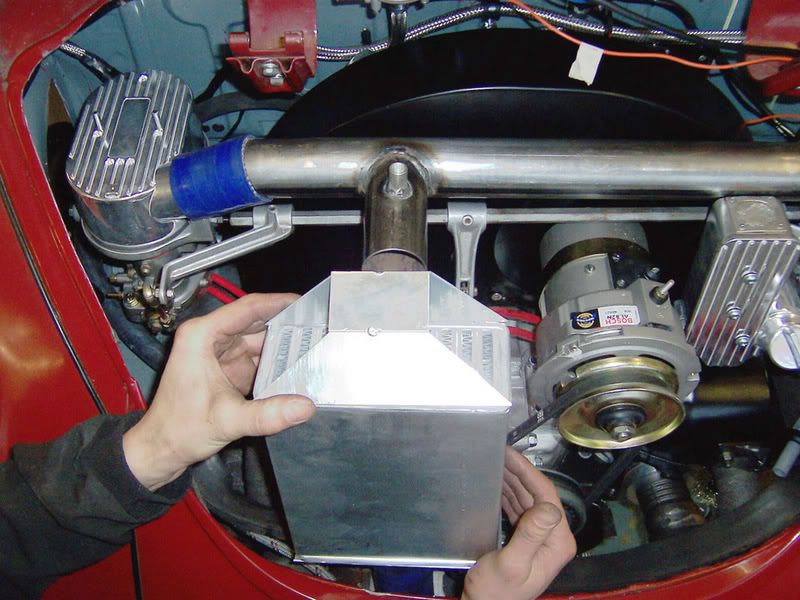

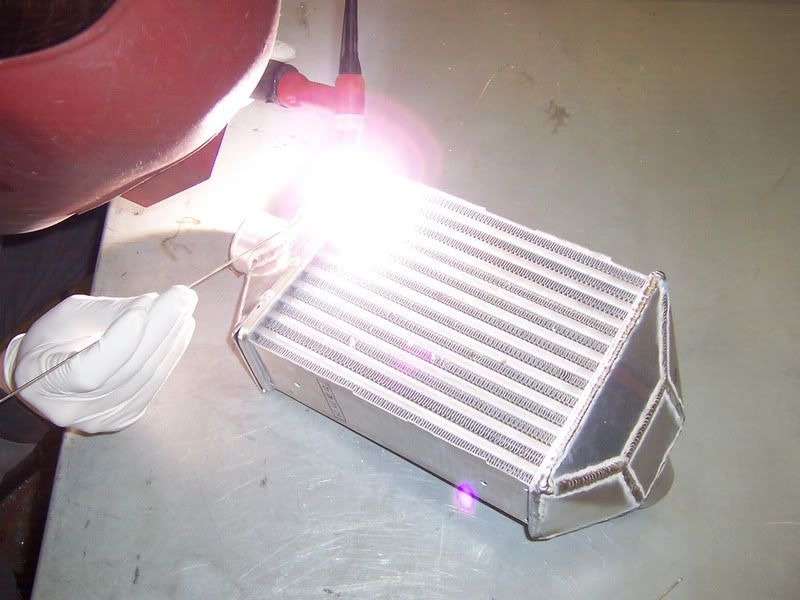

Here’s a shot of a finished chargecooler installation done a couple of years ago. I used an Audi TDI core and, a home made header tank, an oil cooler (for cooling the water) and a Golf VR6 electric water pump. Total cost not much more than $200 or £100.

The beauty of this system is that it fits under the stock decklid of a stock Bug without stand-offs.

All water connections were 19mm (3/4 inch). Pump flow was 12 litres a minute.

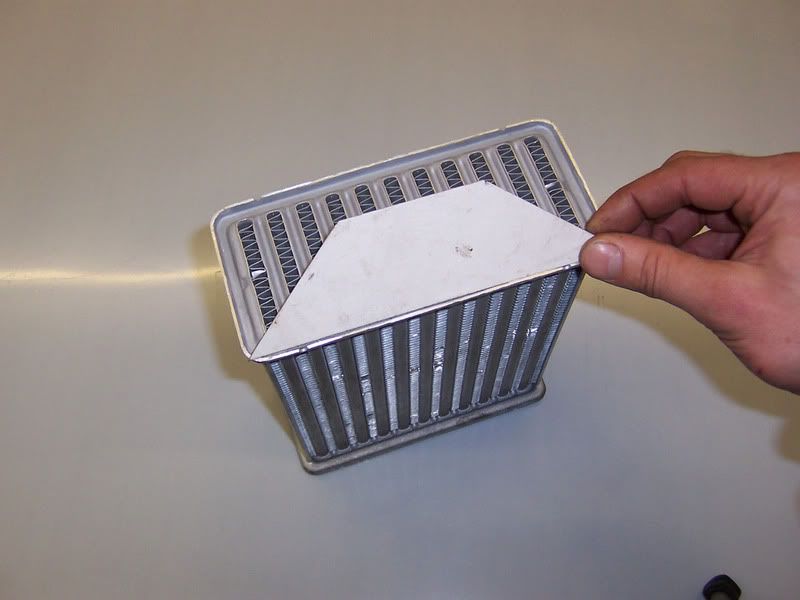

The first task is to work out how much space you have and find a suitable core. You need to have a good air flow through the core. The one pictured above easily handled 250 hp on the rolling road. Most VAG intercoolers come with plastic end tanks crimped on to the core. These are very simple to work with.

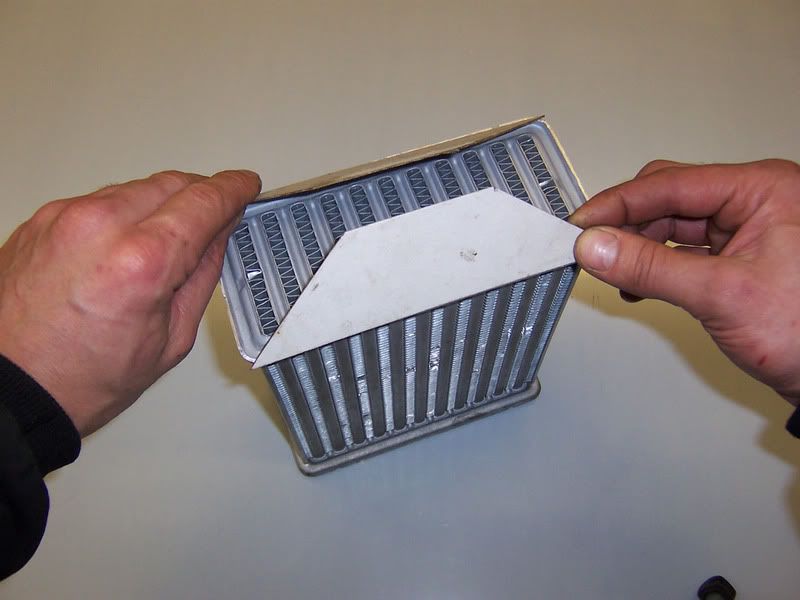

To remove the end tanks it is simply a case of loosening off the crimped over tags with a screwdriver

mark a nice straight datum line

Next I cut a straight line using tinsnips. You need a good straight edge here.

File the edge flat to make absolutely sure

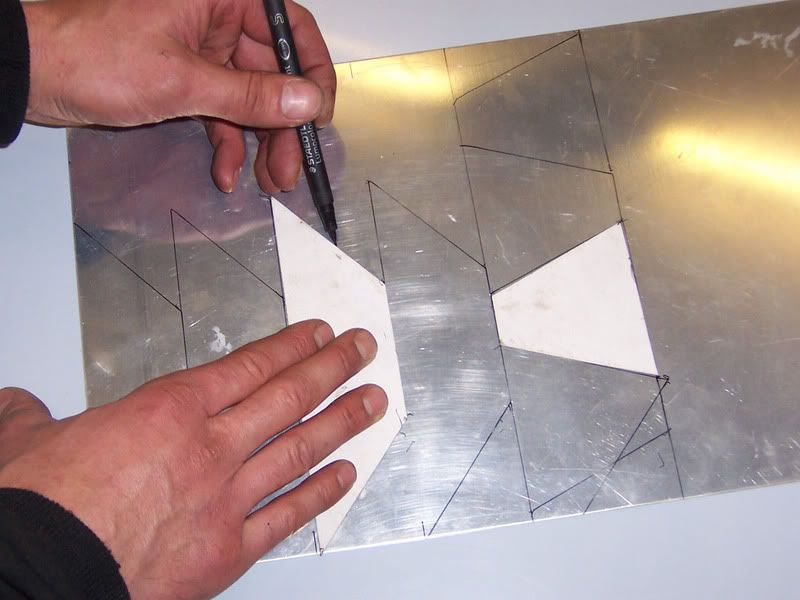

Next I start working with pattern development seeing what will work beneath the decklid. I aim for good flow paths to minimise friction.

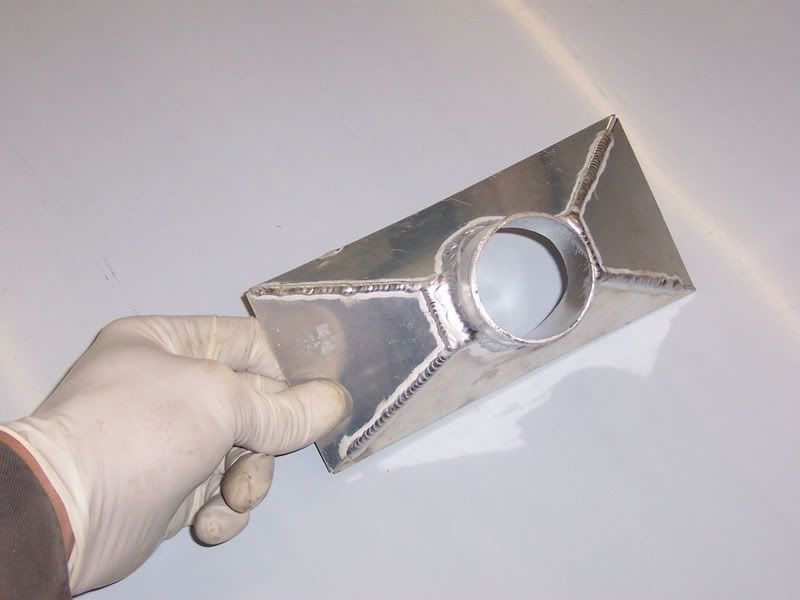

I then Tig Weld up the aluminium to form the end tanks and drill a hole through for straight tubing.

I then tack weld the end tanks to the intercooler core and check all still fits under the decklid.

When I am fully happy the shapes work and there are no clearance issues I then fully weld up the intercooler end tanks.

Time to make the water jacket using ali sheet metal. Simply fold up a U-section and cut one flat piece of sheet metal.

Fully weld the sheet metal to your intercooler end tanks and then pressure test to at least 20 psi with a tyre pressure gauge. Submerse the intercooler in water and check for any leaks. Any leaks must be dealt with or it will all end in tears...

I then work out where I want my water connections. The water IN needs to be at the BOTTOM of the core and the water OUT needs to be at the TOP on the OPPOSITE side of the cooler to help expell any trapped air and ensure water flow through the cooling fins. The system needs to bleed fully for proper operation. Any air in the chargecooler will render the system inoperative in terms of water flow. The pump will sit there humming all day long cavitating!

Finally a shot of the home made header tank, VR6 electric water pump (thanks to Marco Mansi for the tip

For your information... this chargecooler setup was tested on the rolling road and the car made 239 hp @ 15 psi of boost. Motor was a 2007cc unit with TCS 20 cam, 48 Turbo Dells and 42x37.5 044s.

During the power runs the intercooler outlet temps were monitored and using a 15C cooling water the outlet air temps stabilised at 28C. Not bad considering the inlet temps into the intercooler were 100C! It works