How to fix your Scat DragFast shifter.

Posted: Mon Apr 07, 2008 7:54 pm

Ok, so I finally was able to get my dragfast shifter to work correctly.

The problem of jumping into reverse seemed to go away when I used the stock shift plate, at least with the car not moving. When driving, it still jumped into reverse. Not only that, but it was next to impossible to find third gear driving. I'd sit there, rolling around for 10 seconds between the gears like an idiot until I'd lose so much speed I'd just shift back into second (or reverse )

)

Removing the plate helped find third gear, but the reverse problem wouldn't go away. But now FIRST was hard to find! I didn't want to sit at the stoplight dicking with it, I just want all my gears!

I did all the recommended things to help aid the shifting. Replaced the shift rod bushing (only a couple of years old, but what the heck) cleaned, polished and regreased the shift rod, and rebushed the cage at the trans coupler (the bushings were the original stock, but still in OK shape).

Still no gravy. Same problems as before. What do I do? I was ready to just slap the stocker back in.

I got tired of hearing,

"Dude, you should have gotten a Berg, man!"

No kidding. I'm sure I'd be very happy with a Berg, I haven't heard one bad thing about them. The problem is that Berg knows this too. So we end up with the Gucci of VW shifters, yours to own for only $250.

But what about the hapless people like me that are stuck with a hundred dollar shifter we can't use, and nobody wants? My folks got me this for my birthday, it would suck to throw it away. It seems really nice, and when it works, it works great!

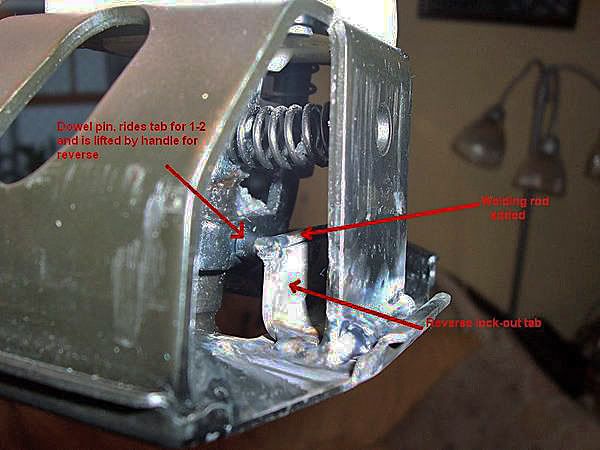

So I lifted up the boot and started paying attention to the mechanism inside as I played with the shifter. A common fix that people do to these is bend the reverse lockout tab inward. I tried that, and it didn't really do anything, and now I understood why. The problem is that the tab is too short! Even standing straight up, the lockout pin (it looks like a crank dowel pin) only has to move up about 1/16" to clear the tab, and move into reverse! Bending won't help too much, as it will only make this distance shorter! That's why the shifter hops out into reverse so easily, whether you want it to or not. So why have the lockout handle raise almost a half inch? There's so much travel but it obviously isn't being used.

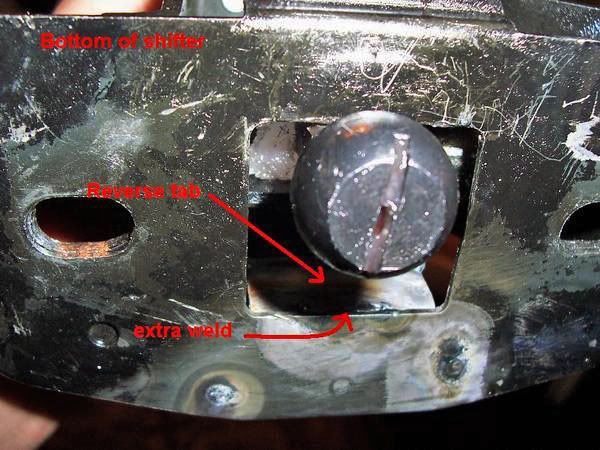

So I decided to make the tab taller. It's kinda in the guts of the shifter, and not easy to get at unless you feel like busting it apart. I finally decided to take a small bit of 70S-2 welding rod, 3/32" diameter, and weld it to the top of the tab. We use the 70S-2 to weld almost all the steel projects in the shop. It's very stiff stuff, and there were plenty of scraps in the bin. I figured the worst that could happen was that I'd end up with a crappy shifter. I had nothing to lose.

It worked!

Now I actually have to lift the handle almost all the way to get into the reverse slot. No more hopping!

Now came the second problem, the finicky first and second gear. They would go if I would very softly try to locate them. If I tried to go all the way left, it would get stuck in neutral, and not move up or down for love or money. So I looked at it some more, and found the problem.

The whole reverse tab would actually tilt out of the way when pushed against! Remember, this tab is what the little dowel pin rides against to stay in the 1-2 slot. I just fixed it so the pin can't hop over anymore. But now, even with the slightest pressure pushing left on the shifter, the whole tab would bend over and the shifter would get stuck in between slots!

So I took it off again, and welded the tab to the plate from the inside. Now it's not going anywhere!

So I put it back in, and now it works. FLAWLESSLY. I was so happy. What I thought was a piece of crap now feels like it was made by a swiss watchmaker.

You're thinking, "I shouldn't have to mess with it out of the box. For a hundred dollars, it should just drop in and go." You're right. But I didn't want to just throw this away after all this money was spent. I didn't want to put the stocker back in, and I wasn't going to throw another wad of cash at a Berg either.

So all it took to make it work was a bit of tweaking. I guess you could look at it this way... a Schadek is the best oil pump for the VW, but they don't come blueprinted!

Stoked.

The problem of jumping into reverse seemed to go away when I used the stock shift plate, at least with the car not moving. When driving, it still jumped into reverse. Not only that, but it was next to impossible to find third gear driving. I'd sit there, rolling around for 10 seconds between the gears like an idiot until I'd lose so much speed I'd just shift back into second (or reverse

Removing the plate helped find third gear, but the reverse problem wouldn't go away. But now FIRST was hard to find! I didn't want to sit at the stoplight dicking with it, I just want all my gears!

I did all the recommended things to help aid the shifting. Replaced the shift rod bushing (only a couple of years old, but what the heck) cleaned, polished and regreased the shift rod, and rebushed the cage at the trans coupler (the bushings were the original stock, but still in OK shape).

Still no gravy. Same problems as before. What do I do? I was ready to just slap the stocker back in.

I got tired of hearing,

"Dude, you should have gotten a Berg, man!"

No kidding. I'm sure I'd be very happy with a Berg, I haven't heard one bad thing about them. The problem is that Berg knows this too. So we end up with the Gucci of VW shifters, yours to own for only $250.

But what about the hapless people like me that are stuck with a hundred dollar shifter we can't use, and nobody wants? My folks got me this for my birthday, it would suck to throw it away. It seems really nice, and when it works, it works great!

So I lifted up the boot and started paying attention to the mechanism inside as I played with the shifter. A common fix that people do to these is bend the reverse lockout tab inward. I tried that, and it didn't really do anything, and now I understood why. The problem is that the tab is too short! Even standing straight up, the lockout pin (it looks like a crank dowel pin) only has to move up about 1/16" to clear the tab, and move into reverse! Bending won't help too much, as it will only make this distance shorter! That's why the shifter hops out into reverse so easily, whether you want it to or not. So why have the lockout handle raise almost a half inch? There's so much travel but it obviously isn't being used.

So I decided to make the tab taller. It's kinda in the guts of the shifter, and not easy to get at unless you feel like busting it apart. I finally decided to take a small bit of 70S-2 welding rod, 3/32" diameter, and weld it to the top of the tab. We use the 70S-2 to weld almost all the steel projects in the shop. It's very stiff stuff, and there were plenty of scraps in the bin. I figured the worst that could happen was that I'd end up with a crappy shifter. I had nothing to lose.

It worked!

Now I actually have to lift the handle almost all the way to get into the reverse slot. No more hopping!

Now came the second problem, the finicky first and second gear. They would go if I would very softly try to locate them. If I tried to go all the way left, it would get stuck in neutral, and not move up or down for love or money. So I looked at it some more, and found the problem.

The whole reverse tab would actually tilt out of the way when pushed against! Remember, this tab is what the little dowel pin rides against to stay in the 1-2 slot. I just fixed it so the pin can't hop over anymore. But now, even with the slightest pressure pushing left on the shifter, the whole tab would bend over and the shifter would get stuck in between slots!

So I took it off again, and welded the tab to the plate from the inside. Now it's not going anywhere!

So I put it back in, and now it works. FLAWLESSLY. I was so happy. What I thought was a piece of crap now feels like it was made by a swiss watchmaker.

You're thinking, "I shouldn't have to mess with it out of the box. For a hundred dollars, it should just drop in and go." You're right. But I didn't want to just throw this away after all this money was spent. I didn't want to put the stocker back in, and I wasn't going to throw another wad of cash at a Berg either.

So all it took to make it work was a bit of tweaking. I guess you could look at it this way... a Schadek is the best oil pump for the VW, but they don't come blueprinted!

Stoked.