I find the velocity stack to be one of the most misunderstood pieces of tuning equipment. That's probably because good info on them is lacking. All the average tuner sees is ads that sell them.

First, VS are not for looks. They correct an airflow problem non-plenum carbs have at certain engine speeds.

A "plenum" is just a space or area. V8 builders have a plenum area under their big 4bbl carb manifolds. The plenum space allows a common area from which the cylinders draw an air fuel charge, and the plenum acts as a cushion to dampen the violent reversals of air velocity that occur between the carb throat and the intake valve.

Yep. The air coming into a carb and intake manifold is not just on a one-way trip. The intake valve slams shut as the air is flowing, and a shock wave created by the sudden halting of flow shoots straight back up the manifold into the carb. The force of this "reversion" can be made worse by some cams.

A plenum design gives that shock wave a place to dissipate.

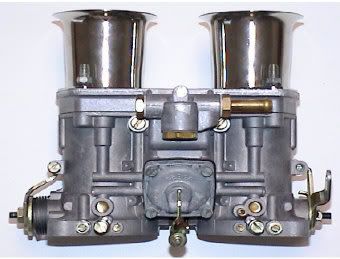

Plenum designs are much easier to tune than nonplenum systems, which covers the Weber, Dellorto, and similar designs.

The disadvantage of the plenum system is it is not as tunable as the Weber type system.

Webers are forced to have velocity stacks, because at certain RPM ranges, the return shock wave from the intake valve literally forces air/fuel out of the top of the carb. The velocity stack (sort of a misnomer) is just an extension of the carb to contain that air/fuel revulsion.

If there is no VS, the air/fuel mix gets messed up, and a carb fire is a good possibility with aerated gas now being ejected into the engine compartment. Just let a high-rev valve float on an intake valve allow a manifold backfire ... and this is why many old time Weber tuners think of air filters as fire safety devices ... flame arrestors.

VS stack height is related to manifold lengtht.

Race tuners know there is a specific length from the carb mouth to the intake valve that produces the best power at a specific RPM. For racing, you can change this by just changing VS!

For the street, you have to compromise. The short Weber manifolds most kits have work just fine with the appox 3" high VS in the same kit. For variable RPM road racing, a 1.6 engine redlined at 6000 needs about a 16" runner length, meaning the total measurement from carb mouth to intake valve.

Shorter runners lengths give more power at high RPMS, longer lengths give more power at lower RPM's.

By the way, the Solex carb design sold by Kadron is a plenum type and needs no VS, even though you can buy them. And, a last oddity between plenum and non-plenum carbs is there is no direct comparison between performance and venturi sizes.

Plenum carbs don't need the same size venturis as non-plenums to give equal performance.

FJC