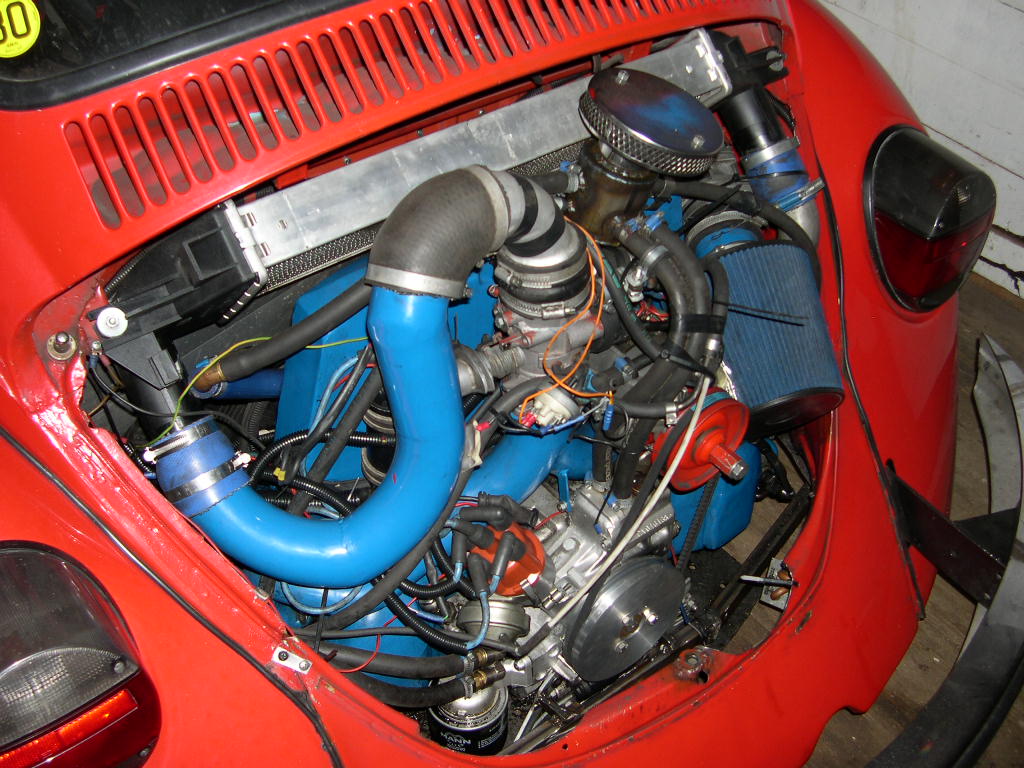

Nice to see my old 1303

type 4 turbo as usual

Tried something fun yesterday. People always say that aluminium is soo hard to weld, but...how hard can it be? jonas Linder gave me some welding sticks and i had to try them out on a old cracked head..

the thought was to build up some aluminium on the inside of the exhaustport to be able to get the curve smooother for the exhausts.

First i started with grinding out the port to get rid of the carbon and dirt.

Then i just welded in the port:D

It was mutch easier than i had ever imagined

then i grinded the port to it´s new shape, hard to see in a picture but it really feels better;)

Ok, i know i should have preheated the heads, and there is probably more things i did wrong.. but this was just for learning:)

I tried to do a reinforcement to the head just for fun. I didn´t cleaned the head at all at this spot, just welded an d it seemed to work fine

Someday i´ll do some work on my real heads;)