Which system?

If you're still deciding over what system to use, let's cover a few basics about some of the systems including cost, availability, ease of setup, and tuneability. The Bosch systems are mentioned first for swapping to an air-cooled engine and geared toward the user who isn't as concerned about programming for optimum horsepower--i.e. these systems are more 'set it and forget it.' A list of the car models, years, and types of systems are covered in the books 'Bosch Fuel Injection and Management' by Charles O. Probst, and 'How to Tune and Modify Bosch Fuel Injection' is also a great place to start.

CIS-There were millions of cars produced with CIS(mostly European), many of which are still running today. There are a few Bosch FI books on the market which cover all the models which used CIS. It is a very simple system to adapt and maintain. If you do have problems with it, a CIS fuel pressure gauge(about $80) will track down what the problem is. There are essentially three CIS systems.

CIS basic - this is a pressure based only system, no computer controls any of the components(common on cars from the early 70s to early 80s). The only 'electronics' are a relay which kicks the fuel pump on when it gets a signal from the ignition when it fires. As described above, individual fuel lines to each injector are routed to a central fuel distributor which has a piston in the middle of it. When the throttle body opens, an arm attached to the piston raises the piston allows more fuel to spray into each cylinder. The injector is constantly spraying, varying only the rate it sprays at, constant injection system(CIS). A warm up regulator is attached to the engine block which leans the mixture out from startup as the engine warms up. This is the easiest system to set up and maybe a good transition for a hardcore carb. guy to get used to. The only adjustments are a mixture screw on the airbox and idle speed on the throttle body. This is however the most limiting as far as tuneability. Since CIS works based on airflow, it adapts to any engine you put it on, especially the basic system(as long as the cam is not too heavy at idle). The mixture you set at idle works across the rev. range, just like a carb. In order to 'see' what's happening at the top end, you can use the same trick a lot of the drag racers use now which is a lean-rich meter hooked to an oxygen sensor. This still doesn't affect the operation of the CIS system, it just lets you know what is happening up top.

http://www.sdsefi.com/mmm.htm or

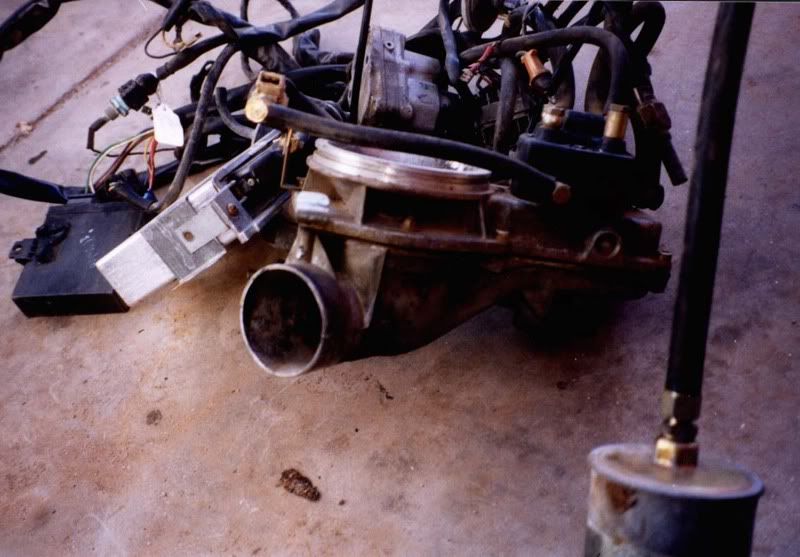

http://www.haltech.com/wideband_lambda.htm A CIS basic setup from a junkyard car can cost next to nothing(a list of all the stuff you'll need will come later), keeping in mind completely gummed up components may or may not free up with a little carb cleaner(i.e. it's better to pull stuff from a running car, or recently run). All replacement components(fuel distributor, injectors, seals, etc.) are still somewhat readily available on the market new and used, the most expensive component to replace is the fuel distributor $200-? and the injectors $40-80 each. To adapt to an air cooled engine, everything could be done in one long weekend but would be better done over a couple of weekends. The most challenging adaptations are mating the CIS fuel lines to the pump and return lines and tying this into the fuel tank, wiring a relay for the fuel pump, mating the CIS injectors into the intake manifolds, mounting the airbox, and fitting the cold start valve into the intake manifold.

CIS with lambda - This setup does have a computer which utilizes an oxygen sensor(lambda) to make tuning adjustments throughout the rev. range of the engine(early 80s to late 80s). This system is very similar to CIS basic though a little more integrated. These systems are also very adaptable to most any engine as the system is still based on air flow. The same two adjustments of mixture and idle are all that is needed. The systems are better than CIS basic as more hp and better fuel mileage can be achieved as the computer compensates and adjusts the return line pressure based upon input from the oxy sensor as the engine speeds up. Early versions of CIS used an iron(black) distributor with a modified fuel injector to control return pressure, later versions used an aluminum(silver) distributor with an integrated control valve known as CIS-E. CIS w/L is even more readily available than CIS basic new and used, well for obvious reasons as there were more of them on the road. Cost for replacement parts is similar to CIS basic with the addition of sensor costs. The ease of adapting to an air-cooled engine is similar to CIS basic with the addition of welding in a bung for the oxy sensor in the exhaust manifold, mounting the computer and harness internally, and mounting the various air and or water sensors for the computer.

CIS Motronic - This is mentioned only to cover our bases but not really recommended for adapting to your engine(late 80s to early 90s). These systems look similar to CIS w/L(CIS-E) externally, although the computer is much more integrated. They are not very adaptable to other types of engines as the internal maps built into the computer are specific to that type of engine the injection came off of(i.e. they do not like changes). Motronic is only mentioned if you happened to be swapping the whole engine from a donor car into yours, then they would work(i.e. putting a 16V 2.0L swap into a bug, etc.).

The Bosch pulsed injection systems:

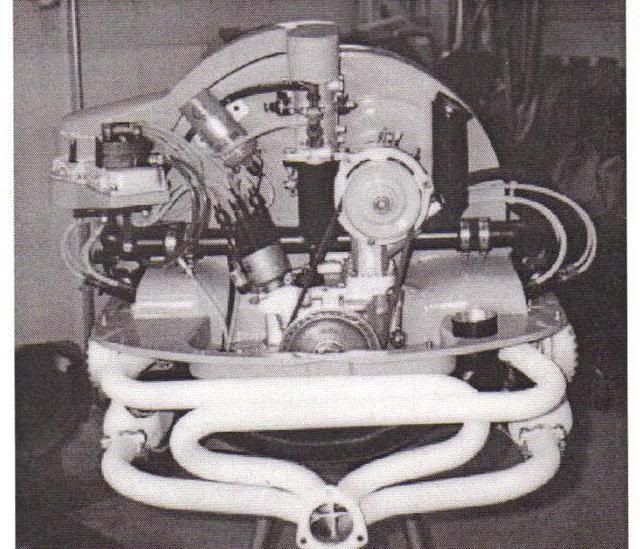

D-jet - This a very good, very reliable electronic system that came on late 60s to early 70s Type 3s, 4s, 914s, Mercedes, and some Cadillacs. Many of these systems still run today after over 40 years. They are easy to diagnose and many parts are still available. The drawback is they do not like heavy modifications. These systems are programmed to run off of manifold pressure(MAP), temperature, and throttle position. A couple of mild mods to your engine should be fine, but if your stock engine is modified too much D-jet will not be able to keep up. The obvious answer is if you have stock 1600 and bore it out to say a 1955cc, is to put injection from a bigger engine(like a Type 4). This will work, again as long as the cam is not too heavy at idle. It IS possible to modify, reprogram if you will, the D-jet 'brain' for a modded engine, but this is not something for someone not overly familiar with these systems or especially the new user. If you start tinkering with it and get stuck, oh well. These systems are cheap, a stock setup could be had for almost nothing off a parts car, the most expensive replacement is the three-outlet fuel pump which can cost up $100-300 rebuilt. Setting up a D-jet system, on a Type 1 for instance, would take a long weekend. As long as all parts are accounted for, the trickiest part would be installing larger fuel lines from the front to the back of the car.

L-jet - These are also very good, very reliable systems that started appearing on 914s, Type 4s, Buses and T1s in the mid-70s, then BMWs, etc. There is an air 'flap' in the airbox which opens according to the air flow into the engine when the throttle body opens. A resistor on an arm hooked to the air flap and input from the oxy sensor tells the computer how much fuel to inject into the engine. Since this system is based on air flow, it is very adaptable to engine mods, to a point. If you go too extreme you are limited by the system's throttle body, intake manifold, and air flap size along with the pulse duration and pulse frequency of the injectors. You can optimize the induction with bigger components and trick the computer to run a little richer overall, but you will still be limited with a very heavily modified engine. Again, if you have a smaller engine you bore out and adapt an injection system from a bigger engine, this will work. This, again, is not to say L-jet is not a good setup on a performance engine, I saw a L-jet on a draw through setup with a turbo, the owner only had to release some of the spring tension on the air flap to get it to work on his engine. Swapping airboxes with different computers is not recommended. Most all L-jet parts are still on the market with the exception of some of the airboxes which are getting harder to find, the airbox being the most expensive part to replace in the system. Fitting L-jet would also take a long weekend as long as all components are accounted for. The hardest part of the install is installing the fuel lines through the car, wiring the relays for the computer and fuel pump, mounting the airbox, and welding in a bung on the exhaust for the oxy sensor.

LH-jet - This setup is similar to L-jet but instead of an air flap a wire(mass air flow-MAF sensor) has current passed through it to heat it(on BMWs and Volvos in the mid to late 80s). As more or less air passes by the hot wire cooling it, the computer must compensate to keep the wire hot and is able to gauge with the oxy sensor how much fuel to inject in the engine. These systems have very little air restriction when compared to an L-jet system. As LH is also based on air flow(actually air density) these systems are adaptable to different types of engines. As Volvo engines tended to be sizeable(over 2L) compared to an air-cooled engine, an LH system would have no problem keeping up with a highly modified T1 or T4. Setup is similar to an L-jet setup, although cost of the system may be a little more than free from a junkyard as parts off of BMWs and Volvos tend to be pricey. The biggest cost in replacement parts is the fuel pump and MAF meter.

Digifant - This was an injection system developed by VW using Bosch components using an air flap meter similar to L-jet systems with the exception of the Corrado which used a MAP sensor(mid 80s to early 90s) with ignition and knock sensing built into the computer. The early systems which came on Vanagons controlled only fuel injection called Digifant I, this Digifant I setup also came on Corrados but used a MAP sensor and controlled the ignition system. Digifant II systems came on Golfs and Jettas and utilized an air flap with ignition control. The systems proved to be very reliable and somewhat adaptable to modifications.

Motronic - This is the most advanced pulsed system which controls fuel injection and ignition with the use of a hot wire sensor(early 90s-today). This system controls the firing of each individual injector vs. firing in pairs or batch firing. Motronic is similar to CIS motronic in that a few modifications are OK but too many and the system will register it as an error code based on the internal MAPs. The Motoronic can be reprogrammed, but is not something for the weekend mechanic.

Programmable systems:

These are DIY fuel injection systems that have become simple enough and affordable enough for the weekend mechanic over the last 10-15 years. These systems may or may not be more affordable than a system off a production car(junkyard) but the advantage is they are new(the central brain at least in most cases) and you can control precisely how much and where in the powerband your engine makes power.

Megasquirt - This is arguably the cheapest, most extensively used aftermarket FI systems around. You purchase the central controller or brain, but have to supply the other components for the system to work(injectors, harness, pump, sensors, manifolds, etc.). The system works on inputs from a MAP or MAF sensor along with temperature, throttle position(TPS), ignition, and you have the option of using an oxygen sensor. The newer version 3.0+ (MS Extra) you can also utilize a hotwire sensor or MAP sensor or both, along with knock sensing ignition control a variety of ignition configurations (distributor, EDIS, MSD, COP, or CNP). You can control up to 16 injectors with odd cylinder combinations(such as 3 or 5 cylinders), as well as boosted engines(up to 21psi). All programming is done from a computer, the software used to program is freeware downloadable from the MS website or Tunerstudio (recommended). You can control how long the pulse duration is, how many times the injector fires per second, where in the power band(rev range), along with start up(richer) sequences as well as the ignition with more advanced kits. The setup and support are extensive

http://www.megasquirt.info Costwise, the controller is only a little over $100 unassembled (if you don't mind soldering) and a little over $200 for a basic system assembled. All other components could be bought new(injectors, pump, wiring harness, etc.) but if you're on a budget you have the option of using the components from a junkyard car. Powerwise, the limiting factor will be manifold and throttle body size as performance of the engine is increased. BE ADVISED, even if you buy a fully-assembly kit or DIY kit, due to the nature of megasquirt usage you WILL be heavily involved in a lot of research and reading to find answers and instructions because this is one of the lower priced systems on the market.

Simple Digital Systems(SDS) - This is a very straightforward pre-assembled system for different cars (including VWs) which doesn't require a computer to program, but offers the same extensive tuning of an aftermarket system. These systems utilize a MAP sensor and TPS along with a temp. sensor(oxy sensor optional), are able to control ignition up to 9750 rpm with the option of crank-trigger, work on boosted engines, and you have the option of knock sensing, fan control, supercharger clutch, etc. Their complete systems are supplied with the brain, LCD dash module for programming, injector and sensor a pre-assembled harnesse for your car and plug in cables, dash module for extra lean rich control, and they sell any other the necessary components if need be(sensors, relays, even injector bungs). Their connections are designed to work with Bosch injectors. Their website is very extensive and straightforward,

http://www.sdsefi.com A typical system can cost just under $1000 to $1700, but this system is more complete compared to an Megasquirt system(i.e. you get what you pay for and this will save you vast amounts of time and potentially headaches). Their website is a good read, funny at times too. A lot of the info. and setup they give is geared toward using the factory Bosch FI stuff(e.g. if you had an L-jet equipped bus or something, this system would be pretty much plug and play after mounting the TPS on the TB).

Electromotive - This was one of the first aftermarket systems to come out on the market which controls fuel injection and ignition. Using GM style sensors, the system uses a MAP sensor and TPS along with temp. controls to control 1-8 cylinders(except 5) and 12 cylinders with the option of dual plug ignition control. The ignition pickup is by crank trigger, a rev. limiter is built into the controls and the system is able to work on boosted engines. All programming is done from a computer and there are some extra functions such as extra injector control, fan and alternator control(for drag racing), shift light, torque converter, etc. These systems are complete but tend to be pretty pricey.

http://www.directignition.com

Weber Redline - This is another MAP sensor based system utilizing engine temp., TPS, air temp., and oxy. sensor inputs and crank-trigger wasted spark or COP applications are possible. The system is fully programmable for different performance applications from a computer. These systems are all-inclusive and plug-and-play, as in a kit is designed specifically for T1 engines, more or less like the version of carbs Weber would sell for years in different setups(DCOE, IDA, etc.) but with injectors in them instead of floats and jets. These kits are very pricey at over $3000 for a complete system, but again they come with everything to fuel inject your T1 engine including the manifolds. The limiting factor seems to be limited to dual throat throttle bodies(no single), and limited only to the T1 engine(although with the correct base intake manifolds and linkages it should be possible to inject a T4 as well).

http://www.redlineweber.com

Haltech - This was one of the first programmable aftermarket systems on the market, an Australian made FI system with a range of different ECUs controlling 1-6, 8, 10 or 12 cylinders and ignition control up to 16K RPM using MAP, temp., oxygen, and TPS sensor inputs on N/A or boosted engines. The ECU is capable of sequential injector firing, direct or wasted spark ignition firing, boost control, data logging of the engine, and an optional digital dash display/control which is really neat. The ignition pickup is either through a pointless distributor or crank trigger sensor. These systems are complete with harness, throttle bodies, injectors, etc. available through Gene Berg

http://www.geneberg.com

034 Motorsports - A fully programmable aftermarket system which utilizes a MAF sensor, can run up to 1-8 cylinders sequential (depending upon kit) or 1-12 cylinders batch fired, distributor or crank-trigger ignition with wasted spark by coilpack or coil-on plug at a good overall cost. They offers universal kits and all sensors for adaptations. Very cutting-edge and they have a very good reputation.

http://www.034motorsport.com/034efi-eng ... -c-22.html

CB Performance - Another longtime provider of fuel injection systems and components that has been in the VW aftermarket. Supplies complete kits with dash tuning modules or individual components for converting a VW engine to FI (manifolds, fuel rails, etc.). Kit works on MAP based sensor and utilizes GM/Ford sensors and works with most ignition systems including a CB crank trigger system.

http://www.cbperformance.com

Big Stuff3 - Supplies universal (for VWs in this case) kits, sensors, and components. Sequential fuel controller up to 16 cylinders individual, utilizes oxygen sensor, and capable of COP ignition.

http://www.bigstuff3.com

**Of note on aftermarket programmable systems, many of them require you to plug in with a laptop or other type of computer. The technology to communicate between ECUs and laptop can be very troublesome. You can spend several hundred or even thousand dollars on a system then come to find out you cannot even communicate with the ECU because your computer does not have the right connection. Most modern computers use a USB port now for all communications. Most aftermarket ECUs do NOT use a USB because of the cost associated with maintaining and supporting the USB drivers. Many aftermarket systems use either a 9 pin serial port or RJ11 connection (phone jack type--uses four wires instead of two for a dial-up connection). You will have to crossover using a RS232 9pin to USB converter (and then a serial to RJ11 adapter if an RJ11 connection is required) to get the correct connection established. Finding the correct communications port and baud speed/settings all can be very frustrating and time consuming. Just be aware of this ahead of time. Look at your computer, does it have a 9 pin serial port (two rows of 5 and 4 pin holes)? If you don't have this, the video card (15 pin) or phone jack (has only two wires) will not work. The computer will only communicate externally through the USB port.

USB issues collection of threads.**