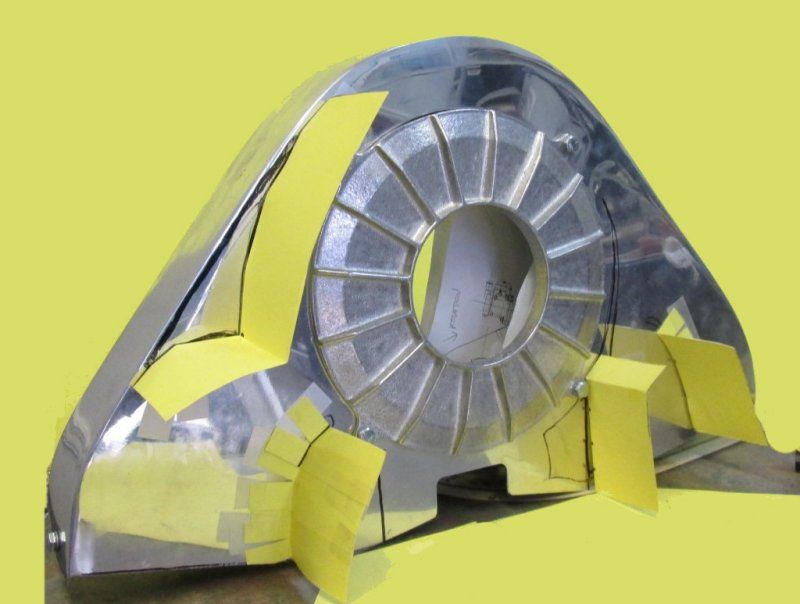

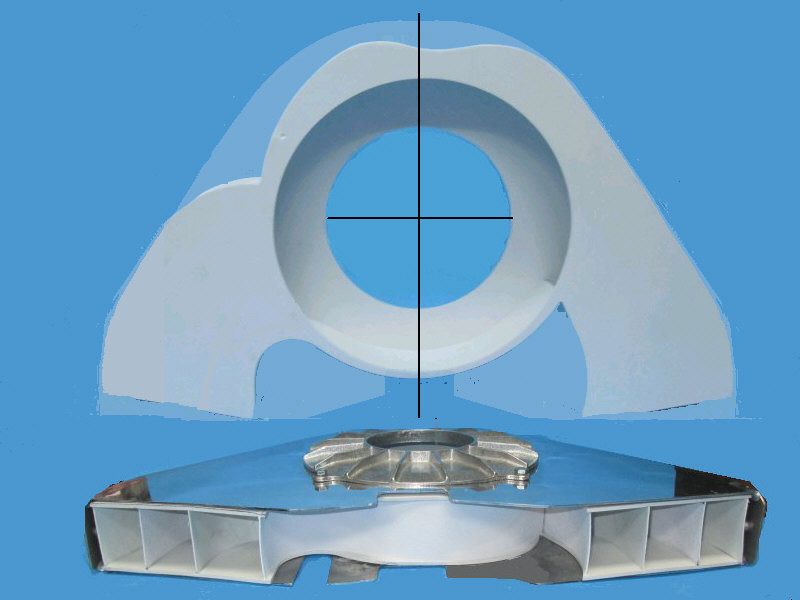

Above: A Type 1 centermount housing with paper air vanes being taped on during development tests. People usually buy this design for cosmetic reasons or for the added dual carb clearance on ech side.

AIR DUCTING THE CENTERMOUNT BLOWER HOUSING

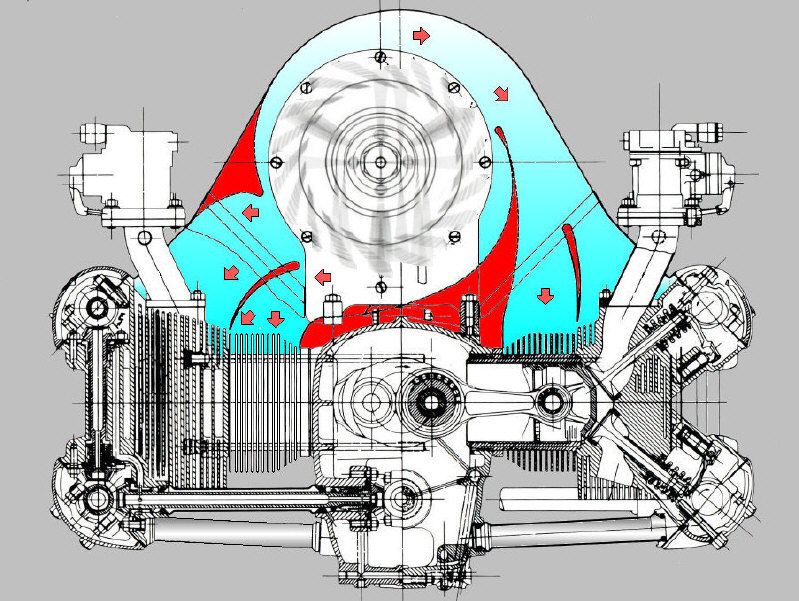

The Centermount Blower Housing is a popular item sold by many VW parts vendors but has one big drawback. It is a hollow shell and relies on the general shape of the housing -- which is about perfect for a circular turbine type blower -- to force air out of the bottom. The result is a great deal of turbulance inside the housing and less "focused" air to the cylinders.

Porsche used the "centermount" design on the four-cam Type 547 engine. The ducting pattern of the 547 blower housing was used as the model for our VW Type 1 centermount housing, insomuch as the Type 547 housing was a dual-fan configuration and drew air from front and rear.

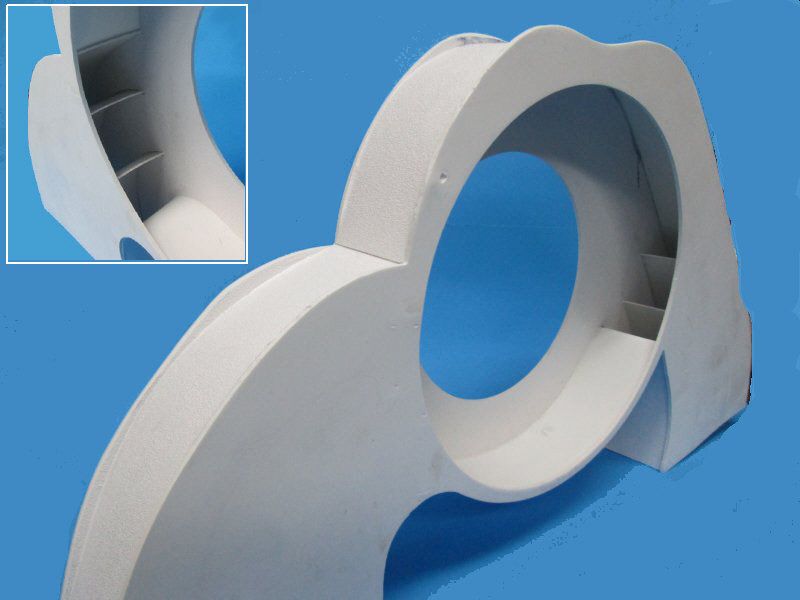

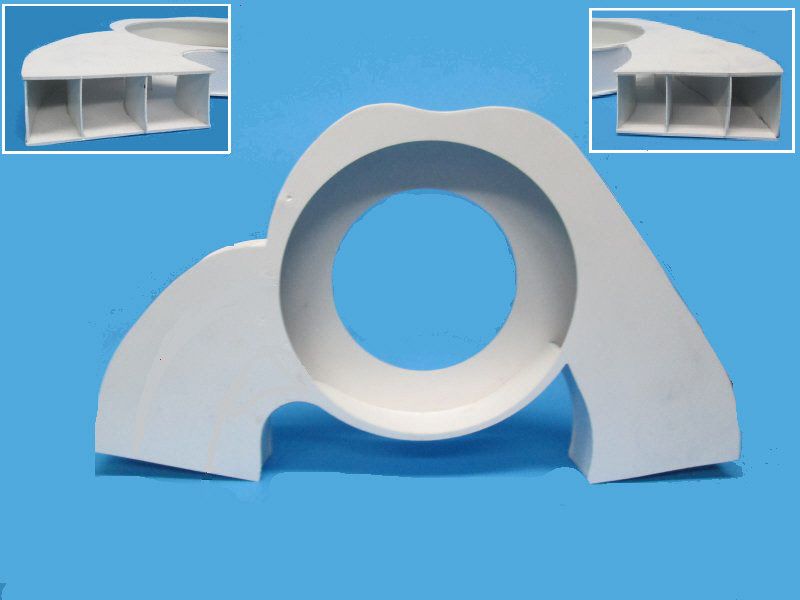

The prototype blower insert shown here is made out of thermoplastic and designed to slip directly into a Type 1 centermount blower housing.

The air is drawn into the center plenum, separated for left and right direction by flow over the contured vanes, and forced down three ducts per side to the cylinders below.

The plastic assembly is designed to slip up inside the Type 1 centermount blower housing, and be Pop-Riveted into place.

***

This is an applied design change to make the centermount housing at least as efficient as a standard Type 1 housing.

We're road testing the design with thermocouples on both heads while racing, and if successful, will be making them available for sale on the upcoming PCP Speed website.

FJC