EDIS rpm issue, rpm reads high

-

fugazi885

- Posts: 13

- Joined: Mon Dec 30, 2013 2:35 pm

EDIS rpm issue, rpm reads high

So I just got my new engine fired on megasquirt, msII 3.57 board running EDIS with a hidden crank trigger from the dub shop. It starts pretty easy most of the time but sometimes the tach signal acts up and reads 2500 to 3000 rpm when the engine is barely running. I can look at in tunerstudio and it's timing and fueling for the higher engine speed but barely running over idle speed. Seems to last maybe 20 or 30 seconds when it does it and then just smooths out and runs smooth as silk, also only does it just after starting. I haven't driven it farther than down the block but it seems like once it decides it likes the signal it stops acting up. From what I have read so far it doesn't seem like the trim pots should need adjustment since it's EDIS. Anyone else experience anything like this?

-

miniman82

- Posts: 3944

- Joined: Sun Apr 27, 2008 3:36 pm

Re: EDIS rpm issue, rpm reads high

Sounds like noise, do you have the PIP and SAW wires properly shielded?

-

fugazi885

- Posts: 13

- Joined: Mon Dec 30, 2013 2:35 pm

Re: EDIS rpm issue, rpm reads high

I did not shield the pip and saw wires, only the vr is shielded at pin 7 on the EDIS module. Should the pip and saw be shielded to pin 7 as well or should the shield wire be grounded? I also rechecked the sensor air gap. The instructions that came with my pulley and sensor specifies a 2mm air gap but from what I can see in the megamanual it should be .75mm to 1.5mm. Maybe a 2mm gap is too much?

-

miniman82

- Posts: 3944

- Joined: Sun Apr 27, 2008 3:36 pm

Re: EDIS rpm issue, rpm reads high

Gap is really insignificant, as long as the sensor picks up the teeth you're good. The install I did on my Corvair has nearly an 1/8" gap because I eyeballed the mounting holes for the sensor, it still works fine. The unshielded wires on the other hand, that could be the source of your problem. Both the PIP and SAW wires MUST be shielded, and the shield MUST be grounded to a solid chassis ground. I took the cheap way out and wrapped it with tin foil, but they sell proper twin conductor shielded wire online if you want to do it the right way.

I'm willing to bet you're having noise issues- what's happening is the EDIS module is functioning correctly, so you're getting solid spark. But the spark noise from the coil firing is likely what's getting into your PIP line to the ECU, providing false triggers and confusing it into thinking there are more events than there really are. The manuals cover this in detail.

I'm willing to bet you're having noise issues- what's happening is the EDIS module is functioning correctly, so you're getting solid spark. But the spark noise from the coil firing is likely what's getting into your PIP line to the ECU, providing false triggers and confusing it into thinking there are more events than there really are. The manuals cover this in detail.

-

Clonebug

- Posts: 4719

- Joined: Thu Feb 15, 2007 9:28 pm

Re: EDIS rpm issue, rpm reads high

I ran a Twisted pair of wires for my pip/saw and they were not shielded.

They ran in my harness and I never had a bit of trouble with my signal.

I did have an issue with my tach running half speed and it turned out my ecu was set for an eight cylinder engine instead of a 4 cylinder. After changing that it worked great.

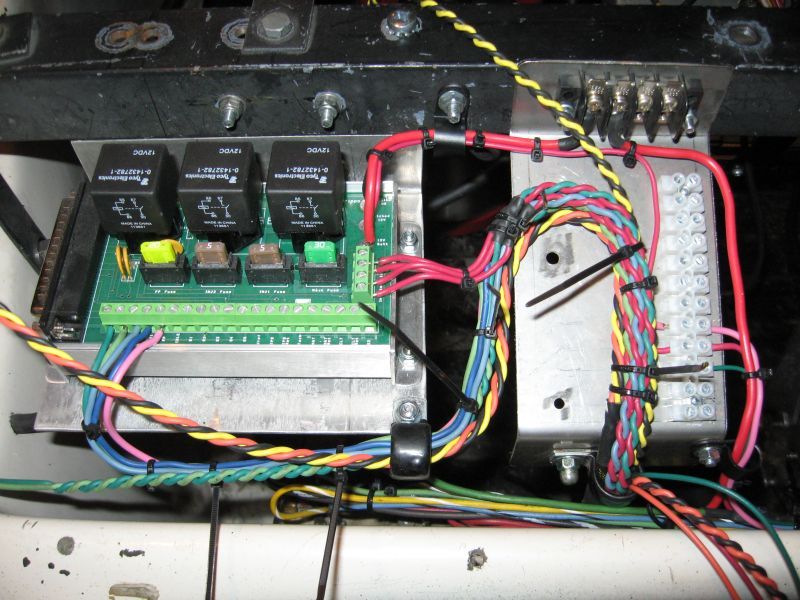

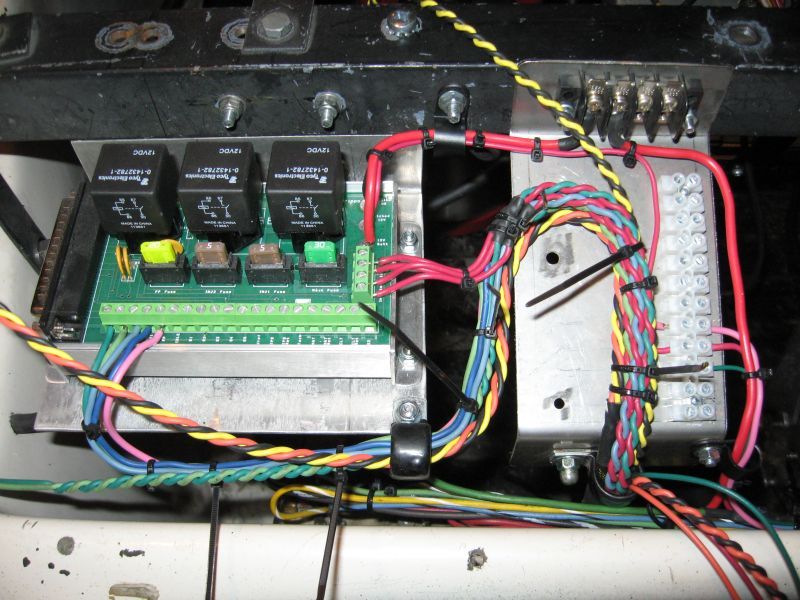

The dark green/Light green twisted pair are my pip/saw wires and you can see they run right in the middle of my harness.

They ran in my harness and I never had a bit of trouble with my signal.

I did have an issue with my tach running half speed and it turned out my ecu was set for an eight cylinder engine instead of a 4 cylinder. After changing that it worked great.

The dark green/Light green twisted pair are my pip/saw wires and you can see they run right in the middle of my harness.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: EDIS rpm issue, rpm reads high

whats the theory behind twisting the wires?

- fastback

- Posts: 1670

- Joined: Wed Sep 12, 2001 12:01 am

Re: EDIS rpm issue, rpm reads high

i had some similiar issues on my tach with edis when the engine did not fire on all 4 cylinders.

(hydraulic lifters bleed out after long storage,)

made some big random peak readings.

(hydraulic lifters bleed out after long storage,)

made some big random peak readings.

-

miniman82

- Posts: 3944

- Joined: Sun Apr 27, 2008 3:36 pm

Re: EDIS rpm issue, rpm reads high

wiki wrote:In balanced pair operation, the two wires carry equal and opposite signals and the destination detects the difference between the two. This is known as differential mode transmission. Noise sources introduce signals into the wires by coupling of electric or magnetic fields and tend to couple to both wires equally. The noise thus produces a common-mode signal which is canceled at the receiver when the difference signal is taken.

Thus it only works if the same signal is present in opposite polarities, cancelling out any noise introduced through outside sources. Since the PIP and SAW wires carry a different signal, this is an improper way to do things. The proper way is to shield both wires, and ground the shield.

-

jhoefer

- Posts: 195

- Joined: Wed Oct 05, 2011 2:30 pm

Re: EDIS rpm issue, rpm reads high

When you have two wires, outside EM interference will affect both wires, ostensibly generating an equal voltage change (via the induced current) in both wires, called a common-mode signal. Because the voltage generated by the interference is the same in both wires, and the receiver only cares about the difference in voltage between the wires, no problems occur. In actuality, the wire closer to the source of interference will couple more strongly to it, creating an imbalance, which will prevent the receiver from being able to fully reject the interference signal. By twisting the wires together, each wire is equally close to any interference source along its length, keeping the interfering signal "common-mode" and filtered out.andy198712 wrote:whats the theory behind twisting the wires?

In cables that contain multiple wire pairs, you want each pair to have a different number of twists per inch to prevent cross-talk between pairs. If the pairs all had the same twist/inch, the distance between the wires in different pairs would not change, allowing interference between them.

An outer foil or braided shield around the wire bundle acts as a faraday cage preventing outside noise from reaching the wires to begin with, or letting internal noise out. One end must be grounded. Good when you have a lot of EMI around like from an engine's ignition system.

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: EDIS rpm issue, rpm reads high

Cheers guys, very informative

-

fugazi885

- Posts: 13

- Joined: Mon Dec 30, 2013 2:35 pm

Re: EDIS rpm issue, rpm reads high

Thanks for the replies. I field stripped a length of coaxial cable and used both the foil and braided wire to shield the pip and saw wires, I tried connecting at pin 7 on the EDIS module and then to ground but either way I still have issues. Or perhaps it may have cured part of the issue? I'll try to explain... Now when I start the car it seems to run fine as long as the rpm stays abpve about 1300, when the rpm drops much lower it intermittently shows 0 rpm in tunerstudio and when this occurs the fuel pump relay will cycle and the engine fumbles and falls on it's face. If I feather the throttle I can keep it running and as long as you keep the idle high it seems to run smoothly. I tried adjusting the vr sensor a bit closer to the trigger wheel but made no difference, also tried swapping the EDIS module just because I had a spare but still no change. Double checked connections at the sensor and they look good, they are crimped and soldered weather pack connectors. It is my understanding that the vr sensor operates by generating an AC voltage as the trigger wheel passes it, is it possible that at low engine speed the AC voltage is too low for the module to pick it up? Could this be as simple as a faulty sensor? I am running the hidden sensor kit from the dub shop, does anyone know what sensor is supplied with that setup or what the resistance value should be? Mine measures about 870 ohms but fluctuates some when you wiggle the cable, maybe 10 ohms. I would think the resistance should stay rock solid, maybe there is a poor connection in the sensor itself?

-

fugazi885

- Posts: 13

- Joined: Mon Dec 30, 2013 2:35 pm

Re: EDIS rpm issue, rpm reads high

Stupid question, I just realized I have non resistor spark plugs. Could this be why I'm seeing wierd tach input? Or possibly plug gap? I know bad plugs or incorrect gap will obviously affect engine performance but I read on another forum someone with similar issues changed plugs and all was well. If so, what is the relation between plug resistance and what megasquirt is seeing for rpm input?

-

Clonebug

- Posts: 4719

- Joined: Thu Feb 15, 2007 9:28 pm

Re: EDIS rpm issue, rpm reads high

Plugs are cheap.......try them.

I set my gap at .028 with resistor plugs....I never had issues.

EDIS doesn't use wide gaps so stock at .024-.028 is just fine.

I set my gap at .028 with resistor plugs....I never had issues.

EDIS doesn't use wide gaps so stock at .024-.028 is just fine.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.

-

miniman82

- Posts: 3944

- Joined: Sun Apr 27, 2008 3:36 pm

Re: EDIS rpm issue, rpm reads high

You must use resistor plugs with EDIS, they are part of it's noise suppression function. Whatever you have in there now, find one with an R in the part number.

-

fugazi885

- Posts: 13

- Joined: Mon Dec 30, 2013 2:35 pm

Re: EDIS rpm issue, rpm reads high

Installed resistor plugs today, I have read conflicting information on the plug gap though so I may have to experiment with that a bit. Some say small gap, somewhere I read it should be upwards of .055. I set mine at .045 to try and split the difference and see what happens. Still has the same issue, low speed loss of rpm signal. I ohmed out all the plugs and wires, one thing that stands out to me is I have noise suppression spark plug wires. Resistance on each wire is about 12k ohms.... Maybe I have too much resistance? Are most people just running copper core wires with resistor plugs?