Race Modifying the Type 1 Axle Beam

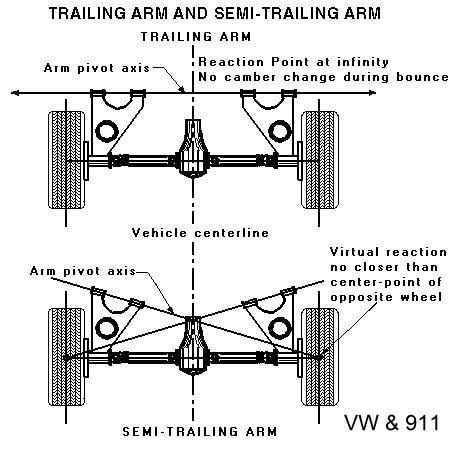

The VW Type 1 axle beam started life as the front suspension for Dr. Porsche's "P-Wagen" Auto Union Grand Prix racer. It allowed for an inboard suspension, and rigidly mounted to the chassis so that it leaned with the body, a breakaway of front tire adhesion to provide progressive understeer -- the more lean, the more understeer.

Front Roll Stiffness and Handling

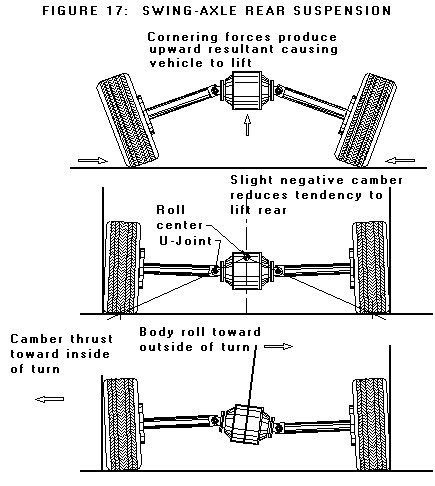

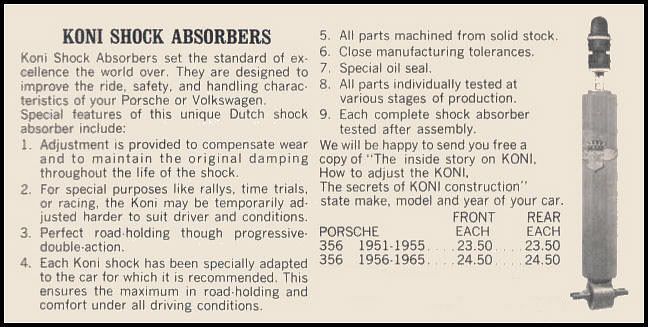

The VW and Porsche chassis (swing axle and IRS) depend on stiff front ends and soft rear ends to handle properly. The very design of the Type 1 front axle beam was originally considered by Porsche engineers to not need a front sway bar, and did not get one as a handling tuning aid until 1954! The Ghia got one next in 1955.

The addition of a front sway bar allowed Porsche and VW to slightly soften the front torsion leafs for a better ride, but maintain the right amount of front roll stiffness.

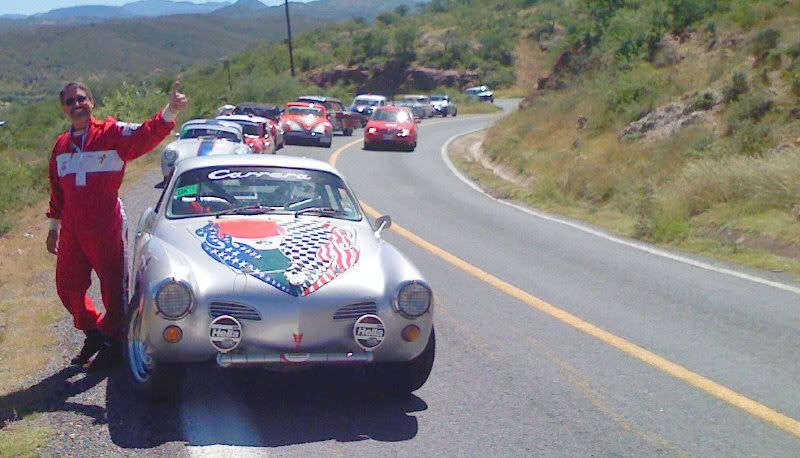

The Porsche 356C axle beam

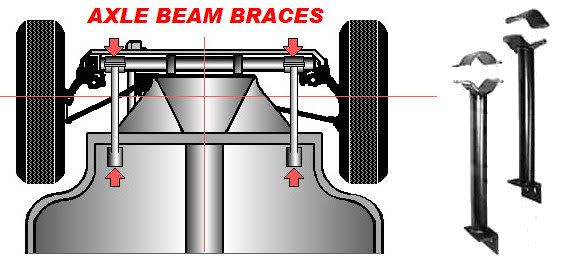

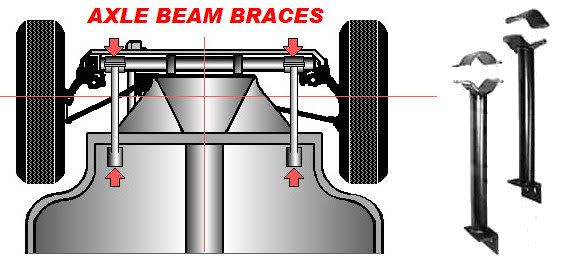

Porsche used the same design of front axle beam as VW for its 356 sports car, but braced its ends to stop deflection caused by cornering loads. Deflection means bending with a return to the original position, and bending affects handling.

Bracing Your Axle Beam

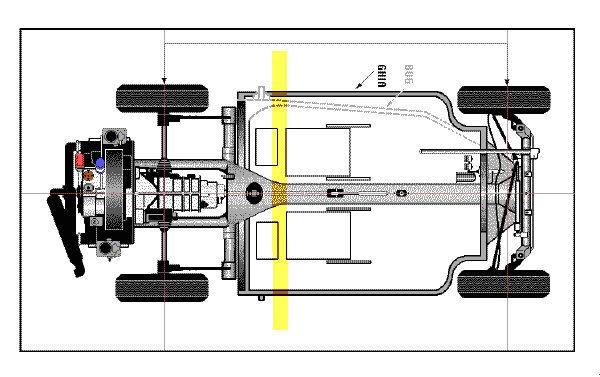

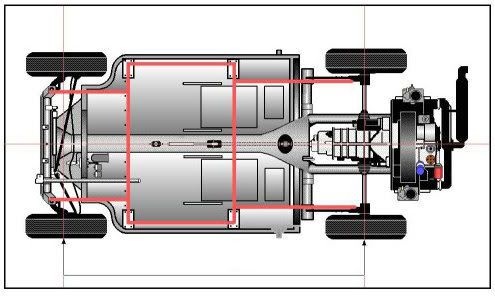

You can -- and should -- brace your front axle with inexpensive supports. This drawing shows one type, and here is a link to an example of what is commonly available.

http://www2.cip1.com/PhotoGallery.asp?P ... D413%2D151

Be advised these mounts sometimes interfere with the grease nipples on the front axle, being just close enough to block a grease gun from fitting snugly. And, they definitely interfere with tow bars.

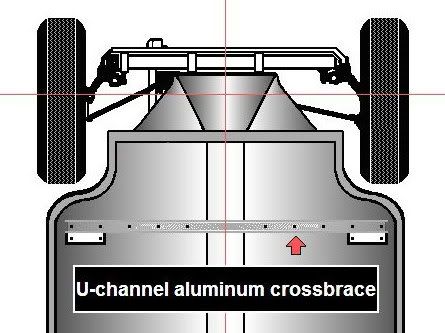

Boxing Your Trailing Arms

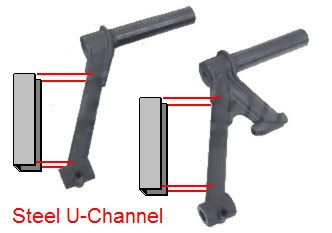

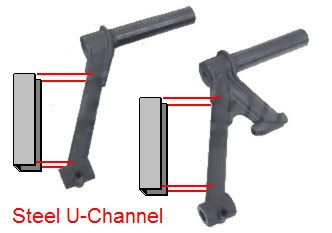

Front trailing arms deflect as well. The 356 racers also brace their trailing arms by welding steel U-channel over them. They began this after seeing how the arms would deform when loaded by high G-forces when racing tires were used.

Install Neoprene Trailing Arm Bushings

Just as previously described, the deep, full-length neoprene sleeve bushings better support the trailing arm inside the beam.

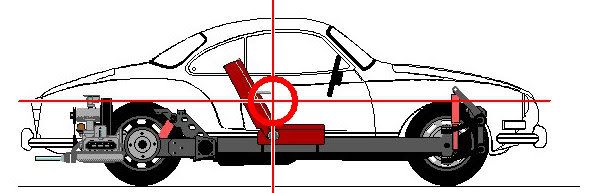

Lowering the Front End

If you lower your Ghia, you don't want to adversely affect suspension geometry ... so for handling, until you get very advanced, you do not lower the front without lowering the rear, preferably both by exactly the same amount.

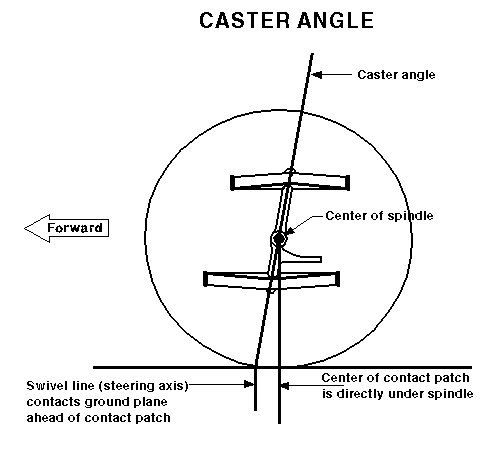

First, as mentioned before for performance application, lower no more than two inches. Dropped spindles are excellent for this. They retain the steering box/tie rod alignment and do not create "bump-steer" problems. Bump steer is exactly what it sounds like ... a bump causes the car to self-steer. When you lower the front of almost any car, the tie rods are no longer going to be the right length for full suspension movement, and when, with wheel travel, the tie rods becomes too long or too short, it's going to push out or pull in a front wheel for you.

At racing speed, this is dangerous.

The second best way to lower the front end is with an adjustable front axle beam. The brand name Puma is one of the best known for this. The axles have a movable center mount for both top and bottom torsion bar leaf stacks, and the mounts can be rotated and locked in such a way as to raise or lower the suspension ride height by changing the starting point of the torsion bar resistance.

With an adjustable axle beam, you jack up and brace the front end of the car, loosen the nuts holding the setscrews on both top and bottom axle beam center mounts, remove the lock plates, and the torsion leaf stacks are free to rotate inside the axle beam. A little experimentation with a jack to move the front end up and down a few times as you reset the lock plates, and you can find your desired ride height.

There is a misunderstanding about adjustable axle beams, however. Many purchasers presume "adjustable" means at least from stock height to low and back up to stock again if desired. But, some axles only provide a starting point that's at least two inches lower than stock, and going back to stock ride height is no longer possible. Ask your supplier before you buy.

Front Axle Lowering Tricks

There are some tricks you can do with adjustable axle beams that make them more useful than just a way to lower the car.

For one, you can loosen the center mounts so the torsion leaf stacks have no effect at all, and install coilover front shocks so the front ride height and spring rate can be set much more precisely.

On a dune buggy, you can release one torsion leaf stack (either one) and leave the other engaged, reducing your springing by half and reducing the increased ride height caused by loss of the weight of the car body.

If you feel experimental, you can free up one torsion leaf stack and run adjustable coil spring shocks (not technically coilovers) and set them for spring rate, to affect front roll stiffness.

Front Sway Bars

Front Sway Bars

As we mentioned before, Porsche did not start using a front bar until late in 1954, followed shortly by the Ghia. The Bug got one a year later.

The big difference was in the thickness of the Porsche and VW bars, and how they were mounted. Porsche used a 16mm front bar secured at its ends for a very strong mount. VW clamped a very light bar to the lower front trailing arms. This simple clamping reduced the effectiveness of the bar, and allowed for it to sometimes work loose.

You can fabricate mounts to hold your front bar in place. This mounting arrangement also dramatically increases the efficiency of the bar, making it function like a much stiffer one.

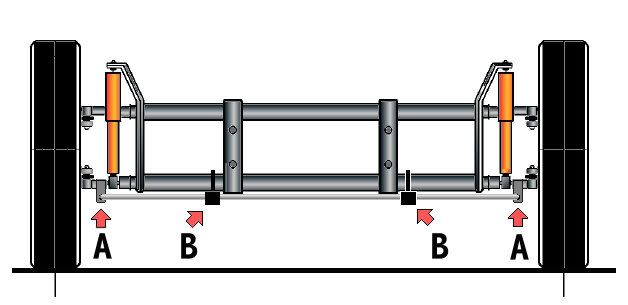

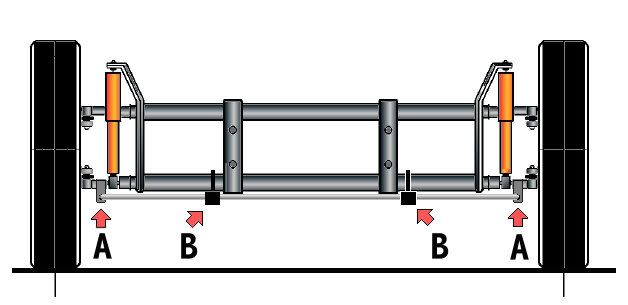

"A" represents the stock mount. "B" shows improvised additional mounts.

The standard nonadjustable front bar upgrade for the Porsche and VW is 19mm. This size seems to work for most people for both street and track use.

These clamps are far better than stock, and install easier to boot.

Adjustable Bars

Adjustable Bars

Whiteline makes a good adjustable front bar. Adjustment here means changing the bar's stiffness. In this photo, the bar end link to the lower control arm is set to the softest setting.

The reason for an adjustable bar of any sort is to allow handling changes for different tracks. A stiffer bar means more understeer. As a rule, the faster you go, the less oversteer you want.

Understeer =

leave the road forwards trying to turn.

Oversteer =

leave the road backwards trying to turn.

If adjustable bars are part of your tuning tactics, you can have an adjustable front bar and nonadjustable rear, or vice versa. The ultimate would be adjustable front and rear bars. On 53, we use a nonadjustable 19mm front bar, and a nonadjustable 19mm rear bar or a 22mm adjustable rear bar ... or no rear bar at all.

An enhancement to swaybar tuning is adjustable end links. The Whiteline front bar shown earlier comes with a fixed length end link. An adjustable end link (especially one with heim joints where applicable) allows you to fine tune preload. With zero preload, the bar at rest exerts no resistance on either side of the suspension. This is the normal setting.

With preload, all slack in response is eliminated, and suspension responses are quicker.

Adjustable end links also allow compensation for bent parts, running on banked tracks, or for weight redistribution.

Next -- the rear suspension.