Last week our freezer we keep in the garage had it’s thermostat go out again. Since it was a ’89 unit and since there were some sales going on we purchased a new one. My wife, being a person of great perspicacity in some areas keeps track of things and acts accordingly. She was out last night checking the new freezer out… again when she noticed some tape on the rear corner of the freezer. Being a person of action she pulled the tape off and found what she thought was a dent and she came in irked and complained about the dent to me.

I finally gave up and went out to check. Looking at it then checking the other side I found the same thing. What it was is an error in manufacturing and design. I mention stress risers a lot and the so called dents are indication of there being one at each of the top corners of the bent “tin” and this was a good example of just that.

(for more information of stress risers do a search on either stress risers or stress concentration (https://en.wikipedia.org/wiki/Stress_concentration). You can also do some research on the de Havilland Comet Comet and the discoveries made after the three crashes and the putting an airframe in a big water tank then pressurizing it through many cycles then finding out that square windows were the problem. This was in the late 40 or early 50s. (http://lessonslearned.faa.gov/ll_main.c ... LLTypeID=2)

These pictures are something I posted several years ago on how to relieve stress fractures and/or stress deforming. Basically it is drilling a hole at the apex of the corner cutaway where the flanges meet.

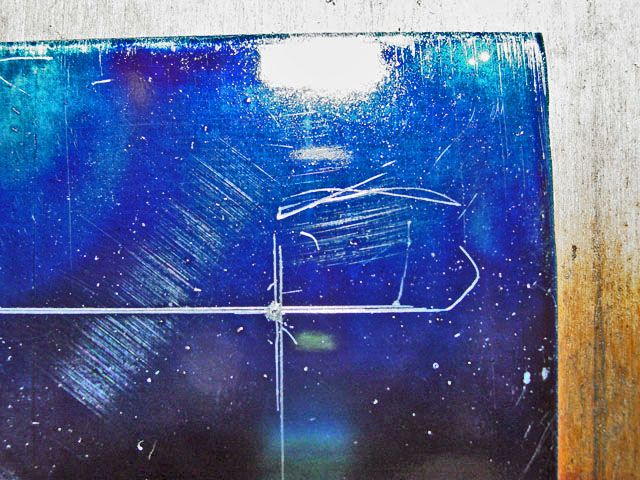

This is the plate I was making flanges on on all four sides. I sprayed Bluing on all the sides to use for scribing my bend. I didn’t go to the detail of marking OMLs or IMLs as I didn’t think that in this case it wasn’t that important as my bends were not to be 90° but 45°. The flanges were not to be structural as much as keeping liquids in the tray if I ever added liquid cooling.

Here you can see the corners (I double checked parallelism and found a slight error hence the double lines) then drilled a hole the diameter of which was double the thickness of the material. It could have been bigger but this was the minimum. After the bending then I welded the legs together as well as the relief hole.

This shows the pattern and the cut lines to remove the overlap now added for the bend.

If you don’t do the relief the corner of the bend will want to rise and you can see where the bend is pinched to the max on the underside of the material and stretched to the max on the outside of the bend. The radius of the bend as it gets to the corners will hump rather than lay flat and that is what caused the dent/dimple my wife thought that had happened.

As I have said before, when you bend metal the inside of the bend compresses and the outside of the metal stretches. You can only go so tight before either cracks start happening. If you bend something and the outside of the bend takes on a gray color those are stress cracks starting to form. In the inside of thin material the bend can start to fold over on itself kind of like a Pittsburg lock. Flat stock and tube both can act like this.

Square stock is a bit different as the inside of the bend will form a bowl. If you look at tube furniture you can see this if the bend isn’t done correctly. When I was doing some heat bending of square tube if I pulled the sand out too quickly the bowl would form. I had some square tube deform (the bowl) after sitting OK for over a year.

For what it is worth… before I forget all this stuff.

Lee