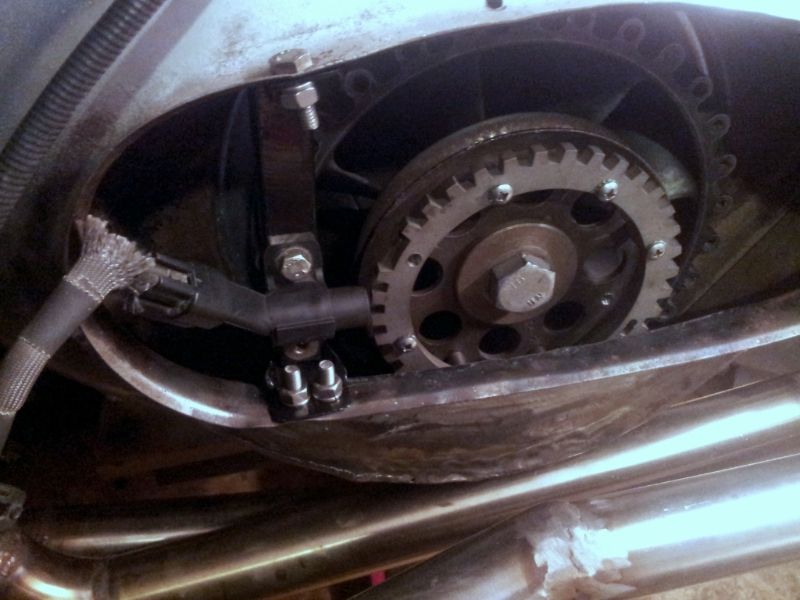

i am currently building an engine for my T34, and decided to go with MegaJolt.

i know that there is a thread about trigger wheels for the T3, but i have a different problem.

my engine have an additional pulley for an air conditioner, this pulley will not allow me to use the big trigger wheel that bolts on the the T3 aluminum fan.

i know that one can drill the flywheel and use it as a TW, but this is something i would like to avoid.

so, my problem is that i cant use any TW that bolts to the fan and i cant use a thick TW that will bolt to the AC pulley since it will rub against the steel shroud.

any ideas or thought on how to get a decent signal to the EDIS? (36-1 wheel)?

can the Megajolt work with a different system beside the EDIS?

any input will be much welcomed.

Thanks

Ravivos.