Welding a German fuel injection plenum?

-

roobar678

- Posts: 8

- Joined: Fri Sep 10, 2010 12:44 pm

Welding a German fuel injection plenum?

I am wondering if the German plenum can be welded on without any sort of exotic procedures. Is it aluminum or some magnesium alloy? The reason I ask is with the larger size of tubing going into the CB end castings, why doesn't anyone weld in larger pipe on the plenum? Wouldn't this give more flow/volume needed for a larger engine?

-

Clonebug

- Posts: 4719

- Joined: Thu Feb 15, 2007 9:28 pm

Re: Welding a German fuel injection plenum?

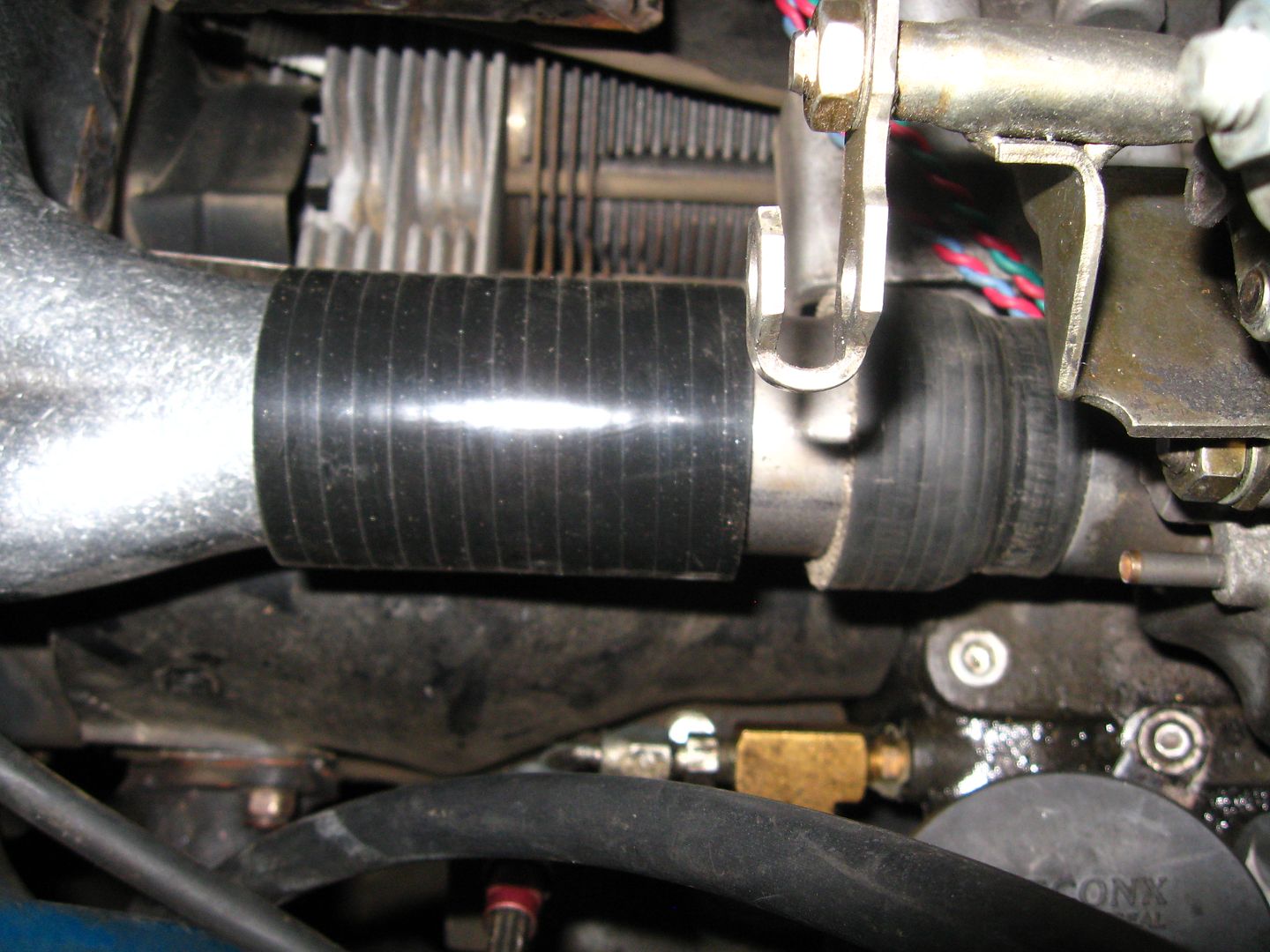

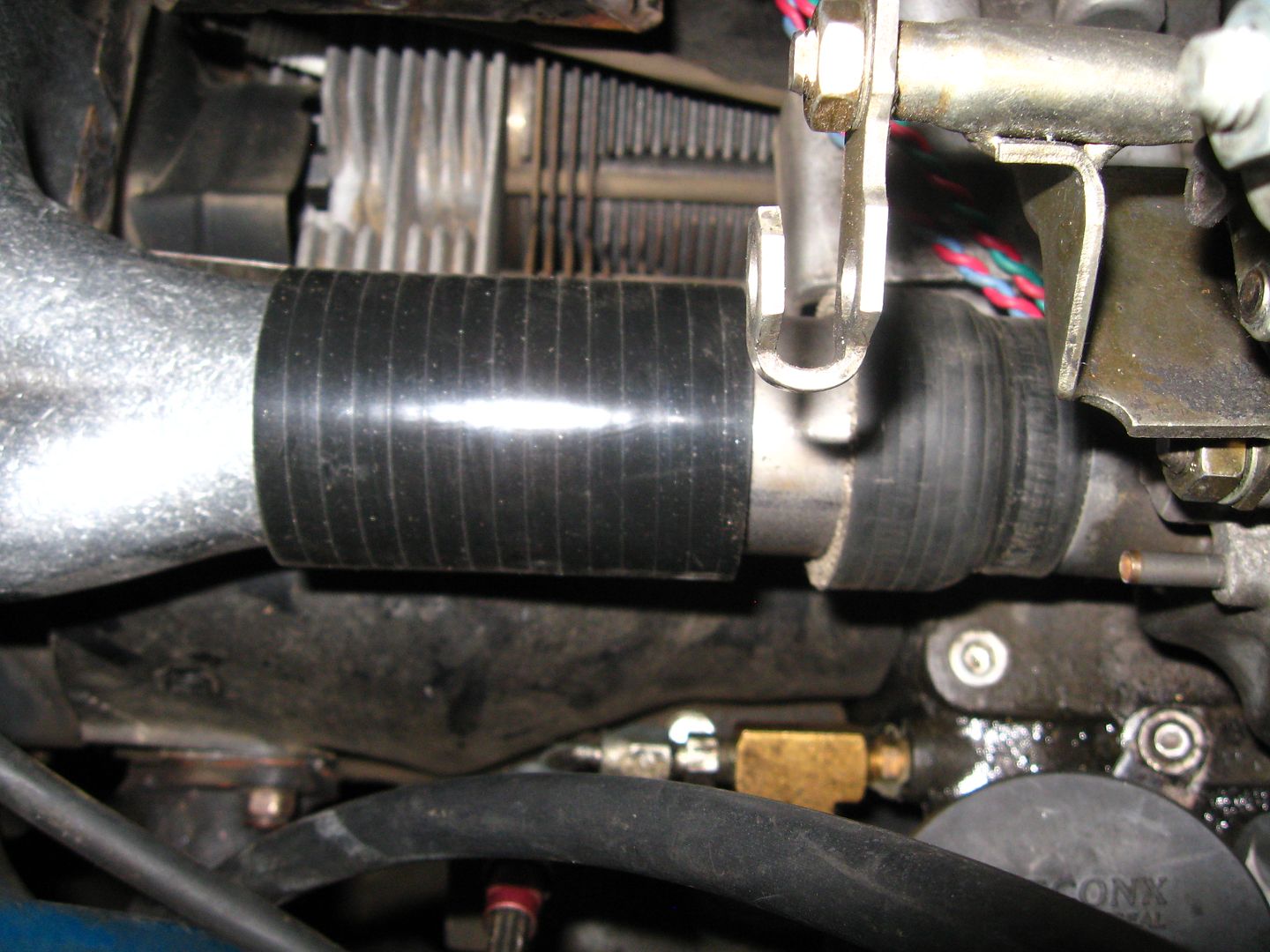

The outlet on the German plenum is 1 3/8th inch and the coupler size of the CB FI intakes are 1 5/8ths inch.

I just used the stock size coupler by the Plenum and then put a 3 inch piece of 1 5/8ths tubing between the two with a straight 1 5/8ths coupler on the intake side.

It increased the runner size a little bit but not much. There is not enough meat on the plenum to increase the outlet size by any measurable amount by drilling a larger hole but the short one inch long section of 1 3/8ths inch won't make much difference the way I see it.

Here is a pic of the larger size.

I just used the stock size coupler by the Plenum and then put a 3 inch piece of 1 5/8ths tubing between the two with a straight 1 5/8ths coupler on the intake side.

It increased the runner size a little bit but not much. There is not enough meat on the plenum to increase the outlet size by any measurable amount by drilling a larger hole but the short one inch long section of 1 3/8ths inch won't make much difference the way I see it.

Here is a pic of the larger size.

Stripped66 wrote:The point wasn't to argue air temps with the current world record holder, but to dispel the claim that the K03 is wrapped up at 150 HP. It's not.

-

Steve Arndt

- Posts: 7404

- Joined: Sat Mar 10, 2001 12:01 am

Re: Welding a German fuel injection plenum?

The plenum is sized for a 1585cc engine. Making the tubes bigger will simply over-vacuum the plenum volume that IS there.

Yes you can weld it. It should weld up just as pretty as any 35 year old oil soaked casting

Steve

Yes you can weld it. It should weld up just as pretty as any 35 year old oil soaked casting

Steve

Steve

My Baja Build

My Baja Build

-

roobar678

- Posts: 8

- Joined: Fri Sep 10, 2010 12:44 pm

Re: Welding a German fuel injection plenum?

Wow, thanks for the quick responses!

So assuming the new engine size is 2110 and the original is 1585. Would that mean the volume of the intake needs to be 33% larger or is the relationship not linear? (2110/1585=1.33) After looking at some random pictures of one disassembled, it does not look too difficult to make an new side that has the throttle body on it to increase the volume. This would also allow the flexibility to run any random throttle body. That being said, the runners are siamesed and I would think reversion would be an issue. That pretty makes this an academic discussion unless I am missing something.

So assuming the new engine size is 2110 and the original is 1585. Would that mean the volume of the intake needs to be 33% larger or is the relationship not linear? (2110/1585=1.33) After looking at some random pictures of one disassembled, it does not look too difficult to make an new side that has the throttle body on it to increase the volume. This would also allow the flexibility to run any random throttle body. That being said, the runners are siamesed and I would think reversion would be an issue. That pretty makes this an academic discussion unless I am missing something.