Page 7 of 12

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Sat Sep 30, 2017 7:26 am

by Clatter

That's why it's important to not listen to most experienced old-timers..

They say stuff like_

"Oh, you don't have to do all that"

and

"It'll work fine"

and

"Just put it together".

Those days are gone.

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Sat Sep 30, 2017 7:27 am

by Clatter

"That's your size"..

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Sat Sep 30, 2017 2:22 pm

by analogtherapy

Clatter wrote: ↑Sat Sep 30, 2017 7:24 am

See why this is so much harder to do now?

Used to be that you just put these together!

Now, you have to check, and often adjust, everything.

I'm really starting to understand that now

But, new bearings did the trick (John you're a genius)! Just got them in the mail, mocked em up, and it was a huge difference. I still need to do a mockup with both crank and cam installed, and see how the crank rotation feels now, but outlook is good!

By the way: the original cam bearing set I got were Kolbenschmidt, the 2nd set were Mahle. There was a noticeable difference in weight and finish between the two brands, with the Mahle being heavier and having a more polished (shiny) look. Both were made in Brazil. Maybe this was just the luck of the draw, but the Mahle's did seem to have an overall higher quality to them even before fitting them up. Just my .02.

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Thu Oct 05, 2017 3:11 pm

by analogtherapy

Question: Would you run this fan if it were yours?

Awhile back I had taken my crank, flywheel, etc (including this fan) to be balanced, and this is how the fan was balanced. I was shocked when I picked it up, but I'm also pretty ignorant when it comes to this kind of stuff (maybe this is acceptable?) so I just set it aside to come back to it later. I've started thinking about it again. So, is this fan structurally compromised? It seems like an awfully lot of metal removed to me...

Would you run it as is, or get a new one?

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Fri Oct 06, 2017 3:51 pm

by raygreenwood

No...DO NOT run that....whoever did that is an absolute dumbass. The balance weight is crimped on the inside rim of the steel pulley. Ray

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Sat Oct 07, 2017 11:00 am

by analogtherapy

raygreenwood wrote: ↑Fri Oct 06, 2017 3:51 pm

No...DO NOT run that....whoever did that is an absolute dumbass. The balance weight is crimped on the inside rim of the steel pulley. Ray

Thanks Ray. Your reaction just confirmed my fears. Looking for a type 4 fan now...

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Wed Oct 11, 2017 9:44 am

by analogtherapy

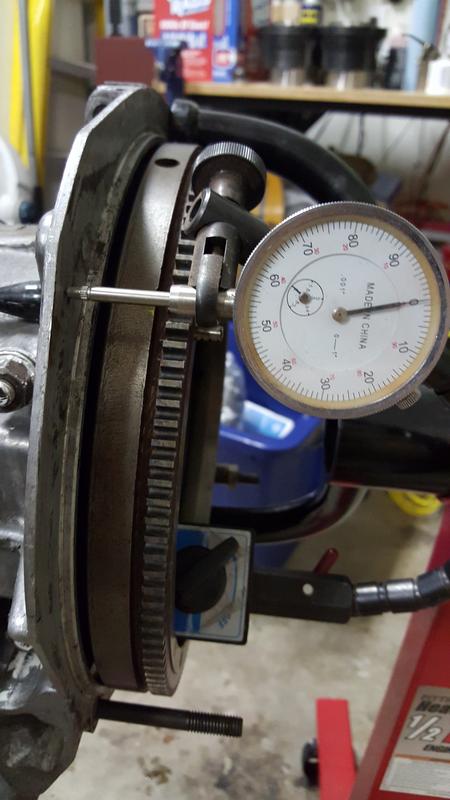

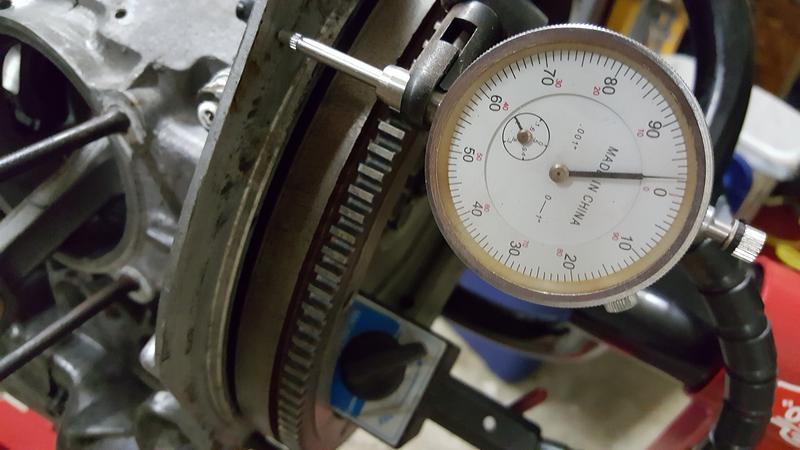

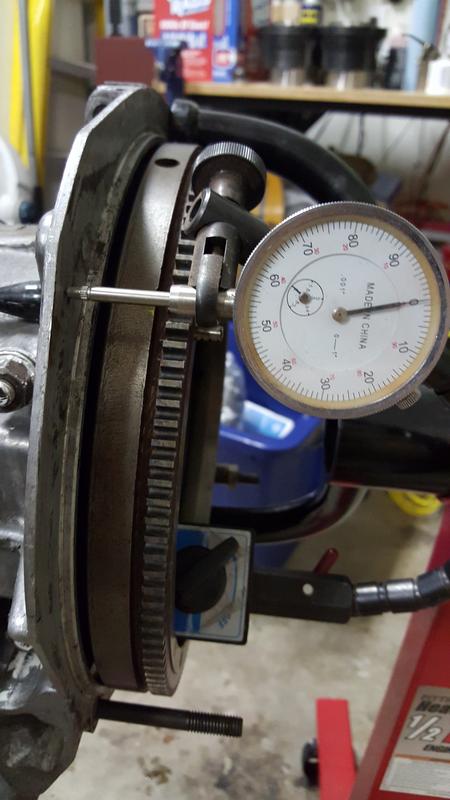

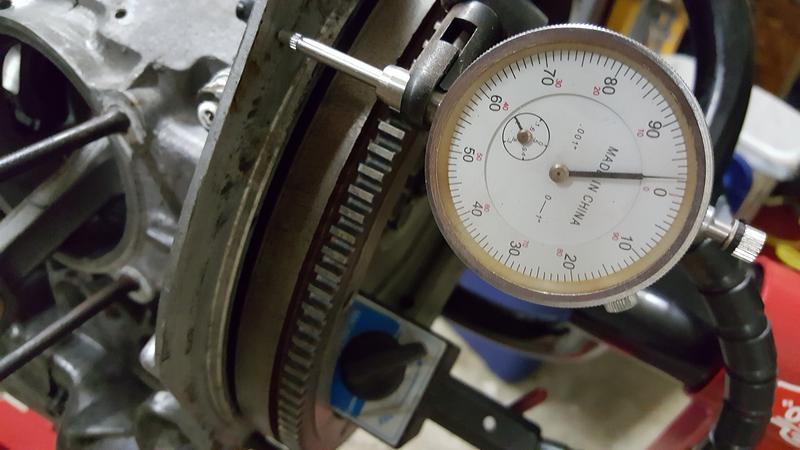

Moving on to crankshaft end play...

I've repeated this a number of times, and...if I'm reading this correctly...I've got end play of .0025 (I zeroed the dial with the flywheel pushed close to the case, then pulled away from the case). Each time, it measured riiight between the .002 and .003.

Is this too tight to proceed?

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Wed Oct 11, 2017 3:27 pm

by Clatter

If that was how your fan was balanced,

I wouldn't be trusting their job on the crank/flywheel, etc.

Best be getting all of that back out and apart for a re-balance with your new fan..

Sorry,

But the truth hurts sometimes.

Good thing you caught it!

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Wed Oct 11, 2017 3:37 pm

by Clatter

WRT the end-play,

Being on the tight side is good, but requires diligence.

Ultimately, tight is good,

it allows a good long time before everything pounds itself out to loose.

On the other hand,

a smart shop never sends things out on the tight side of spec,

because customers never break in properly.

Are you are going to be in a hurry, and out there running it hard, before it's broken in and dialed on your wide-band?

Then, if so, go looser.

There is a lot at stake if you stick your mains tight..

However,

If you are judicious in your love/care, a tight setting can make the thing possibly last a lot longer.

Most people stick their old gummy distributor, with one broken spring, and holed vacuum can on their new motor.

They put on their old clogged injectors, stiff regulator, and even their half-clogged fuel filter.

Their new motor never has a chance..

After all of this rebuild pain, who can blame them? Enough already! We want to go camping!

That's why the old mechanic always goes to the loose side of spec with the end-play.

They know that the motor will be run hot and hard right out of the gate,

And this helps with CYA..

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Thu Oct 12, 2017 10:57 am

by analogtherapy

Thanks Clatter sir. I do intend on treating this engine right. I'll revisit the end play once I'm able to accurately measure my shims...

Moving forward a bit: I've measured my piston height against cylinder height, and (using feeler gauges) I'm at .026":

(I did have this cyl. bolted down using sockets, but I had just removed them prior to this pic)

I've only done one right now, starting with #3. My heads are from Len, and have .8mm raised step in the cylinder registers.

So if I understand this correctly...

.026 in = .66 mm

.8 mm + .66 mm = 1.46 mm, which is .057 in, which is within the .04 - .08 spec mark mentioned in Tom Wilson's book. Assuming all pistons/cylinders are the same (FYI, I will be measuring each individually), then this is a good number and I can move forward on figuring out my CR, right?

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Thu Oct 12, 2017 12:37 pm

by analogtherapy

OK, I think all this reading is finally starting to sink in!

So, continuing from above (these are just assumptions at this point, based solely on the #3 measurements):

If my deck height is .057...(or 1.46 mm)

Bore: 94 mm

Stroke: 71 mm

Combustion Chamber CC's: 64.5 (49.5 CC's from the head, 15 CC's from the piston dish)

Then CR = 7.6, which is right in line with aircooled.net's statement that the webcam 142 runs best with a CR of 7.5 - 7.75:1 (which is what I'm shooting for).

We'll see if actual measurements end up the same, but I think I'm finally wrapping my head around this stuff.

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Fri Nov 03, 2017 8:11 am

by analogtherapy

I finally got some time to set up and take some deck height measurements, and I'm not sure what I should do next.

Here is what I found:

#3

Piston/Cylinder DH = .010 (.25mm)

Total DH = 1.05mm

CR: 7.8

#4

Piston/Cylinder DH = 0

Total DH = .8mm

CR: 8

#1

Piston/Cylinder DH = .011 (.28mm)

Total DH = 1.08mm

CR: 7.8

#2

Piston/Cylinder DH = .022 (.56mm)

Total DH = 1.36mm

CR: 7.6

HAM Heads step + .8mm to DH

Bore = 94

Stroke = 71

CC's 64.5 (15cc piston dish + 49.5cc head)

So which is the better fix...cylinder shims, or sanding the piston tops?

How to I deal with the variances between all 4 (specifically #4 having 0 DH between piston and cyl, and #2 having the greatest DH at .022)?

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Fri Nov 03, 2017 9:38 am

by Piledriver

Neither, yet.

First you need to see where the variance comes from.

In the process of rebuilding rods, they inherently get shorter, and sometimes the end results vary.

Sometimes the crank throws are offset a tiny bit...

Sometimes the jugs are slightly different lengths.

Swapping the rods around frequently helps minimize deck height variations.

You should be able to measure the jugs directly.

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Fri Nov 03, 2017 11:24 am

by analogtherapy

OK, thanks Piledriver.

Here's what I got...

Cylinders:

#3 = 3.588 in

#4 = 3.584 in

#1 = 3.585 in

#2 = 3.583 in

Pistons:

#3 = 2.520 in

#4 = 2.519 in

#1 = 2.522 in

#2 = 2.519 in

Now I'm just trying to make sense of these numbers

Re: T4 Tear Down / Rebuild in Jax FL

Posted: Fri Nov 03, 2017 11:47 am

by raygreenwood

The real key...is too mix and match rods and pistons to get numbers as close to the middle as possible...and then....CC the deck area, CC the chambers...and then figure out if an how much its actually messing with compression.

For example....meaning designed for.... deck height is supposed to be .045"....and due to variations in piston height and rod center to center machining....I was getting a variation in one or more deck height of .010"....which could mean a deck of .035" (not safe in some engines)...or .055" (not excellent but not horrible)...and due to the combustion chamber shape/volume or differences that valve margin/protrusion might make from chamber to chamber....if the compression ratio difference was UNDER 0.1.... meaning say instead of 8.5:1 compression....with that extra .010"... I had 8.48:1 or 8.45:1 compression....I might not worry about it much.

Be sure to check the exact length from case seat to heat seat area of each cylinder as well. Measure in at least 6 spots around the cylinder..and look for high spots on the case seating area of the cylinder, burr areas on the case etc. Anything that may skew the deck height measurement. Ray