sorry for the long delay. I spent the last few days in the Land of Port in that strange land where aging pump jockeys are obliged to fuel your car.

Well, this is a very educational hijacked thread.

I am going to keep my steel wheels, mostly since they are paid for.

I am going to spend the money I saved on shocks.

I'm stoked this is coming across as valuable information. I agree that it would be better to invest the money on quality shocks first. I'm sure Chris will agree.

Seriously, though...dampers are to a suspension what speakers are to an audio system. You'll get the most results from the least expense. When properly tuned to weight, spring rate, and suspension design, a damper will transform a car in all the right ways. Just remember to go monotube with a valve design that has more than just bleeds. But that's material for another hijacked posting.

Actually, I have boxes of old press parts, hmmm.

Oh god. This thread can't handle any more hijacks...unless they have the prospect of a Chandler & Price Pilot for a low price at the end of the rainbow. My wife's a graphic designer and she wants one real bad-like.

Steel wheels are great in some applications and not so good in others. On sand they are a great weight penelty and the un-sprung weight is well noticed.

Absolutely...but they have penalties just the same. On your lightweight short-wheelbase car in the sand and trails your lightweight spun wheels are perfect. That's the ideal application. However, a few people have mentioned how easy they are to mangle on a heavy car in the dirt--definitely not the ideal app.

Forged wheels aside (which are regretfully and ironically underrepresented in this corner of the sport) the only other option is cast, which is usually the same weight as steel.

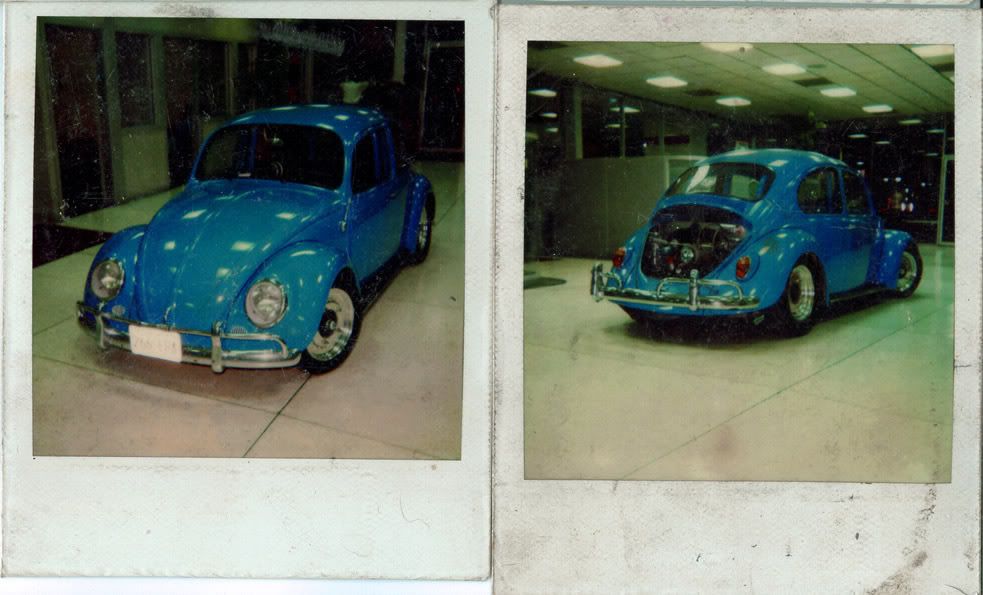

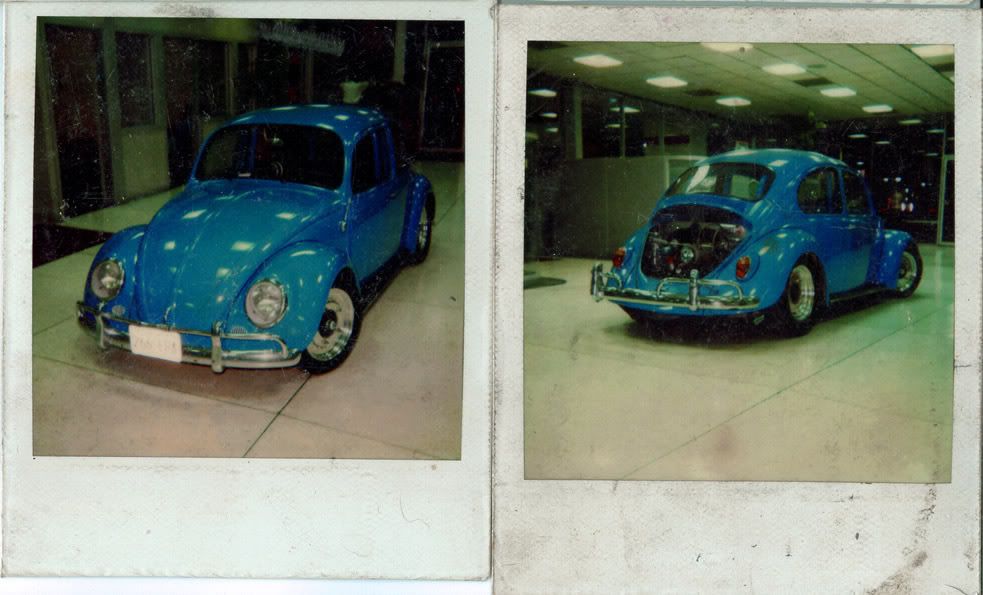

And yes, the weight difference can be staggering. Once upon a time when I was cool, I had a big-engine car with Centerlines. On a lark, I installed some stock steelies. It felt like I went from a 2110 to a 1776. The car felt like a pig and even rode worse--and on the street at that!

magnesium has some ridiculous manufacturing problems doesnt it? It needs to be forged as a powder if I am not mistaken, not as a solid slab.

That's a good question, and even though I'm not qualified to do so I'll take a stab at it. From what I've heard mag forges pretty easily. Actually, this chart at the following site lists all sorts of pre-formed shapes for magnesium materials that can be forged.

http://www.steelforge.com/forgings/forgingchart.htm

The powdered- or sintered-metal manufacturing process is a world of its own, and it can be done with just about any material/alloy (cast iron, even). I don't know tremendously much about it, but I know it can make fairly strong parts and the process is pretty efficient. In the late '80s or early '90s Toyota got real big into making powdered-metal connecting rods, and from what I know they were damn strong for the cost.

Casting mag can be tricky as anyone who lived within a dozen miles or so of the TIMET plant in Hooterville (Henderson) Nevada whenever it had a fire. The company processed titanium, which requires magnesium if I remember correctly. My friend's grandfather was an engineer there, and he hated that he had to work around hot mag.