Page 1 of 2

LED light problem

Posted: Sun Mar 12, 2017 4:30 pm

by dustrat

Decided to change bulbs on my 73 12volt Ghia to LED. Single contact bulbs for flashers and reversing no problem but when I changed double contact stop and tail bulbs only stop lights work. Put old bulbs back in and every thing OK.The contact segments on LED bulbs are the same and as are offset pin fitting I've checked LED bulbs and both stop and tail segments working. Any ideas what might be problem.

Robert

Re: LED light problem

Posted: Sun Mar 12, 2017 4:48 pm

by Piledriver

I'm running Sylvania Zevos on my 73 T3 (same taillight assy as late Ghia)

no issues: Bright as hell, and work with the reflectors.

Your turn signal flasher may need upgraded to an electronic version, the old school versions relied on lamp current to "switch".

The LEDs draw a lot less current, and may flash very slowly if at all with an original flasher

Re: LED light problem

Posted: Mon Mar 13, 2017 6:04 am

by sideshow

Running lamps are not effected by the flasher. I would suspect a collapsed push pin in the housing if it lights on the bench OK.

Re: LED light problem

Posted: Mon Mar 13, 2017 10:03 am

by Marc

Haven't experienced this, but here's a thought. Are you certain that the grounds are good? Specifically, the ground contact between the shell of the lamp and the bulbholder (since the signals work the bulbholder itself must have a good ground). Incandescent double-filament lamps will kinda-sorta work with a bad ground (although with interraction between bright & dim filaments) because current can find an alternate path to ground through the other filament and via the common wiring to the grounds of other bulbholders. Since LEDs only pass current in one direction, that "backfeeding" isn't possible.

Re: LED light problem

Posted: Mon Mar 13, 2017 1:21 pm

by dustrat

Thanks again for advice. First of all I have not changed the flasher unit over but will get a EP35 LED Flasher unit tomorrow. After reading more on the subject it seems that is the problem with flashers.

Im also going to try something else with tail lights.

The brass tabs on lamp that make contact with bulbs are OK and are making contact with LED bulbs. Current must be coming through as normal bulbs work. Will put another post tomorrow and let you know outcome.

Robert

Re: LED light problem

Posted: Tue Mar 14, 2017 1:40 am

by Piledriver

One of the bulbs I bought was bad first time out one of the chips was installed backwards, no current=no light.

Buying locally helps, esp if you swap them in the FLAPS parking lot.

Don't forget the dielectric grease and, clean those sockets, the pot metal sockets are far more of an issue than the brass bits.

Re: LED light problem

Posted: Tue Mar 14, 2017 11:57 am

by Marc

di•e•lec•tric (dīˌĭ-lĕkˈtrĭk)►

n.

A nonconductor of electricity, especially a substance with electrical conductivity of less than a millionth (10-6) of a siemens.

Dielectric grease is an INSULATOR, designed to stop the flow of electricity. Legitimate uses are to seal the rubber ends on sparkplug wires or to slather over an already-made-up connection to block moisture from getting to it and causing corrosion.

It should NEVER be used on surfaces that are supposed to be making electrical contact - for some reason in the automotive field its primary use seems to be misuse.

Re: LED light problem

Posted: Sun Mar 19, 2017 3:05 pm

by Piledriver

OK, you made me look it up...

I had previously posted a long response to that, but it seems to have been digested by the board upgrade.

I'll limit it to this,

it only covers "noncritical" appications like aircraft, spacecraft, and nuclear weapons.

The tragedy of Apollo 1 may not have happened if the connectors were properly filled with dielectric grease...

That was a lesson learned the absolute hardest way. (that and don't run electrical junk in pure oxygen)

The proprietary blend used below AFAICT is possibly fluorocarbon grease, although PAO oil is in there too, perhaps as an antioxidant. It may also be just a PAO oil in a teflon-powder based thickener.

(There is such a thing as fluorocarbon soap, so ...)

I assure you its absolutely a dielectric compound, none better..

https://www.google.com/search?q=mil-l-8 ... 8&oe=utf-8

and

http://www.asetsdefense.org/documents/p ... 20Navy.pdf

For most of our more pedestrian uses, silicone grease works absolutely fine, as long as it is a well designed connection with a wiping and spring action. Spade connectors count as long as they are tight.

Ideal use is in a sealed connector, as it wont dry out.

Don't use it on Molex connectors.... In fact, don't use Molex connectors on anything, they suck.

The air and water-tight seal is the goal, Molex connectors have ~no wiping action, and little spring.

Also, don't use it on relays, as at least theoretically silicone oils can outgas and insulate the contacts with silicon dioxide (AKA quartz), and small signal relays usually don't have enough wiping action on the contacts to self clean.

Power relays like you would use in a car usually do, so I don't sweat it.

I don't mount relays where they can get wet as a rule.

Re: LED light problem

Posted: Wed Mar 29, 2017 7:17 am

by Dale M.

IF you have good solid mechanical contacts in electrical connections dielectric grease is a non issue as insulator, it's beneficial uses are it keep oxygen and moisture out of connection to prevent corrosion... I use it exclusively on almost every automotive wiring project (crimp on connectors) and bulb socket on all my vehicles and in home (yes screw in light bulbs) and have yet to encounter a problem caused by dielectric grease...

As for turnsignal problem, its a flasher issue.... Normal old style flashers are thermal operated and large amount of amperage flowing through them to light incandescent bulb cause flasher to operate... With LEDS the amperage is minimal and will not cause thermal flasher to operate, WITH LEDS as turn signals you need flasher (electronic not thermal) designed to work with LEDS or to add load resistor...

http://c1.staticflickr.com/3/2502/38859 ... dbb6_o.jpg

http://c1.staticflickr.com/8/7432/87223 ... 5cb973.jpg

Sorry it does not display image as forum software/editor does not want to accept URL as a valid image...

Dale

Re: LED light problem

Posted: Wed Mar 29, 2017 1:41 pm

by Marc

dustrat wrote: ↑Sun Mar 12, 2017 4:30 pm

Decided to change bulbs on my 73 12volt Ghia to LED. Single contact bulbs for flashers and reversing no problem...

Robert

And yet almost everyone seems convinced that you had a flasher problem.

I guess when the only tool you have is a hammer, every problem looks like a nail

Re: LED light problem

Posted: Wed Mar 29, 2017 4:16 pm

by Dale M.

Marc wrote: ↑Wed Mar 29, 2017 1:41 pm

dustrat wrote: ↑Sun Mar 12, 2017 4:30 pm

Decided to change bulbs on my 73 12volt Ghia to LED. Single contact bulbs for flashers and reversing no problem...

Robert

And yet almost everyone seems convinced that you had a flasher problem.

I guess when the only tool you have is a hammer, every problem looks like a nail

Aaaah... I read it wrong like everyone else.... Its the tail lamp function that did not work NOT a turn signal problem...

All I can suggest is you put a little more contact pressure on tab that contacts bulb... Maybe polish both bulb and contact....

Dale

Re: LED light problem

Posted: Thu Mar 30, 2017 2:45 am

by Piledriver

The socket/ground locating notches tend to corrode, where the little side nubs lock in//connect...

Its usually only pot metal (zinc alloy) even if chromed, it will corrode over time even if kept dry just from humidity

once you scrape them clean put a dab of silicone dielectric grease on everything to preclude further corrosion. (unless you can score the magic stuff the military uses these days, haven't looked if they sell it on ebay. Yet...)

Re: LED light problem

Posted: Thu Mar 30, 2017 1:57 pm

by Marc

Bulbholders that are stamped sheetmetal are pretty easy to tweak in place with a small screwdriver to get them to grip the bulb better; a simple trick for the cast ones is to use a paper matchstick as a shim - they're laminated paper so you can peel them apart to make just the right thickness.

Re: LED light problem

Posted: Fri Jun 09, 2017 5:09 pm

by Piledriver

For a simple graphic mansplaining connector lubrication, see

https://www.nyelubricants.com/stuff/con ... _final.pdf

I admit, after decades of training and practice of "absolutely clean and dry" for electrical contacts, learning about using electrical connector lubricant feels kinda like discovering electrical contacts are are a

million times more reliable if first covered in

creamy peanut butter...

The ~WORST thing for reliable connections esp in a high vibration/humidity environment is clean and dry.

Pissing on it would be worse, but not by much.

Peanut butter might actually work better.

ALWAYS using connector cleaner/lubricant/protectant is the new "correct" way.

This stuff is only $15/spray can, highly rated, and can be used for general corrosion control as well as electronics/electrical connectors.

https://pilotshq.com/zip-chem-cor-ban-5 ... 14769.html

Re: LED light problem

Posted: Sun Jun 11, 2017 6:47 am

by Dale M.

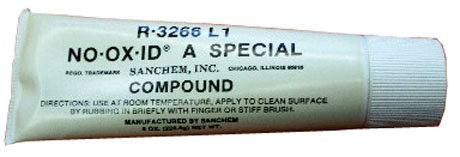

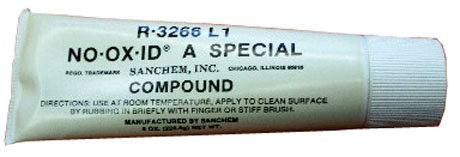

When in work world (telecommunications) for 38 years we used NO-OX-ID (grease) on all mechanical or crimped power cable connection from #8 to 750,000 CM cable, and all connections to batteries and inter-cell connectors... IT was a requirement...

Still use it on batteries on personal vehicles, and if battery terminal are prepped correctly (clean and polished) there is absolutely no corrosion at batteries for life of battery... First thing I do when "new" vehicle comes home, is clean and prep battery cables/connectors (replace cables if necessary on used vehicles) .. Absolutely no problems with battery connections there after..

These replacement connectors absolutely will not be used on any of my vehicles as they are first source of any battery troubles which they are supposed to repair..

Dale