I have been hard at work on my heads. Here are some pics of what I've been up to. I also have a question...

On the exhaust port, Should I be opening it up to the size of the copper gasket or the size of the 1 1/2" ID Stub pipes? Do I touch the guide boss or just smooth it? I'm trying to stay away from the short radius.

On this intake port pic, it looks like I removed too much from the intake boss or chipped, but I didn't-its some weird shaddow.

almost untouched port on left, Unfinished port on right.

Look how bad the manifolds normally line up!

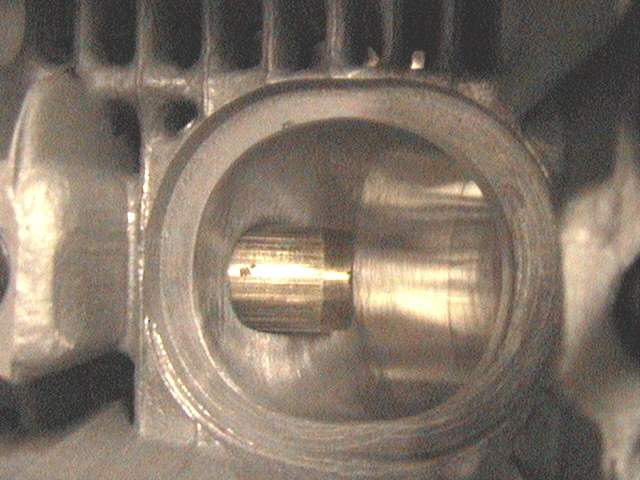

Exhaust port, mostly polished, but unfinished. This is the guide boss I'm questioning what I should do on..

This is just a few mins worth of work. I hope to have most of them complete later tomorrow. I'm using 6" shank double-cut carbide burrs. A good supplier is PalmAbrasives. They run about $14 per bit. I will finish with cones and flap wheels.

What should I do about the guide boss? I've been reading HAM Inc's posts and they AWESOME, exactly the info I've been looking for!

Thanks!

-Bobby

[/img]