Project---Split cable pull linkage

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Project---Split cable pull linkage

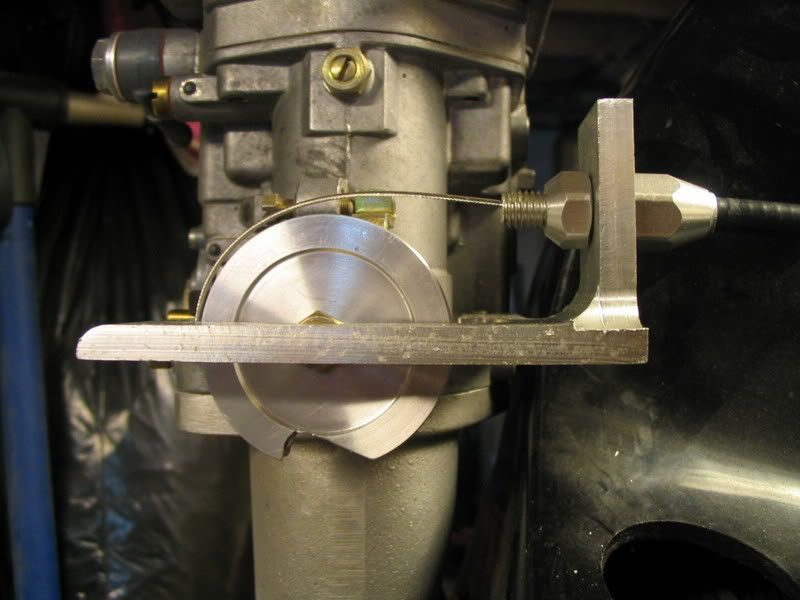

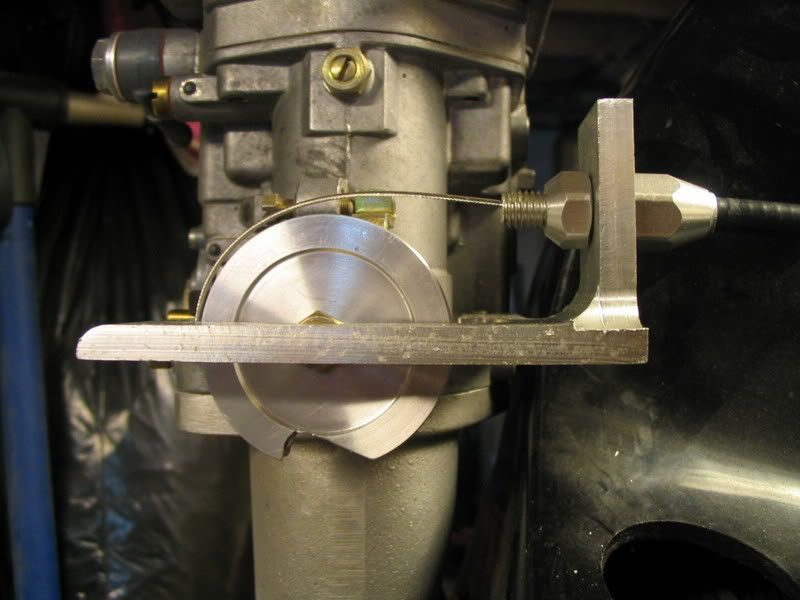

These are some pics of the linkage I made up back when I ran carbs.

I originally bought a CB Hexbar + air cleaners--- Took the hexbar off after about a month of fighting with the accel pumps squirting gas all the time.

This cured that issue completely, and worked much better overall.

Some further discussion here:

http://www.shoptalkforums.com/viewtopic.php?t=109017

These pics are old ones, and not wonderful.

This is actually the second iteration of this, as I lost some of the bits when the motor was in my sons bug as an upright conversion when he had cam+lifter issues...

The original setup just pulled on tweeked std Weber throttle bits... I think I salvaged them off Progressives, which are ~useless otherwise IMHO.

If I had more than an hour or so and $20 in this I'd be shocked.

I only ever had to adjust this setup once after installing the steel carb side brackets. It stayed in sync perfectly for ~50K miles, including once when I pulled the carbs to clean them... Pulled cables tight and clamped on pulleys, checked perfect on the Snail. Took seconds to hook back up.

A CIS install on otherwise std L-Jet plumbing replaced the IDFs after that.

One of the nice things about this setup is that if you have a Baja or such with access to the front of the motor, this can just as easily go up front, out of harms way (and almost invisible)

It should also be easily sealed for dirty conditions...

The first 3 are pretty self explanatory, perhaps a bit fuzzy...

This is off a Yamaha 4...??? Aluminum tube body, nylon piston.

Bicycle brake cables go to carbs...

The top half is actually a cut down T4 pushrod, tapped on one end for the 914 std throttle cable, bottom drilled and flared for a snug fit on the actual splitter... The threaded bit of the cable gets cut off, and a cable crimp from Home Depot pulls on the piston. (collet w/setscrew might work too)

(recent edits due to re-adding pictures lost to the bitworms)

I originally bought a CB Hexbar + air cleaners--- Took the hexbar off after about a month of fighting with the accel pumps squirting gas all the time.

This cured that issue completely, and worked much better overall.

Some further discussion here:

http://www.shoptalkforums.com/viewtopic.php?t=109017

These pics are old ones, and not wonderful.

This is actually the second iteration of this, as I lost some of the bits when the motor was in my sons bug as an upright conversion when he had cam+lifter issues...

The original setup just pulled on tweeked std Weber throttle bits... I think I salvaged them off Progressives, which are ~useless otherwise IMHO.

If I had more than an hour or so and $20 in this I'd be shocked.

I only ever had to adjust this setup once after installing the steel carb side brackets. It stayed in sync perfectly for ~50K miles, including once when I pulled the carbs to clean them... Pulled cables tight and clamped on pulleys, checked perfect on the Snail. Took seconds to hook back up.

A CIS install on otherwise std L-Jet plumbing replaced the IDFs after that.

One of the nice things about this setup is that if you have a Baja or such with access to the front of the motor, this can just as easily go up front, out of harms way (and almost invisible)

It should also be easily sealed for dirty conditions...

The first 3 are pretty self explanatory, perhaps a bit fuzzy...

This is off a Yamaha 4...??? Aluminum tube body, nylon piston.

Bicycle brake cables go to carbs...

The top half is actually a cut down T4 pushrod, tapped on one end for the 914 std throttle cable, bottom drilled and flared for a snug fit on the actual splitter... The threaded bit of the cable gets cut off, and a cable crimp from Home Depot pulls on the piston. (collet w/setscrew might work too)

(recent edits due to re-adding pictures lost to the bitworms)

You do not have the required permissions to view the files attached to this post.

Last edited by Piledriver on Sat Sep 21, 2013 9:44 pm, edited 5 times in total.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

- jonas_linder

- Posts: 1587

- Joined: Sun Sep 08, 2002 12:01 am

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

slowtwitch wrote:Pile , thanks for the pics. I'm working on a similar project. Hopefully, I'll finish it up this weekend. When i get done, I'll post pics of what I have. Hey !!! should we be patenting this stuff???

pete

I rather doubt it's patentable, as it pretty much falls under "bloody obvious" and that style linkage has probably been used for 100 years on various vehicles..

Someone company should make them though.

Works so well...

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

BajaPorsche

- Posts: 320

- Joined: Sun Feb 20, 2005 2:40 pm

DO the pulleys have to be specially machined? that's a nice application!

Piledriver... maybe you should take the foto's down to the post office, with an envelope, have the PO stamp the fotos and then stamp the envelope, and mail it to yourself...... I'm thinking alot of guys might want this....

if it was so bloody obvious, someone would have completed this thought -- long ago! I've been thinking about it, but just never put the thought together......

Again, did you have to machine special pulleys, or was it something bloody obvious that worked..............that I just can't figure out?

Piledriver... maybe you should take the foto's down to the post office, with an envelope, have the PO stamp the fotos and then stamp the envelope, and mail it to yourself...... I'm thinking alot of guys might want this....

if it was so bloody obvious, someone would have completed this thought -- long ago! I've been thinking about it, but just never put the thought together......

Again, did you have to machine special pulleys, or was it something bloody obvious that worked..............that I just can't figure out?

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

If anyone wants to make a professional version of this, I hereby release it... fully. Knock yourself out.

If you _like_, send me a few kits. Give appropriate credit if it's decent.

*****************

I made the pulleys after work from scrap.

Took 2 iterations...

(I looked for off the shelf pulleys at Home Depot, but as I actually HAVE a set now, I can have a look in the McMaster-Carr or Grainger catalogs etc for something close...

I would make some detail changes if I made another set, but it's trivial stuff.

The pulley diameter I used worked well on a 914, I think a bug app would have them a tad smaller, as IIRC the pedal throw is less.

If you _like_, send me a few kits. Give appropriate credit if it's decent.

*****************

I made the pulleys after work from scrap.

Took 2 iterations...

(I looked for off the shelf pulleys at Home Depot, but as I actually HAVE a set now, I can have a look in the McMaster-Carr or Grainger catalogs etc for something close...

I would make some detail changes if I made another set, but it's trivial stuff.

The pulley diameter I used worked well on a 914, I think a bug app would have them a tad smaller, as IIRC the pedal throw is less.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- jonas_linder

- Posts: 1587

- Joined: Sun Sep 08, 2002 12:01 am

-

BajaPorsche

- Posts: 320

- Joined: Sun Feb 20, 2005 2:40 pm

Piledriver.... how much would you charge to make me 1 set of the pulleys.... I'll look around home depot and through some granger catalogs.......... but i'm thinking the center hole, where it attaches to the throttlesahft, has got be something that won't slip, the flat on one side type...... did you machine your pulleys with a round center hole, or did you machine something that slipped on tight?

I have a proto type air filter housing for the fuel injection, that i have painted black with a clearcoat over it.......... acrylic auto paint, with the plastic adhesion prior to paint.... just like painting the plastic bumpers........ IF you want to test it out for me.... see how it holds up, I'm willing to trade it for a set of pulleys.

I'll get some foto's up if you're interested.

I have a proto type air filter housing for the fuel injection, that i have painted black with a clearcoat over it.......... acrylic auto paint, with the plastic adhesion prior to paint.... just like painting the plastic bumpers........ IF you want to test it out for me.... see how it holds up, I'm willing to trade it for a set of pulleys.

I'll get some foto's up if you're interested.

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

Well, here are some pics of my cable linkage. Since I have a DTM, clearances are tight between the shroud and carbs.

I had to figure another way to mount the cable bracket. This is what I came up with, still in it's ruff stage

I'm working on the center pull now. It will be a center pulley, with adjustments for cable length. Hopefully, I'll be done this week. Then I have to learn how to anodize this parts

pete

I had to figure another way to mount the cable bracket. This is what I came up with, still in it's ruff stage

I'm working on the center pull now. It will be a center pulley, with adjustments for cable length. Hopefully, I'll be done this week. Then I have to learn how to anodize this parts

pete

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

That's what I'm talking about!

I was going to do the "flat" thing on the center hole, but it proved not to be a bug, but a feature.

You could put the pulley on, leave the nut just a hair loose (just snug) and open/close the throttle, taking the slack out of the cable...

Tighten nut.. Perfectly set cable length.

Never had issues with them loosening up either.

(Used the thin wavy lockwashers)

The "notch" thing o the pullet for the wire end works great if you can get the right length cables... I suppose a small ferrule crimped on would work there too!

I was going to do the "flat" thing on the center hole, but it proved not to be a bug, but a feature.

You could put the pulley on, leave the nut just a hair loose (just snug) and open/close the throttle, taking the slack out of the cable...

Tighten nut.. Perfectly set cable length.

Never had issues with them loosening up either.

(Used the thin wavy lockwashers)

The "notch" thing o the pullet for the wire end works great if you can get the right length cables... I suppose a small ferrule crimped on would work there too!

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

BajaPorsche

- Posts: 320

- Joined: Sun Feb 20, 2005 2:40 pm

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Based on that pic, my setup would probably clear a DTM OK, but I really like Slowtwitches setup too. (really HD and easy to mount a dirt/brushguard or such)BajaPorsche wrote:OK, I'm following you piledriver......... you snugged up the cable at the pulley, by rotating the pulley, then tightend the pulley nut....... did you just have the throttleplates closing as the stop for full throttle?

The design of my setup was a matter of what material I had at hand, I had some 1" aluminum angle scrap, a sawzal, a drill, and some MC throttle linkage bits, bicycle brake cables from Wally World...

(Necessity is the mother of invention and all that)

There are adjustable stops on the carbs... Should be set to match with the snail flowmeter. The "open" stops are fixed.

(perhaps I'm completely missing the question here...)

I had to jack with the diameter of the pulley and pedal to get the right throw to get WOT. (The 914 has an adjustable gas pedal end linkage)

That's why I had to make 2 sets. The original//smaller ones were ~ for a bug, but I have NO clue where they went.

The throttle arm lever on my 914/CIS rig NOW is the same diameter pulley...

The original Bus throttle lever went the wrong way, so I fabbed a setup for that, too.

Slowtwitchs center pulley idea could be set up with 2 sets of holes for rate, or be made adjustable w/ a sliding throttle cable input pivot point.

(more complicated one way, less in others)

An adjustable stop in the linear splitter might be easy to do... to set the travel.

These pulleys go OVER the factory stop bit... or it's on the other end. (They go over something I hooked the return springs to...)

Pulley's pretty thin in the middle.

I'll make some measurements/pics and send them to you, but they MIGHT be too large for a Bug w/o modding something for more travel.

PM me.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.