External Oil Filter hookup

http://www.shoptalkforums.com/viewtopic ... 24eca1025d

Too much oil pressure-blowing filter seal why?

http://www.shoptalkforums.com/viewtopic ... 3ae265d64e

turboblue wrote:This is a visual of what SpazMO is saying.

The older I get the more I need pictures and I borrowed this engine case picture from TOS.

I sucked in high school art class so bear with me.......

Red line represents oil path when it is hot and the viscosity has thinned somewhat.

Light blue line represents the oil coming from the cooler down to where it intersects that plug between 3-4.

Bearings, lifter bores, etc fed from that point

Dark blue line represents the oil path when cold.

Bypasses cooler and intersects that same plug and then feeds the above mentioned parts.

Yellow is plunger/spring for oil cooler bypass.

Green is oil pressure relief. Dumps excess back to case sump.

Accumulator should still see pressure but it would be backfed when the oil is cold.If there is a thermostat kinda plunger that bypasses the oil cooler, that could be a problem.

However, I would expect pressure to still build in the oil cooler.

As soon as I get that schematic I'll post it up..........

RyanB wrote:

I got the replacement from FOA. Then to be sure I went out and purchased a new pump that directs the oil outside like a full flow system. I went out of the pump into an oil filter, then up to a T that the Oil Accumulator is connected to. Then through an oil cooler and down back to the return line to the rest of the system.

Here is a diagram:

Keep in mind this is all EXTERNAL except for the pump of course. The oil cooler and accumulator sit on the back of the buggy.

Sadly, I havent been able to get back to this. I got it all setup and tested it quickly and noticed I wasnt getting additional pressure like I should be on the air side of the accumulator. I didnt have time to look into it and left the buggy at home and went to sand lake. Then I had a tree that tried to kill me when I was on my Quad. Ended up breaking a couple ribs and I ahvent been able to get back out to the garage since. Doc says I cant do anything strenuous for another 6-8 weeks...

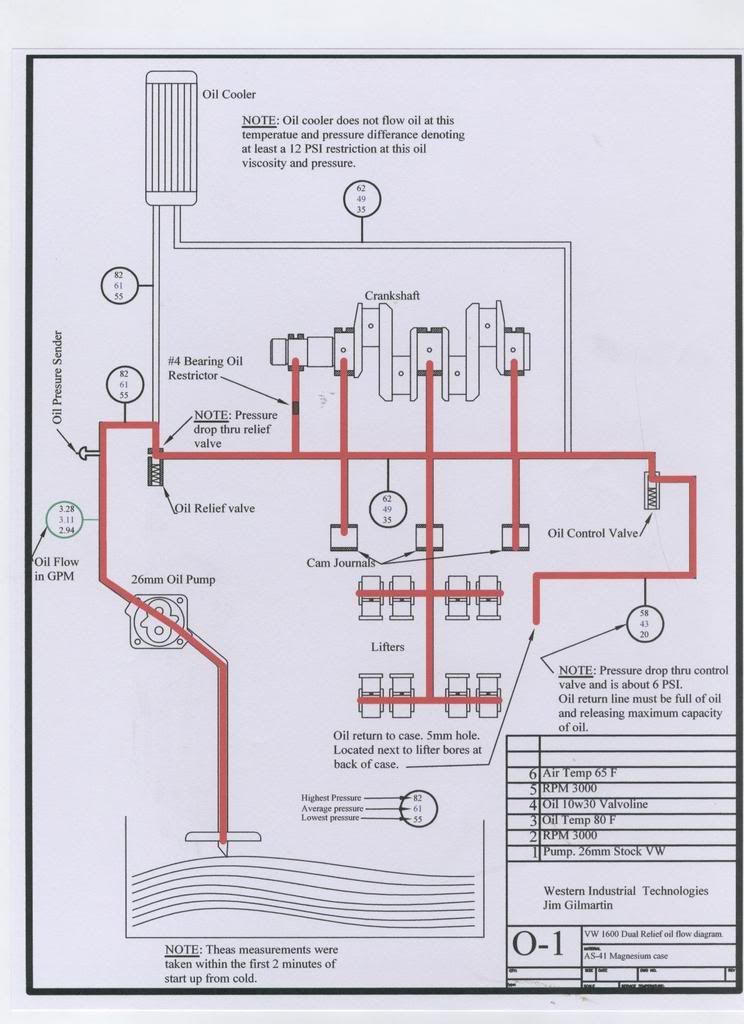

Jimmy111 wrote:A lot of people dont seem to understand how the Oiling system works So I will try to explain it with drawings and tests that I did years ago. We tested 100 VW stock dual relief motors.

All motors were diaasembled, cleaned and had cranks reground and new bearings installed to spec.

The same oil pump was used in each motor.

The same oil cooler was used on each motor.

All the cases were line bored, full flowed and a flow meter was installed in the loop from the pump to the case.

This first drawing is the oil flow and pressures when cold with a oil temperature at 80 F.

There was a wide variety of pressures and flows recorded and I will explain the findings when I come to them.

I will add new drawings as I transfer the data to the drawings.

Next drawing.

This is the flows and pressures at 120 F oil trmperature. At this point oil is just starting to flow thru the oil cooler.

Next drawing.

Here you see the motors are at operating temps, 180F Everything should be fine but the relief valve is still open. We kept running the motors and most of them reached 225 before we shut them off and most of the relief valves never closed.the relief valves never closed. The motors never went over 225 either. All the excess oil is still running out the control valve. It is open 100%. I will explain this in another drawing.

Next drawing.

Here are the motors at Idle. Notice that the relief valve has closed and the control valve is closed. All the oil is now flowing thru the oil cooler.

Next Drawing.

This is again up to 3000 RPM after Idle at 190F

Notice now the relief valve is closed and the control valve is open.

All the oil is flowing thru the cooler and a lot of oil is flowing out the control valve. Interesting aspect of the relief valve and is that it opens at a much higher pressure than it closes at. Ill explain that in another drawing.

Next drawing. Here is where we started having problems.

30mm pumps.

Notice the high pressures. There were 6 motors that reached that pressure due to different reasons. We lost 6 oil coolers at this point. Had to find the problems and retest all 6. Today this would show up as blown oil filters too.

Notice the increase in oil volumn. . This extra oil has nowhere to go because the oil relief hole is too small. that is why the pressure increases so much.

Here is 120F notice how no oil flow thru the cooler. Pressures are equal everywhere.

Here is 190F The oil is flowing thru the cooler but the relief valve does not close due to the high pressure.

Here the motor goes back to Idle and still the pressure is too high to close the valve.

Here is a section of the oil control valve Notice the opening and closing pressures of the piston.

This is the plug that needs to be removed and drilled.

Oil Flow restrictor. I will update this later.