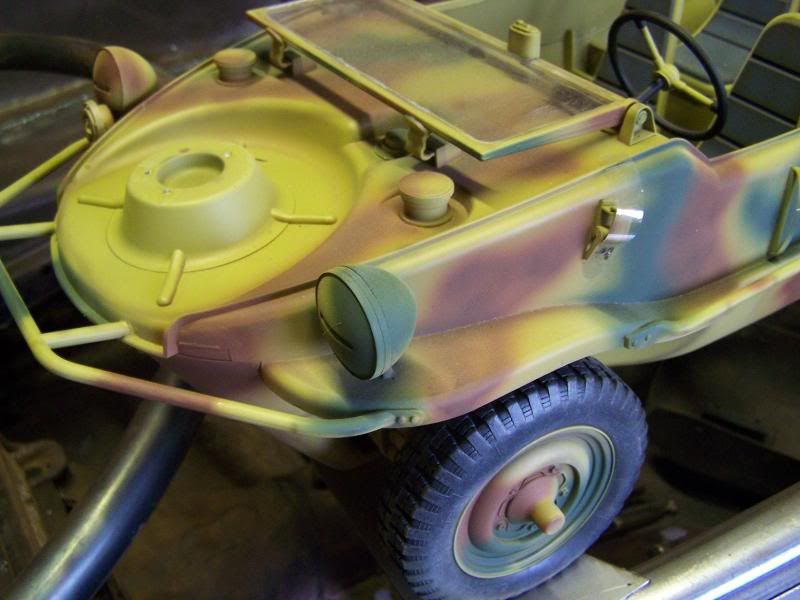

I am led to understand that some of you guys may like to take a look at my project Beetle.

Here we are.

I have been trying to build a VW166 type vehicle, using a stock Beetle as a basis and donor. Been on the project in my spare time for about six months, I recon another six months left to completion.

But, as with all these projects, I could use a bit of help and maybe some assistance with parts.

The ride height is giving me some problems, and I figured maybe I could use Trekker/Thing reduction boxes, tubes and shafts. Maybe trekker/Thing spindles up front ? could I just use the spindles, or would I need the whole front beam.

These might sound like dumb questions, but be mindful that 6 months ago I had never even took a close look at a Veedubbaya, and this is practically a vertical learning curve for me.

Some pictures for your amusement.

I don't have access to a real VW166, so have used a plastic model and whatever pictures I can get get off the Interweb, and books.

This is only a very rough working prototype, I hope to be able to make these to order in the future. If that happens, I would take the trouble to borrow a real one to copy.

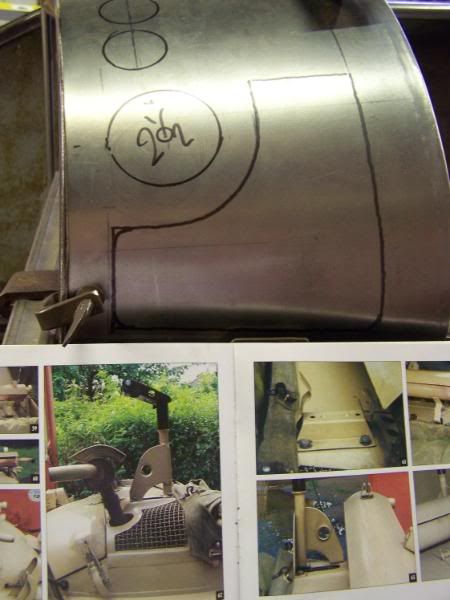

The most tiresome, but perhaps important task is a reasonably accurate assessment of the shape and size. I have done a lot of internet research, and have several books and pictures of VW 166. The most useful item is the model.

To decide the shapes I bent wire to suit the model, then carefully drew around the wire on a piece of paper. then, by disecting multiple tangents that I drew on the curves, the centre of the radius can be found. Measureing back to the arc gives a figure and that can be calcalated up to full scale. It is a little tricky because many of the shapes have several centres, and different radius, however, It is one of the few things on the project that I do have formal training at. I am a bricklayer and it is the same method that bricklayers use to set out the formers under arched openings like doorways etc.

By useing pi, the lengths of the steel sections can be calcalated into a cutting list befor bending. It is of course also possible to calcalate out the surface areas of steel, and for that matter the volume within the vessel. I guess Mr Porsche had to do that to figure the displacement to weight ratio to confirm that it would all actually float. The way I figure it - if his did - mine will !.........as long as I am fairly accurate.

Some pictures of the process.

All very laborious, But neccersary. It is much easier and cheaper to alter or throw away a piece of card or ply then a sheet of steel.

Rear bulkhead / engine firewall.