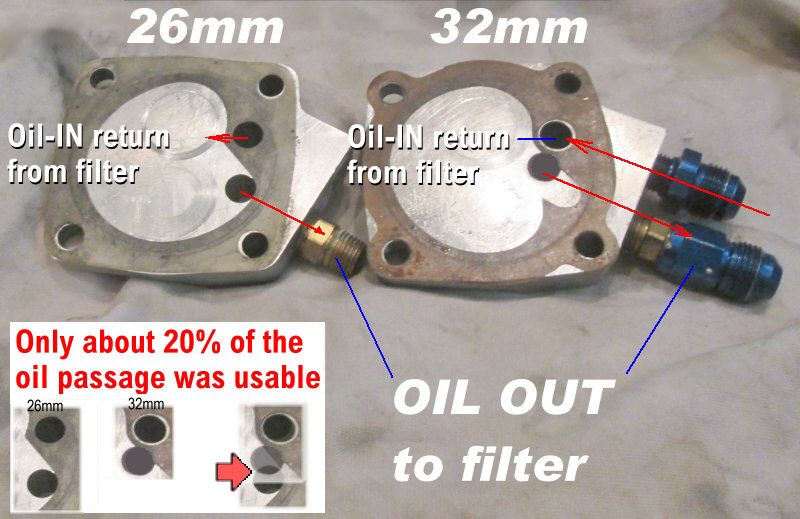

Could the oil passages be too small or restrictive?

Gentlemen,

I'm preparing our Sebring race report, but first, we have to humble ourselves and ask for help and advice on an oil temp problem.

The problem is even with an oil pump (in which the cover plate and body match), a big 8-pass cooler in the Ghia's nose with a scoop to it, we still got 300 F. oil temp within minutes on the track.

Here's the specs. 32mm pump gears on a special in-out pump pumping first to an HP-1 filter and back.

A grooved oil piston, stock pressure relief valve spring.

24-foot round trip half-inch ID rubber oil line from an oil cooler adaptor to the 8-pass cooler in the bottom of the spare tire well.

A big air inlet slot for the cooler, and vent holes in the spare tire well behind the cooler to let the air out.

A scoop on the air inlet slot.

Now, we have a mechanical oil pressure gauge on the cooler inlet to measure oil delivery pressure to the cooler as well as the VDO electric pressure sensor to the VDO oil temp gague in the dash.

The VDO oil temp sensor is in the oil pressure relief valve.

***

Observed conditions.

1. Almost immediate oil pressure at both oil pressure pickup points. 80 PSI cold. Five minutes later, a drop to about 60 PSI as the oil pressure relief valve opens. Both gauges agree on the pressure.

2. Growing oil temps seem normal in rate/time, but with a laser-aimed pyrometer aimed at the oil pump face plate, 200 degrees comes up fast, even as the in-out oil lines to the filter show 10-to-20 degrees less.

3. Heads show normal operating temps. Plugs are burning tan, timing is spot on.

4. Pyrometer reads at pump cover and around oil pump cover are higher than anywhere else.

5. Oil cooler reads 300 F. with little difference in inlet and outlet lines.

I've never seen an oil pump as a big contributor to oil temp overheating. This is a strange one.

FJC