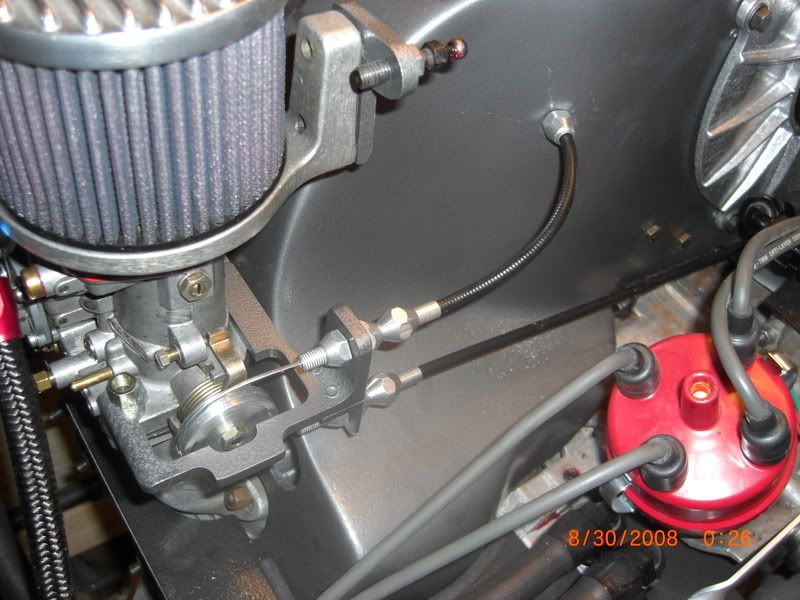

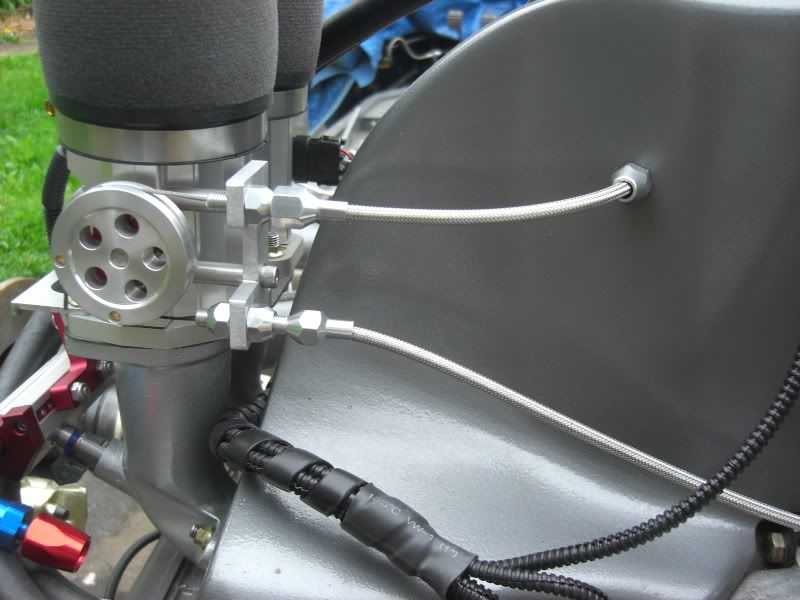

Very nice. Keep us posted.slowtwitch wrote:Well, I finally got my camera back and took some pics of my modified linkage setup. It still needs a little fine tuning, but, seems to be working nicely.

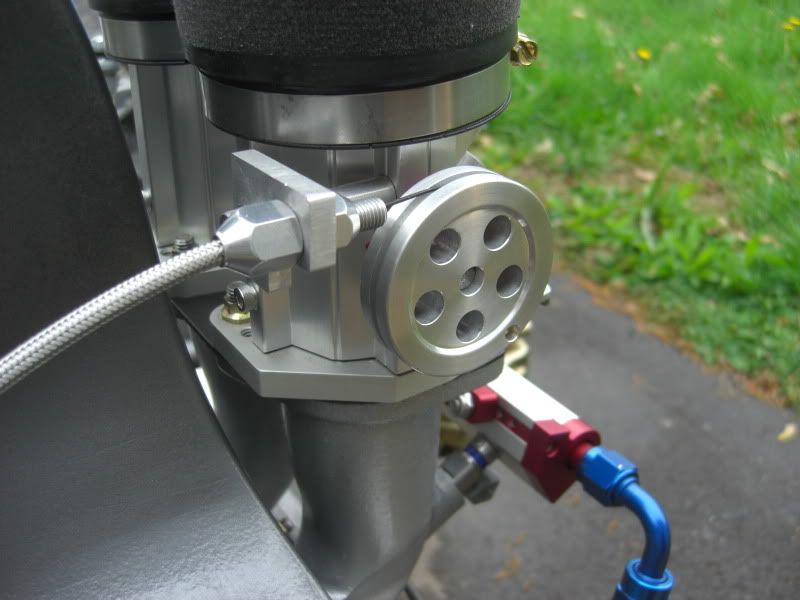

a closer look....Although, it works pretty freely, I may still go a bit bigger on the pulleys (it was the only stock I had). Gawd, that hex bar stuff is ugly

and the front side, I may change this out, with one that has a bend in it. We'll see when it comes time to install this thing

Project---Split cable pull linkage

-

The Fix

- Posts: 168

- Joined: Thu Mar 17, 2005 9:25 pm

- fusername

- Posts: 6806

- Joined: Sun Jan 28, 2007 11:26 am

that pull box is crazy! I gonna try to make a dual stock carb setup for a type 1 motor, and I was planning on using a home brew cable setup to run it, as the plan was to do a dirt cheap performance motor, hence the dual 30pict 2 carbs. sadly one has shafts worn to poop, so i may try to bush that using hand tools, probably will end out with a paper weight tho.

if i hadn't got a good deal on a hex bar, i would have done this for my 2.0 motor.

if i hadn't got a good deal on a hex bar, i would have done this for my 2.0 motor.

give a man a watch and he'll allways know what time it is. give him two and he can never be sure again.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

-

jjjtttggg

- Posts: 72

- Joined: Thu Mar 01, 2007 12:14 pm

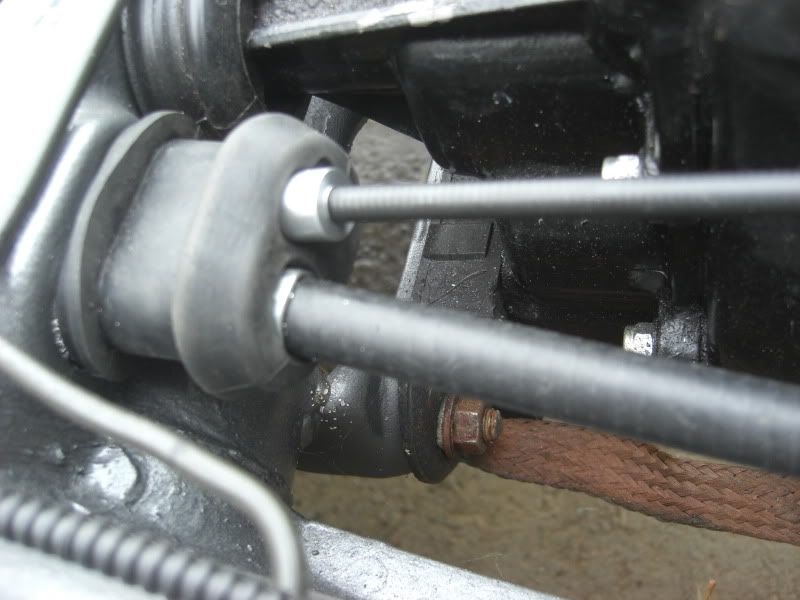

I know this is an old thread but I happened upon it researching carb synching. Comes up first when you search 'Carb Sync'. My son and I built a split cable linkage that isn't as pretty as the ones in this thread and its T1 not T4, but it works, so I figure I'll share...

I made a little splitter bracket from a piece of an angle shelf mounting bracket. Then we mounted a piece of angle iron in the middle of the engine in line with the throttle cable. In the angle iron, I put a couple of threaded holes for bicycle barrel adjusters, then a pair of bicycle brake cables to the carbs. I had a couple of transition pieces machined to go between the carbs and the manifolds with a stop for the cable housing. Needed stiffer than stock return springs to pull the cables back to idle, but other than that it works exactly as planned.

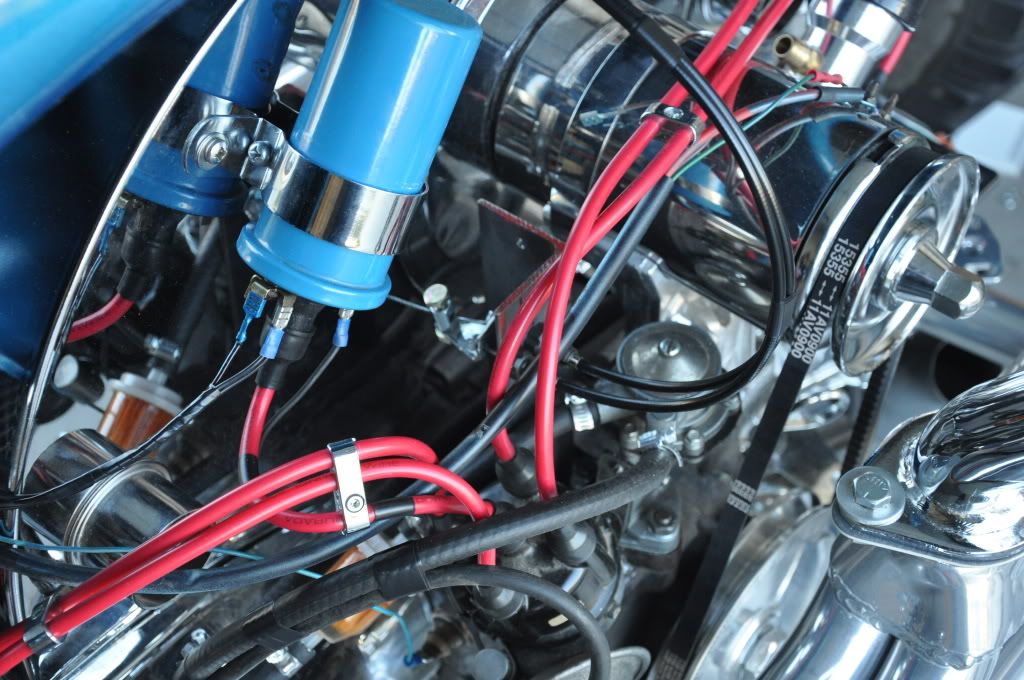

Here are some pics . . . In this first one, just between the blue coil and the two red plug wires you can see the throttle cable coming in from the left to the splitter piece, and then the piece of angle steel coming up from the middle of the engine for mounting the barrel adjusters for the cables. At some point, I’ll need to pretty up the edges/corners of the angle piece and get some paint on it. . .

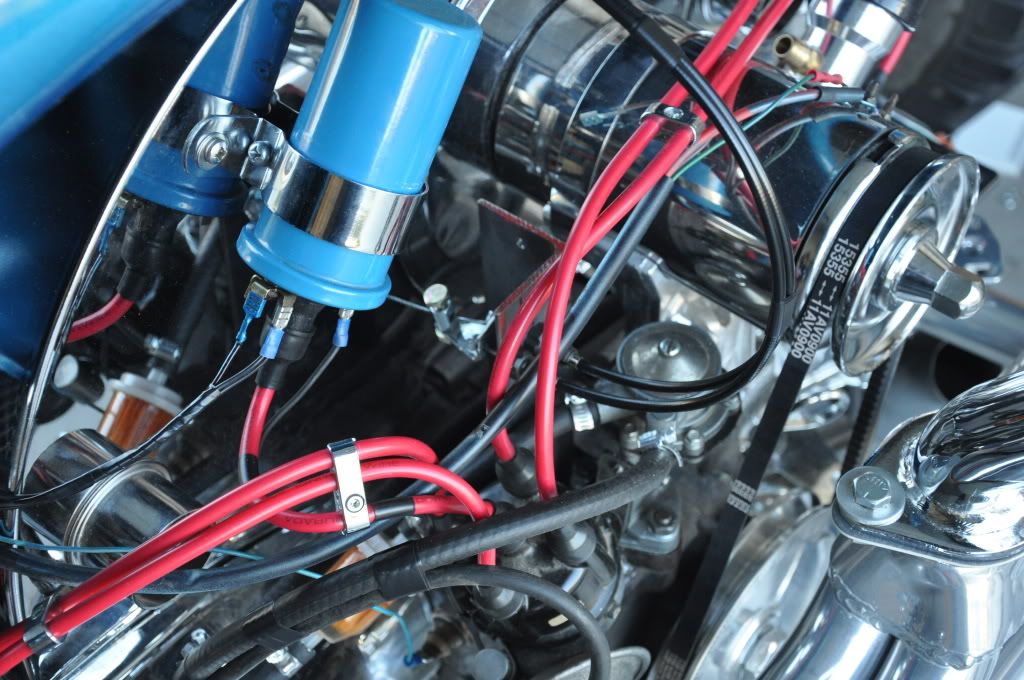

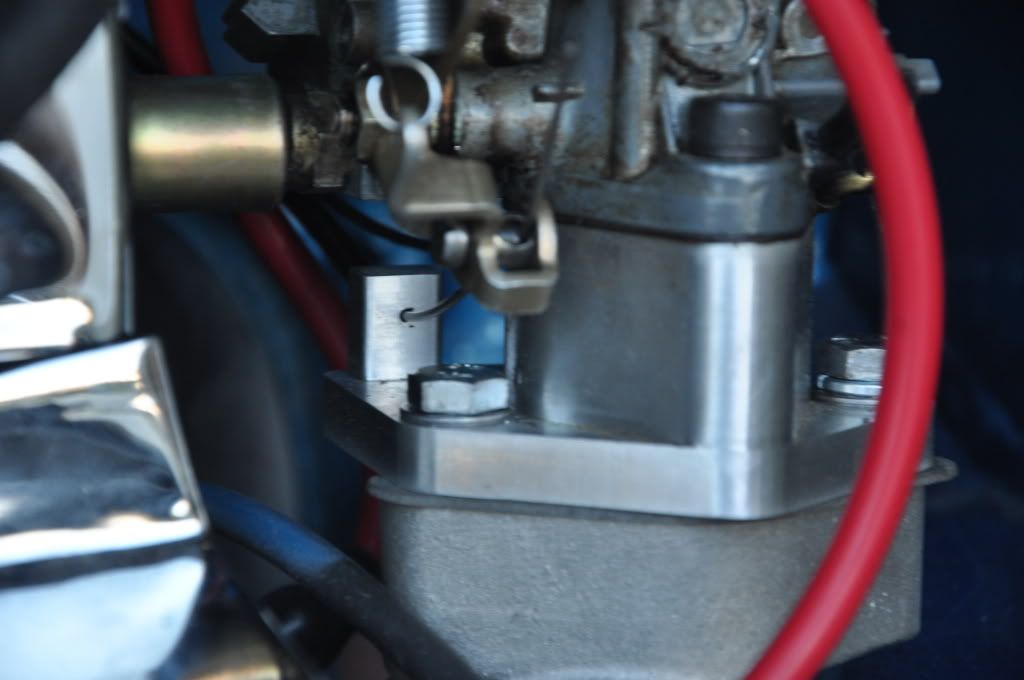

This next pic is a closeup of the same spot. Here you can make out the barrel adjusters (just behind the plug wires) for balancing/synchronizing the two carbs so their throttle plates are open the same amount and they both draw the same air mid throttle. . .

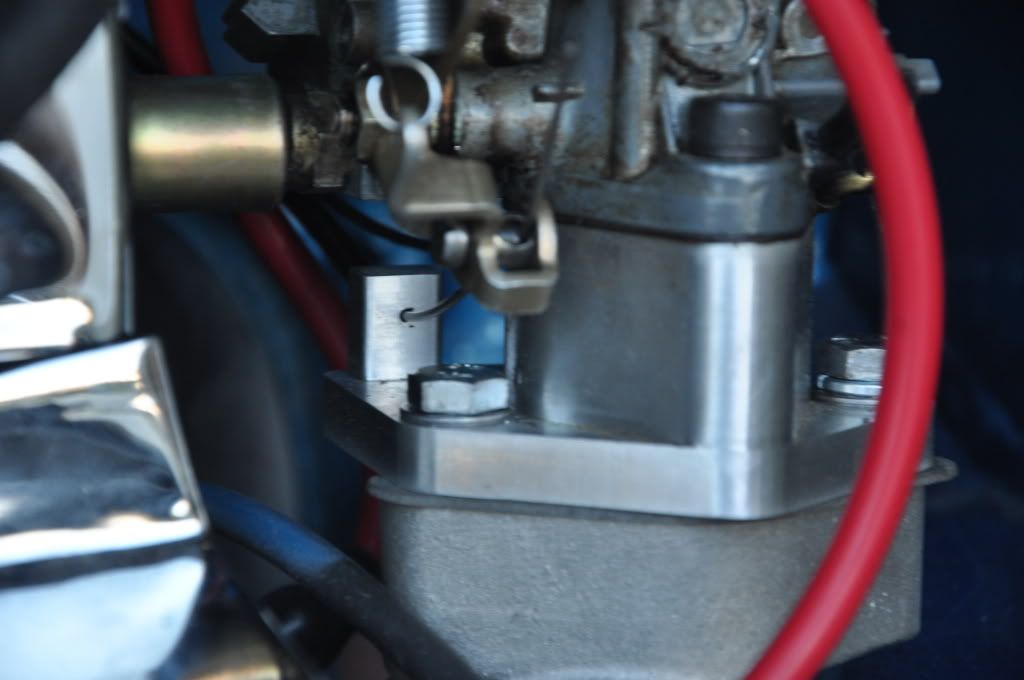

Finally, the transition piece: The shiny aluminum piece in the middle is it. You can just barely see the bicycle brake cable housing coming in from the back to the stop at the lower left of the transition piece. The cable itself comes through the stop to the throttle arm on the carb.

Like I said, not as pretty, but it works! Haven't yet run it enough to know for sure, but with the cables completely free to move with the carbs, it should be entirely immune to heat expansion/contraction issues.

J

I made a little splitter bracket from a piece of an angle shelf mounting bracket. Then we mounted a piece of angle iron in the middle of the engine in line with the throttle cable. In the angle iron, I put a couple of threaded holes for bicycle barrel adjusters, then a pair of bicycle brake cables to the carbs. I had a couple of transition pieces machined to go between the carbs and the manifolds with a stop for the cable housing. Needed stiffer than stock return springs to pull the cables back to idle, but other than that it works exactly as planned.

Here are some pics . . . In this first one, just between the blue coil and the two red plug wires you can see the throttle cable coming in from the left to the splitter piece, and then the piece of angle steel coming up from the middle of the engine for mounting the barrel adjusters for the cables. At some point, I’ll need to pretty up the edges/corners of the angle piece and get some paint on it. . .

This next pic is a closeup of the same spot. Here you can make out the barrel adjusters (just behind the plug wires) for balancing/synchronizing the two carbs so their throttle plates are open the same amount and they both draw the same air mid throttle. . .

Finally, the transition piece: The shiny aluminum piece in the middle is it. You can just barely see the bicycle brake cable housing coming in from the back to the stop at the lower left of the transition piece. The cable itself comes through the stop to the throttle arm on the carb.

Like I said, not as pretty, but it works! Haven't yet run it enough to know for sure, but with the cables completely free to move with the carbs, it should be entirely immune to heat expansion/contraction issues.

J

- Piledriver

- Moderator

- Posts: 22771

- Joined: Sat Feb 16, 2002 12:01 am

jjjtttggg, nice work, but I'm pretty sure you are going to need a guided splitter or you will have sync issues.

Simply having the 2 cables and sheaths physically clamped together in one hole would probably work...

It will still probably work better than a hexbar

Simply having the 2 cables and sheaths physically clamped together in one hole would probably work...

It will still probably work better than a hexbar

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

The Fix

- Posts: 168

- Joined: Thu Mar 17, 2005 9:25 pm

Re: Project---Split cable pull linkage

Can anyone give us an update on this, it looks like I need to be doing one of these. Any pics of finished system?

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

Re: Project---Split cable pull linkage

I'll let you know tonight.... I finally installed my engine on the pan and worked out the pedal to engine scheme. Hope it works

pete

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

Re: Project---Split cable pull linkage

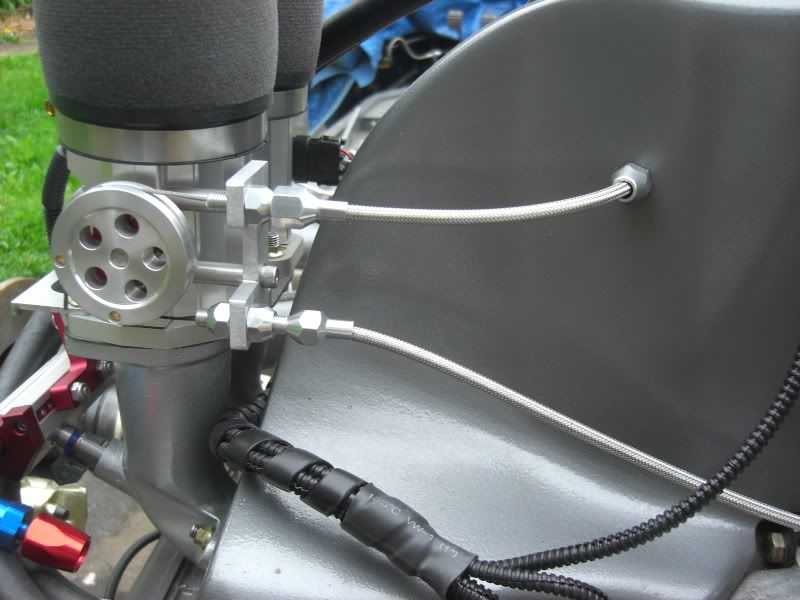

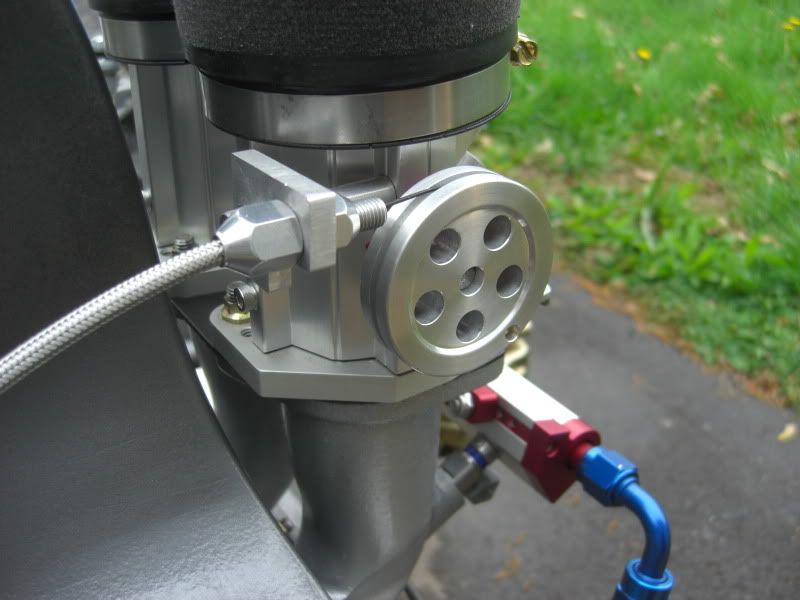

Here are some shots of my completed cable setup. These are Extrudabody tb's ( I got them real cheap). I also made a Dellorto version of this cable setup. The Dell's use the same wheels, but a different bracket system. I would like to make a Weber version, but, I don't have any weber carbs

The trickiest part was to make it easy running the cable from the pedal to the tb/carb...this little device, next to the bowden tube, did the trick....

Now I can run the cable all the way thru, with just a bit of help at the tb/carb.

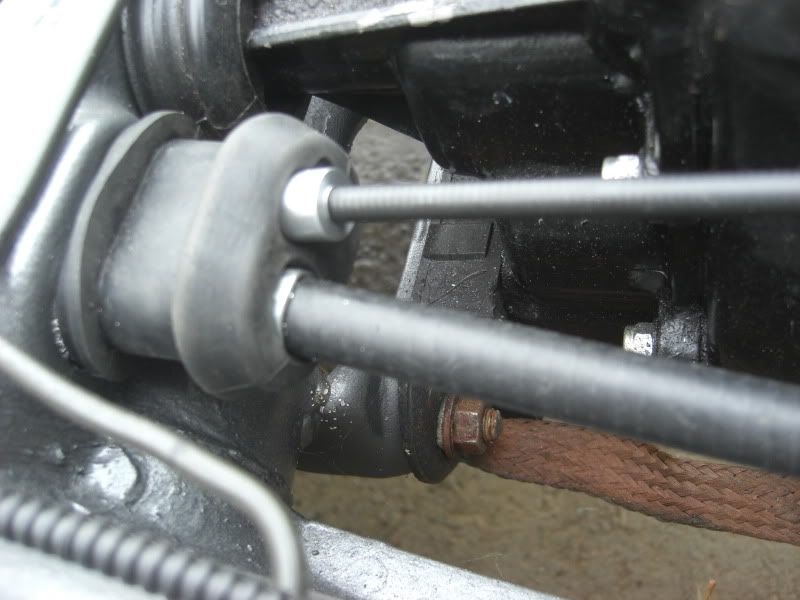

Here is the pedal setup. I have a real nice heim joint for this and I would swage the cable, but, I lent out my hydraulic crimper. I'll see how long this will last

After I installed the cable, I was happy to see how freely the cable moved. When I would pull on the cable at the back end and let go, the weight of the pedal would still go to the floor on it's own. I was a little concerned about the bends, but, they are not an issue.

I tried a bunch of cables and found that I would need to use two different types of cables, one for the pedal and another type between the tb/carb's. I even tried Kevlar cord and was really impressed with it, but, I was a little concerned with it's durability. The cable housings are teflon lined. Another thing that is nice, is adjusting the tb/carbs and pedal. This is done with adjusters on the driver side.

So how does it feel....... I like it. It feels responsive and quick, but, I will know better when this engine is finally running. .........and I'm on vacation the next two weeks, with a small honey do list........keeping my figers crossed

The trickiest part was to make it easy running the cable from the pedal to the tb/carb...this little device, next to the bowden tube, did the trick....

Now I can run the cable all the way thru, with just a bit of help at the tb/carb.

Here is the pedal setup. I have a real nice heim joint for this and I would swage the cable, but, I lent out my hydraulic crimper. I'll see how long this will last

After I installed the cable, I was happy to see how freely the cable moved. When I would pull on the cable at the back end and let go, the weight of the pedal would still go to the floor on it's own. I was a little concerned about the bends, but, they are not an issue.

I tried a bunch of cables and found that I would need to use two different types of cables, one for the pedal and another type between the tb/carb's. I even tried Kevlar cord and was really impressed with it, but, I was a little concerned with it's durability. The cable housings are teflon lined. Another thing that is nice, is adjusting the tb/carbs and pedal. This is done with adjusters on the driver side.

So how does it feel....... I like it. It feels responsive and quick, but, I will know better when this engine is finally running. .........and I'm on vacation the next two weeks, with a small honey do list........keeping my figers crossed

pete

- Piledriver

- Moderator

- Posts: 22771

- Joined: Sat Feb 16, 2002 12:01 am

Re: Project---Split cable pull linkage

Beautiful!

The Dell setup will fit on Webers, bracket just needs ~3-4mm spacing up to align cable to pulley.

(slight shaft position difference? I don't have Dells to verify)

The Dell setup will fit on Webers, bracket just needs ~3-4mm spacing up to align cable to pulley.

(slight shaft position difference? I don't have Dells to verify)

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

The Fix

- Posts: 168

- Joined: Thu Mar 17, 2005 9:25 pm

Re: Project---Split cable pull linkage

Looks great, I have Webbers on my motor and would be willing to help test!

-

trapnm

- Posts: 102

- Joined: Sat Oct 22, 2005 6:20 pm

Re: Project---Split cable pull linkage

Brilliant...Jake where are you at with one of these?

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

Re: Project---Split cable pull linkage

I've sent Jake a proto type some time ago, but haven't heard a word since. I tried a few shops to have parts made, but, they insist on some fancy drawings or a file. Hell, I do most of this stuff of the top of my head and my drawings are simple scratches on some note pads

I may start making some finished units and for the cost of parts, give them out to folks to try out and give me feed back. This may be this old mans delusion after all and not be worth the time and effort

I may start making some finished units and for the cost of parts, give them out to folks to try out and give me feed back. This may be this old mans delusion after all and not be worth the time and effort

pete

-

The Fix

- Posts: 168

- Joined: Thu Mar 17, 2005 9:25 pm

Re: Project---Split cable pull linkage

CHECK YOUR PMSslowtwitch wrote:I've sent Jake a proto type some time ago, but haven't heard a word since. I tried a few shops to have parts made, but, they insist on some fancy drawings or a file. Hell, I do most of this stuff of the top of my head and my drawings are simple scratches on some note pads

I may start making some finished units and for the cost of parts, give them out to folks to try out and give me feed back. This may be this old mans delusion after all and not be worth the time and effort

- fusername

- Posts: 6806

- Joined: Sun Jan 28, 2007 11:26 am

Re: Project---Split cable pull linkage

yeah, I have faith in folks when I sell stuff but it often comes back to bite. that said if you do do this, I have a set of dells that need a better linkage bad, and would happily document my experience. I hate my hex bar.slowtwitch wrote: I may start making some finished units and for the cost of parts, give them out to folks to try out and give me feed back. This may be this old mans delusion after all and not be worth the time and effort

give a man a watch and he'll allways know what time it is. give him two and he can never be sure again.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

- RonW

- Posts: 544

- Joined: Tue Jan 03, 2006 8:31 am

Re: Project---Split cable pull linkage

pete,slowtwitch wrote:I've sent Jake a proto type some time ago, but haven't heard a word since. I tried a few shops to have parts made, but, they insist on some fancy drawings or a file. Hell, I do most of this stuff of the top of my head and my drawings are simple scratches on some note pads

I may start making some finished units and for the cost of parts, give them out to folks to try out and give me feed back. This may be this old mans delusion after all and not be worth the time and effort

i'll beta test a set for ya!