Compression Ratio explained by Scott The Viking

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

-

Bugfuel

- Posts: 3011

- Joined: Fri Apr 20, 2001 1:01 am

David58bug wrote:I just can't see how dynamic compression ratios don't exist. Am I missing something here?

Uhh, they do, but to be able to figure it out, you would need quite a bit of math and/or measuring. It would be nice to know, but since it is so troublesome to obtain, nobody bothers, and it is better to just not use the term, because it most likely will be misleading. It is not a de facto standard when talking about engine compression, like the static CR is. Too high of a risk of misunderstandings.

I should have worded it better. They exist, but aren't commonly used, therefore useless for 99% of people.

It is information that's hard to get, and hard to utilize.

Someone may be able to come up with a chart that shows approximate correlation between cylinder peak pressure and Dynamic CR. Such a list would however be too inaccurate to be of any use, there's too many variables in generating cylinder pressure (leaks)

My opinions only of course. Do some research to see if it is being used somewhere and how.

Jan

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

I searched for days and found no chart that showed dynamic compression ratios. So I say it doesn't exist. In the real world Static compression is measured and reveled in charts and studies all over the world.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

- Plastermaster

- Posts: 2762

- Joined: Sun Sep 30, 2001 12:01 am

The chart would have to be so component specific that it is more useful to do just as you stated, draw up a specific calculation. This is where it gets real interesting and covers all the variables you refered to in your first post. Things like port velocity. The intake charge is sort of force fed into the chamber due to the inertia of that charge. That is why the valves are left open a tad longer than the bottom of the pistons travel. We have 3 pages going here we might as well get into these subtleties.scott the viking wrote:I can, and do so on a weekly basis calculate dynamic compression ratios (it's what I do for a living). You could not make a chart...well...you could, but it would not tell you anything relevant.

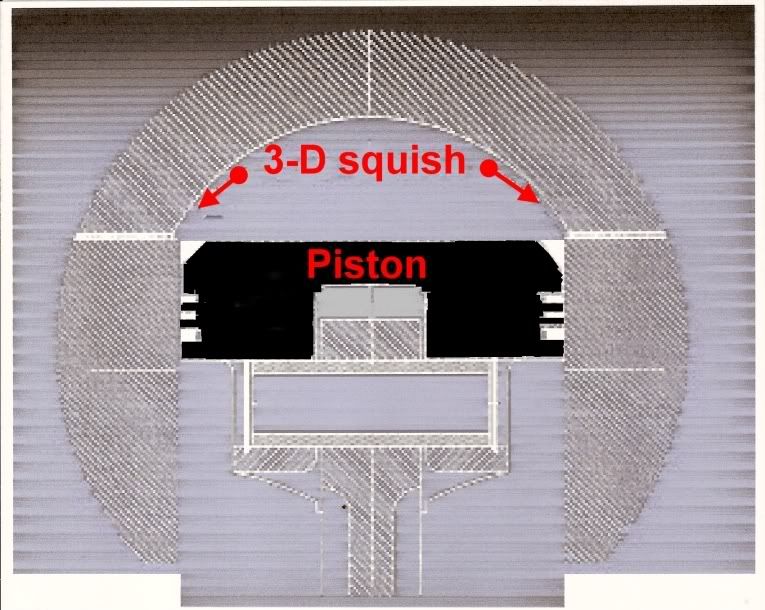

To say DCR does not exist is overlooking the obvious, but remember, it is really just a concept that you come to through number crunching. It is a tool that is usually "good enough" for engine design. One area it falls short on is air density. As someone stated earlier, cylinder pressure is more to the point. The same engine with a given DCR will have less peak pressure operating in a lower air density than higher. It may sound like a miniscule effect, but in real world driving it does matter. After DCR is figured, you have a more or less idea of whether the engine will work within its capabilities to not ping and to cool itself. I would guess it is better to start with your choice of cam, heads, pistons, (to squish or not to squish) and then shoot for a measurement of DCR or pressure, rather than to pick a CR and then design an engine around that. That way you can determine what are the limits of your cooling system, the heads and cylinders being cooled, and all the rest. There is a big difference between cast iron jugs topped with an after market 3 fin head Than a set of nickies with a T4 head.

Also I have heard that about 60% of cooling is internal, but I am sure with the wrong configuration it could be less, but that 60% shows the importance of making correct choices of components.

Ron

- Plastermaster

- Posts: 2762

- Joined: Sun Sep 30, 2001 12:01 am

[quote="David58bug"]Dynamic Compression Ratio

The DCR does not change at any time during the operation of the engine

However, the actual pressure does. the faster the piston travels the less time there is for the pressure to bleed off. As RPM increases peak pressure builds. That is why long duration cams result in higher rpm efficiency and may run poorly at low rpm.

Ron

The DCR does not change at any time during the operation of the engine

However, the actual pressure does. the faster the piston travels the less time there is for the pressure to bleed off. As RPM increases peak pressure builds. That is why long duration cams result in higher rpm efficiency and may run poorly at low rpm.

Ron

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

Atmosphere makes a BIG difference. Not a performance example by any means...but a long time ago I had this old Ford truck that would ping like mad when pulling a trailer up a hill at near sea level. But as I would go up to a few thousand feet...it would soon stop. Intake manifold can make a HUGE difference, as can carburetion. A good example of this would be when I build an engine that will be required to run a restrictor plate...cr can be bumped WAY up.

-

Bugfuel

- Posts: 3011

- Joined: Fri Apr 20, 2001 1:01 am

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

David posted the text from the KB-Silvolite site, here's what everyone probably really wants:

dynamic compression ratio calculator :

http://www.kb-silvolite.com/calc.php?action=comp

Also compensates for rod length.

Enjoy.

A stock T4 2.0 bus ~6.6:1

a 914 2.0 is 7.3:1

Over 8:1 DCR, plan on running premium, if lucky, unless you have very special combustion chambers, or are running E85 or propane etc.

Under ~6.5, a turbo had best be in your plans.

dynamic compression ratio calculator :

http://www.kb-silvolite.com/calc.php?action=comp

Also compensates for rod length.

Enjoy.

A stock T4 2.0 bus ~6.6:1

a 914 2.0 is 7.3:1

Over 8:1 DCR, plan on running premium, if lucky, unless you have very special combustion chambers, or are running E85 or propane etc.

Under ~6.5, a turbo had best be in your plans.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Bugfuel

- Posts: 3011

- Joined: Fri Apr 20, 2001 1:01 am

I'll say this one more time: the above quote was out of context, missing one critical piece of information: valve timing. You cannot say anything about CR or octane requirement without knowing the valve opening and closing events, in other words, know the CAM.Piledriver wrote:Over 8:1 DCR, plan on running premium, if lucky, unless you have very special combustion chambers, or are running E85 or propane etc.

Under ~6.5, a turbo had best be in your plans.

Then add what you know about the chambers and deck height etc.. they have a noticeable effect, but nothing near as dramatic as the cam profile.

9:1 would cook the engine if it had a stock cam, but if it had a race cam, the engine would not run properly because it had too LITTLE CR.

6.something :1 is too low for most applications, and yes it does sound like a good turbo CR for a mild cam. But you can also build a turbo engine with 9:1 CR, if the cam was wild enough. It would allow pressure to leak past open valves during the early stages of compression stroke.

CR is just the theoretical ratio for IF you had both valves closed all through the compression stroke, and no lossses anywhere.

an

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

Sorry, I thought the acronym would be clear..

DCR would be Dynamic Compression Ratio, and what I said was in context. as it includes valve timing.

I was trying to keep it straightforward, referring to pump gas, no restrictor plates etc.

The current motor I have going together has a ~10:1 static, and 7.3:1 dynamic compression ratio, and the cam is hardly wild, just a 119 on wide lobe centers.

DCR would be Dynamic Compression Ratio, and what I said was in context. as it includes valve timing.

I was trying to keep it straightforward, referring to pump gas, no restrictor plates etc.

The current motor I have going together has a ~10:1 static, and 7.3:1 dynamic compression ratio, and the cam is hardly wild, just a 119 on wide lobe centers.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

It was clear, and thank you for the calculator.Piledriver wrote:Sorry, I thought the acronym would be clear..

DCR would be Dynamic Compression Ratio, and what I said was in context. as it includes valve timing.

I was trying to keep it straightforward, referring to pump gas, no restrictor plates etc.

The current motor I have going together has a ~10:1 static, and 7.3:1 dynamic compression ratio, and the cam is hardly wild, just a 119 on wide lobe centers.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

I've been waiting for someone to raise that point.Plastermaster wrote:The DCR does not change at any time during the operation of the engine.

However, the actual pressure does. the faster the piston travels the less time there is for the pressure to bleed off. As RPM increases peak pressure builds. That is why long duration cams result in higher rpm efficiency and may run poorly at low rpm...

For a theoretical engine running at impractically low RPM, there'd be no need to play with valve timing events - you'd close the intake at exactly BDC, for example - and the static & dynamic compression ratios would be identical. But in the real world things are happening too fast for that and the object is to get the cylinder as full as possible before you start to compress. The ideal valve timing required to do that is affected by many factors - and it varies with RPM, hence the development of VTEC. http://en.wikipedia.org/wiki/VTEC

When considering C.R. (either static or dynamic) "everyone" gets that it's a number telling you how many times the cylinder volume is reduced when the piston goes up - what tends to be overlooked is that the peak cylinder pressure is dependent upon how efficiently the cylinder was filled to begin with.

- Piledriver

- Moderator

- Posts: 22520

- Joined: Sat Feb 16, 2002 12:01 am

I think Bugfuel and I are really saying the same thing, just having a communications breakdown.

In a nutshell, I feel that anyone building a motor needs to sanity check their setup vs that calculator (or do the math) as static compression ratio is only of use for bench racing.

When I was a kid, I slapped a Bugpack 4063 (296 advertised) into an otherwise mostly internally stock engine, and was happy, as it made all the right noises and was fun to drive due to the powerband.

Knowing what I know now, I was probably throwing away a LOT of gas, and missing out on ~30-40% of the power it COULD have been making.

with a ~300 degree cam, a "high" static CR is not just a good idea... It's really required so the dynamic CR is in the sane 7>7.5:1 range.

As a datapoint on head temps, the old Pile 1700, I tossed it's head gaskets and base gaskets on the jugs, raising the static CR from ~8:2 to ~8.6:1. If anything it runs much COOLER head temps, although I did have to optimize the total timing. (ended up retarding a couple of degrees)

Jake has also repeatedly noted cooler head temps when running proper CR.

A fellow in England is running ~9:1 static/stock cam in a 2.0 T4 in a splitee (>8:1 dynamic by the numbers I can come up with) and his max head temps are perfectly fine, but he did have a lame VDO TC gauge, reading ~50 degrees F high. (96x71)

In a nutshell, I feel that anyone building a motor needs to sanity check their setup vs that calculator (or do the math) as static compression ratio is only of use for bench racing.

When I was a kid, I slapped a Bugpack 4063 (296 advertised) into an otherwise mostly internally stock engine, and was happy, as it made all the right noises and was fun to drive due to the powerband.

Knowing what I know now, I was probably throwing away a LOT of gas, and missing out on ~30-40% of the power it COULD have been making.

with a ~300 degree cam, a "high" static CR is not just a good idea... It's really required so the dynamic CR is in the sane 7>7.5:1 range.

As a datapoint on head temps, the old Pile 1700, I tossed it's head gaskets and base gaskets on the jugs, raising the static CR from ~8:2 to ~8.6:1. If anything it runs much COOLER head temps, although I did have to optimize the total timing. (ended up retarding a couple of degrees)

Jake has also repeatedly noted cooler head temps when running proper CR.

A fellow in England is running ~9:1 static/stock cam in a 2.0 T4 in a splitee (>8:1 dynamic by the numbers I can come up with) and his max head temps are perfectly fine, but he did have a lame VDO TC gauge, reading ~50 degrees F high. (96x71)

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.