ABOVE: 261 braking so hard the headlight grille broke loose of its clips and flew off the car. Note that the rear tires are flat and straight, no jacking is occuring.

THE CAMBER COMPENSATOR REVISITED

We field-tested our camber compensator modification at a local SCCA autocross today, to see how it would perform under abrupt turns, accelleration, and braking, all dynamics guaranteed to upset swing axles. For all you with the IRS rear end, please go read something else. This is for us desperate swing axle racers.

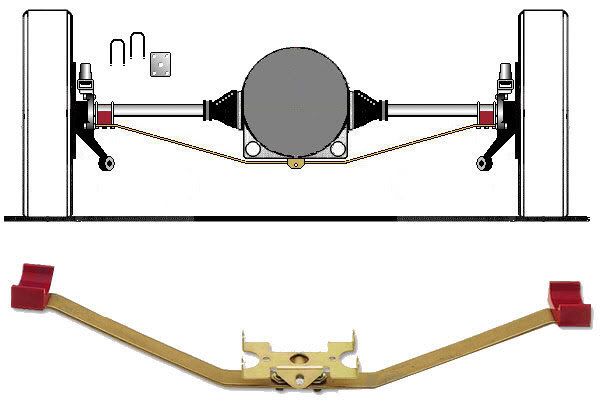

Here is the modification, applied to a Sway-A-Way spring.

The modification is simple, the ends of the spring are U-bolted to the rear axle, with enough slack to not create a preload, and to allow the axle to slide in and out of the U-bolts as it moves up and down.

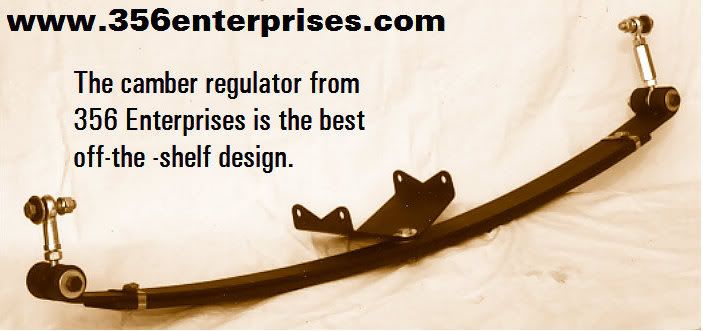

Porsche introduced what it called the rear axle "compensating spring" with the Super 90 in 1960. Here is what the factory wrote about it:

REAR AXLE COMPENSATING SPRING ON SUPER 90 AND CARRERA

In order to further improve the road holding qualities of our sports car, the Porsche Engineering Department has equipped the rear axle with a compensating spring.

This compensating spring is a single blade steel spring, tapered on both ends, which is supported at the center by the transmission housing, it's ends being connected to the radius arms by means of tie rods and rubber [illegible] It acts as a kind of counter-stabilizer, i.e., inversely to the stabilizer mounted on the front axle, and designed in such a manner that in conjunction with new torsion bars designed to match, with an equal wheel load the rear suspension properties remain unchanged, whereas with an unequal load the suspension will be softer.

How does the rear axle with compensating spring affect the road holding qualities of the Porsche car as compared to the rear axle without compensating spring?

Curves can be taken at greater speed since the tendency to oversteer is reduced and also the rear axles tendency to break away is smaller. As a consequence less steering correction is necessary. Less oversteering signifies that when cornering the front axle now absorbers a greater part of the resultant forces. And finally, skidding of the rear wheels caused by too fast cornering is slower and more even. The car gives a warning and the driver has plenty of time for correction.

When driving on straight uneven roads there is a continuous unilateral thrust movement of the rear wheels which with the rear axle with compensating spring is smaller than the rear axle without compensating spring. The car is thus less subject to jolts especially when driving at high speeds which [illegible] greater stability.

The rear axle with compensating spring is not only advantageous in competition driving, but it also means more comfort in every day driving and more safety in emergencies.

The compensating spring may be optionally installed in all other cars in which transmission with tunnel housing is fitted.

The factory reduced the Super 90 and Carrera rear torsion bars by 1mm (24mm to 23mm) to soften the rear suspension for more roll, making the front axle and front sway bar take more of the load.

So, if the factory wanted a softer rear supension, and our mod with the Sway-A-Way spring would obviously add some roll stiffness by joining the spring to the axles, there was some element of risk involved. We might be creating a scary oversteering or understeering car, especially in violent autocross style manuvers.

But it didn't work out that way. The modification increased overall stability, and predictable understeer. On the fast sweepers, the 1965 Ghia exhibited steady-state understeer, and on zig-zag slaloms, the rear end could be thrown out easily but recovered just as easily.

We think the success of the modification is due to the moderate rate of the Sway-A-Way spring. It is on the softer rather than harder side. But, harder compensator spring rates have been used on Porsche 356's, notably in this privately developed device:

The end links bolt to the rear axle spring plate assembly, and allow preload.

ABOVE: Swing axles -- uncontrolled -- allow jacking and "tuck-under" of the rear tires.

Another swing axle taming trick is the simple but effective "flop stops."

The flop stop is a spacer installed at the base of the spring plate that prevents the spring plate from travelling all the way down, adding a slight amount of negative camber and resisting jacking. We use them on 261 as well. Every little bit helps.

Now, to test a double camber compensator spring like the 356 version shown above ...

FJC

PS: We've never autocrossed 261, and in fact have been away from autocrosses since 2007! And 261 is not a "slalom car" it is a cross country road racer. Be that as it may, the big figure-8 course we ran today (14May11) was set up for Corvettes.

The fastest cars ran 32-34 seconds. The slow cars ran 40+ seconds. Barret drove 261 to a best time of 38 seconds, 261's mild enduro 1600 engine pitted against cars that had three to four times our power.

And for that third of the field we beat overall, ponder tonight a swing axle did it to you.