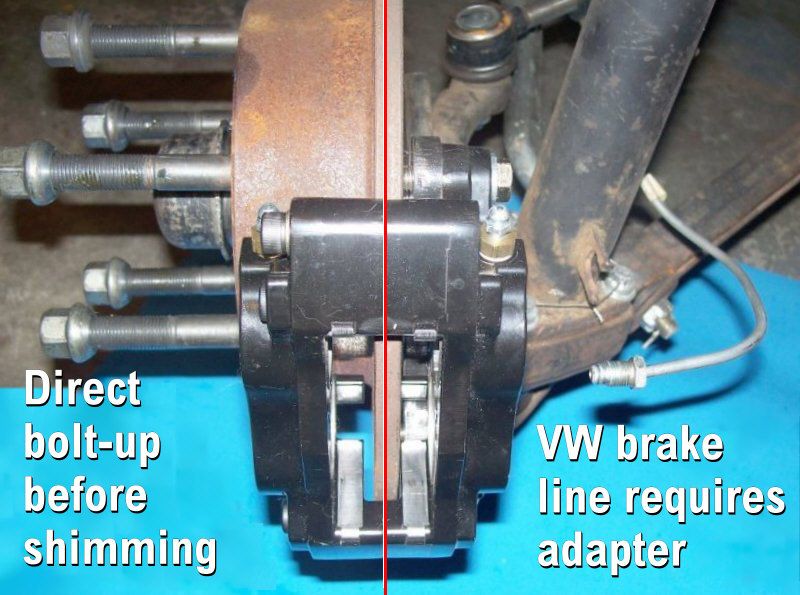

Wilwood Dynalite (about $125 ea) caliper being fitted to our LeMons SuperBug. That's silver anti-seize on the rotors and studs. We plumbed a brake bias valve into the front circuit to adjust for modulation, and were very happy with the result.

Porsche was last to the street sports car disk brake crowd, only installing disks to the 356C in 1964. Triumph, for instance, had front disks for the TR3 in 1956. Jaguar first raced on disks in 1951, winning LeMons with an XK120C roadster, and changed to four wheel disk in 1956-57 for the XK140 series.

Porsche believed its drum brakes were just fine for street and light track use (read club racing), but began experimenting in racing with disks in 1959 on a 356A in the Nürburgring, and took a class win. Disk brakes became the norm for most Porsche racers, but the street 356 had a problem. Designing a disk brake system for what the VW people today call "wide five" wheels was problematic.

The factory did design its own wide-five system but it was too heavy and bulky -- similar to but worse than the wide-five disk brake kits today. So, Porsche adopted the ATE (Alfred Teves GmbH) caliper with solid rotors to all four wheels on the 356C, which required a new bolt pattern, new wheels, and hubcaps. The one-year issue 356C then became the brake system test mule for the upcoming 1964-65 911.

The ATE caliper as first used by Porsche for the 356C, the 912, and the early 911's had dual 48mm front pistons and 35mm rear pistons.

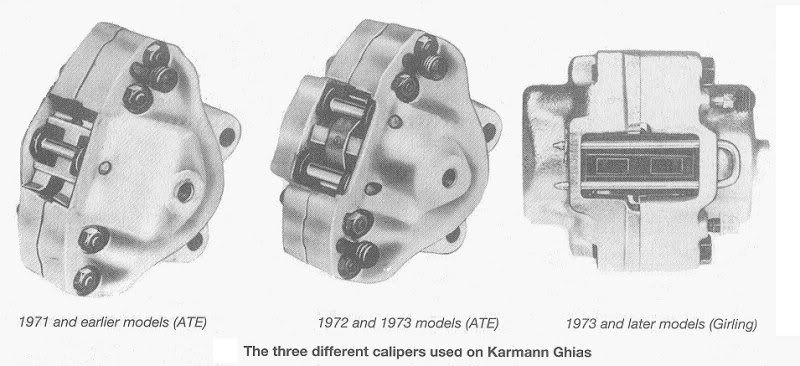

Finally, in 1967, VW decided to upgrade the Karmann Ghia to front wheel disks, the original single-pin ATE caliper design being updated to a larger two-pin ATE caliper and slightly larger pad in late 1971, officially for the 1972 model year.

The U-pin Girling that replaced the twin-pin ATE soon disappeared into obscurity, and the twin-pin ATE caliper became the standard in VW disk brake kits. The Girling caliper had to be removed from the car to change pads, so good riddance

The business arrangements are complex, but TRW and VARGA (of Brazil) copied the ATE design, and today, it appears the VARGA copy is being eclipsed by a generic Chinese copy.

There are small physical differences between the ATE-VARGA-Chinese versions. For instance, the VARGA rebuild kit is not guaranteed to be the same as the ATE kit. I have personally compared the more recent VARGA kits to original ATE, and seen differences, and talked to others who saw none for the first VARGA kits made years ago.

And the bleeders can be different between all of them. The Chinese bleeders are the largest of all.

When fitted with high-performance pads, the ATE design caliper is very effective, so much that on stock pads and bias-ply tires, back in 1972, a 70-0 panic brake test in Road & Track a disk/drum Ghia stopped quicker than a 911.

That implies that the Ghia had better brakes, right? No. just better at 70 and under because the Ghia was lighter.

The 911's brakes were better over 70mph. Specifically, the 911 could slow from 100 to 70 with force and control. Or from 130 mph to 100.

To get brakes equal to that for your VW takes two things. The first is the power to get to 100 mph and exceed it. The second is brakes big enough, with sensitive modulation, to stop in a straight line, lap after lap.

Brakes that are too big, with poor modulation, in any street car only cause lockups at low speeds. Common street driving speeds. That means bigger brakes don't fix sliding, they can cause sliding.

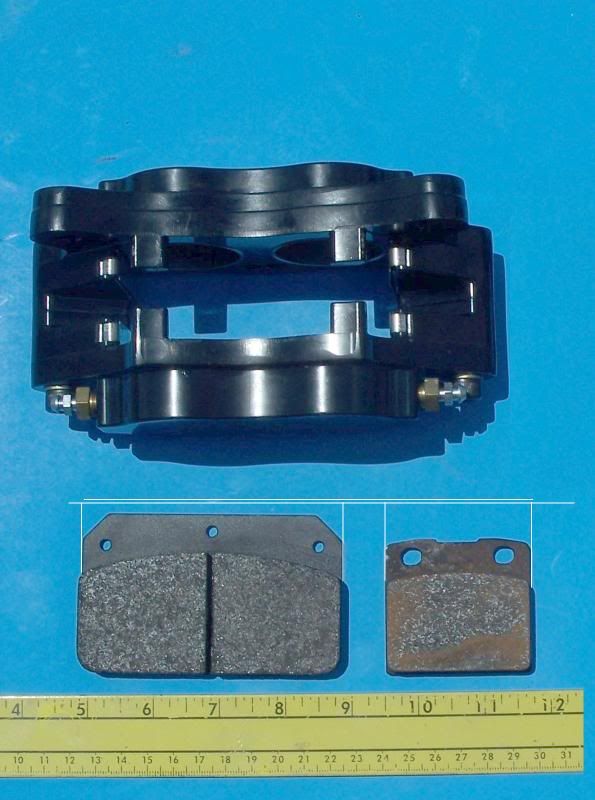

The Wilwood Dynalite caliper, made of forged aluminum and packing four 37mm pistons, was actually designed for average weight (2500 to 3500 lbs) street sedans with 300 HP. Lots of short round track V8's use them.

We VW people are lucky the Wilwood Dynalite caliper, working with a 19mm to 20.6mm VW master cylinder and the stock VW brake pedal leverage ratio, can be modulated well enough to be raced and even driven on the street.

At one time, 924 or 944 brake upgrades for the VW sedan or Ghia were the thing to do. Now, the Wilwood upgrade is easier and the payoff as satisfying.

The Wilwood pad has about twice the surface area as the ATE. This is better for pad life, cooling, and stopping friction.

Our custom-made 5.25-inch space caliper brackets come from http://www.vdubengineering.com They produce quality hardware.

Vital tech note for those who are planning to use one of the black-billet EMPI brake bias valves. On ours, the IN and OUT ports on the body were reversed. And they are engraved, not just marked with paper stickers. When we installed the lines off the master cylinder the marked way, the IN coming from the master cylinder and the OUT going to the brakes, the brakes would drag and lock. We actually found this same warning on the Internet from an EMPI bias-valve user. Hooking the lines up "backwards" fixed it.

FJC