Mechanical vs Electric Fuel Pumps

VW and Porsche used mechanical pumps for all their carburetor-based street cars from first to last, and the factory-issue mechanical pumps pushed many a competition VW or Porsche around many a race track.

So, why bother with an electric pump if it wasn't the factory's choice to begin with? To understand the answer to that, we have to start with the mechanical pumps themselves.

The mechanical fuel pumps used on the pre-40 horse VW and throughout the push-rod four cylinder 356's life span were precise mechanical devices. You remember these. They were mounted to the left side of the engine case, below the distributor, as you looked into the engine compartment.

VW and Porsche demanded a plus or minus fuel pressure fluctuation limit of 10% on these pumps, a self-pressure regulating ability to keep pressure right for the stock carburetor on the model it was intended to feed, and long life service reliability.

The VW, pre-A and A type 356's (the DVG pumps) could have their pressure output changed with gaskets or spacers between pump and engine case, to lengthen or shorten push rod travel, a technique that continued on with the VW 40-horse case.

But Porsche wanted even more fuel delivery and pressure control for its new 2bbl Zeniths and Weber-type twin-choke 40PII Solexes, and with the B and C series cars, began using the APG pump which was totally self contained for it's diaphragm movement, and spacers or gaskets were no longer necessary to correct its output.

But, with the four-cam Type 547 racing engine introduced in 1954, Porsche decided to use dual electric Autopulse pumps. These pumps fed a common filter connected to the carbs, which initially were twin-choke Solexes or Webers.

Electric pumps primed the carb float bowls fast, and provided steady fuel pressure with no mechanical pushrod "pulsing," a condition that if not dampened by a surge chamber inside the mechanical pump, can constantly "tap" the float, causing it to bounce back against the needle and seat valve, and wear it so much that float bowl overflow and erratic flooding occurs.

The electric pumps were also useful in emptying the fuel tank after a race for storage, or if the tank needed to be removed for modification or servicing.

A serious safety consideration is having a means of turning off an electric pump after a crash, because it will continue to pump as long as it gets power. The most simple solution is having a fuel pump switch separate from the ignition that the driver can turn off -- if he is able. Inertial switches that shut off in the event of a collision or inversion are available.

http://www.breezeautomotive.com/details ... &cat_id=49

http://s2.pegasusautoracing.com/2009/043.pdf

Another electric fuel pump consideration is location and mounting. Electric pumps "push" fuel just fine, but do not "pull" fuel well. That means the right place for an electric pump is near the fuel tank, and preferably where gravity feeds the fuel line to the pump.

This pump is alongside, not below the fuel tank, but has enough power to suck priming fuel a short distance.

A common question you hear on all the forums is "Will the mechanical fuel pump feed my 48IDA Webers from my house to the grocery store?" Actually, yes. Fuel volume is not a problem with a good VW mechanical fuel pump.

Holley Blue pump and regulator

The most overlooked fuel system part seems to be either a fuel pressure regulator, or filter.

The VW mechanical fuel pumps output on an average of 3 psi to 5 psi. OEM Solexes are very happy with that pressure range. But Weber and other makes need more precise pressure. For instance, Weber states that 3.5 psi is maximum for their float systems.

The popular Solex-Kadrons need even less, down to 1.5 psi.

And yes, there are many guys running stock VW pumps with both and have had little trouble. That's because with either Webers or Kadrons, the stock pump is close to what's needed, and the carbs (depending on condition) are tolerant enough to suffer a small overpressure.

But, a bunch of guys with stock pumps who have performance carb trouble and tuning problems and absolutely cannot figure them out have overpressure problems. They experience on-again off-again idle, acceleration, and even steady-state cruise trouble that seems to be electrical or jetting, vacuum leaks, or even sticking valves.

The point here is if you run a set of performance carbs, put a regulator between them and the fuel pump.

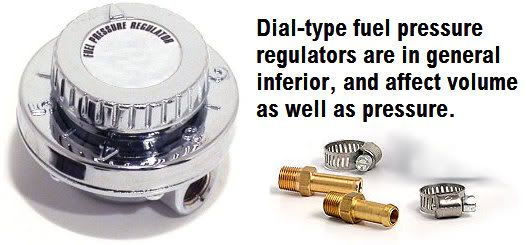

Regulators come in two basic forms, the simple dial-type that is suitable for street applications, to the more complex valve-type (such as the Holley already shown) that regulates pressure without affecting volume.

And dial-type or valve-type, your must measure the output of the regulator with a gauge. Dial-types sometimes have numbers on the dial that seem to represent psi, but do not trust them.

Finally, there is the fuel filter. The filter must be large enough to provide volume and flow, restricting neither. The glass see-through filter types screw together, and sometimes get loose and leak. As a rule, do not use them. I like the disposable clear plastic filter because it shows fuel flow, and the contaminants it catches.

We didn't get into fuel line types, sizes, or connectors this time -- that's coming up.

FJC