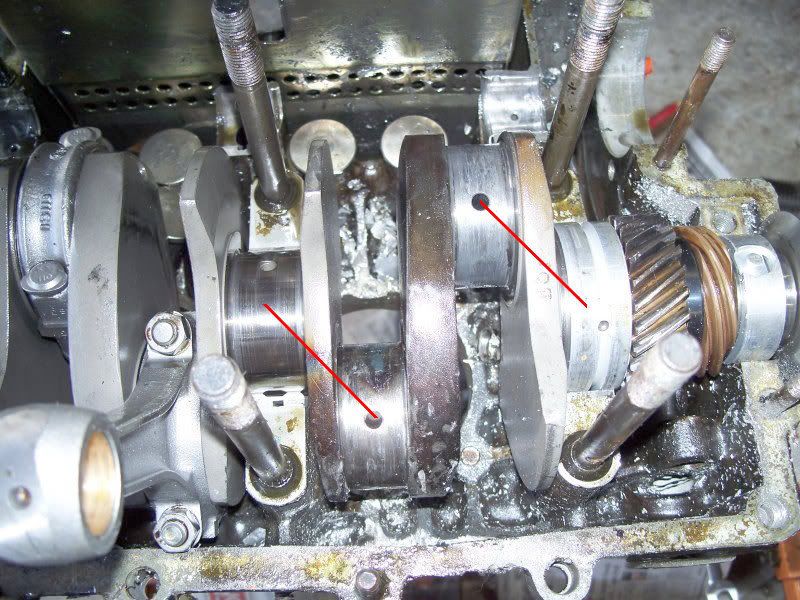

Rod bearing throws on #2 and #4 are fed by seperate drillings.

Strange Rod Bearings Failure

This engine died of #4 rod bearing failure and separation (and the usual massive damage that goes with it) without turning two full miles on the track. And the #2 rod bearing was about to go, worn down to a thin sliver. In that this is the first time I have ever seen this specific type of failure in one of my own engines, I hope someone will come up with a clue.

Specs

AS41 case, line-bored twenty over

Windage tray

Oil "suction" pickup and dished oil plate. No strainer

Case oil pickup tube seated and tight

All new Mahle bearings

EMPI 74mm counter weighted crank (new out of box)

Stock VW rods (Bugpack) used but balanced and rebuilt

85.5mm Mahle piston and cylinder set

A.J. Sims heads, 46.4cc combustion chambers, 9.4:1 compression

Auto Linea G03, Dual springs

40mm Intake Valve, 35mm Exhaust Valve

A.J. Sims cam & hardened lifters

Cam LBC 3-108*LC

Lift (1:1) 461, Duration 290

32mm full flow Oil Pump (direct pump to HP1 filter)

8-Pass remote oil cooler fed by adapter from case top, electric fan-cooled

Grooved oil pressure relief piston, stock spring

Ungrooved oil pressure control piston, stock spring

Oil: 15w40 Castrol Tection Diesel with ZDDP

Carbs: EMPI HPMX copies of Weber 44IDF's

Shop run-testing was good, oil pressure all in spec. Throttle response good. At track test day, we get rod bearing knock right away. While in paddock revving engine (3000rpm+) to listen for knock, #4 rod blows through top of case.

Tear down reveals cam broken into four pieces, #4 rod seperated at bolt side, but bolt is found intact, nut stripped right off threads and crushed, and #2 rod bearings almost worn away.

All mains were good, and rod bearings on #1 and #3 excellent. The only other bearing damage was from dust-fine case fragmentation bits that had only a couple of seconds to try and circulate to the bearings.

Blowing air through case oil passages revealed no stoppages. and removing the set screws from the crank drillings and poking long steel probes inside finds that the interior crank drillings are in fact there.

How can two rods, fed by different crank passages, die this fast?

Any suggestions are welcome.

FJC