Step by Step; 1700 carb to EFI (future to 2054)

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Step by Step; 1700 carb to EFI (future to 2054)

Currently building and planning some stuff for my '72 Baywindow engine;

First up, I will convert the tired 1700cc to EFI.

This is my first venture into the EFI/EFI tuning, so what better than use and abuse a tired 1700.

In general, this is what I am planning:

- should not look like a racing engine

- stock cooling

- 2L FI intake plenum

- intake runners from 914 FI engine

- choose the budget-friendly options where possible

- do as much as possible at home / by myself

First up, I will convert the tired 1700cc to EFI.

This is my first venture into the EFI/EFI tuning, so what better than use and abuse a tired 1700.

In general, this is what I am planning:

- should not look like a racing engine

- stock cooling

- 2L FI intake plenum

- intake runners from 914 FI engine

- choose the budget-friendly options where possible

- do as much as possible at home / by myself

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Step by Step; 1700 carb to EFI (future to 2054)

As I am at home now on parental leave for my December born daughter, I had a lot of time to plan/do some stuff while she was sleeping during the days.

My baywindow:

My baywindow:

Last edited by larsje on Thu Jun 21, 2018 6:17 am, edited 2 times in total.

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Step by Step; 1700 carb to EFI (future to 2054)

I modified a TB from a FI engine

- 52 mm throttle plate (from a DBW throttle body from a 2014 VW Golf)

- ball bearings

- custom shaft

- TPS adapter plate

- Bosch TPS

- 52 mm throttle plate (from a DBW throttle body from a 2014 VW Golf)

- ball bearings

- custom shaft

- TPS adapter plate

- Bosch TPS

Last edited by larsje on Thu Jun 21, 2018 6:19 am, edited 1 time in total.

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Step by Step; 1700 carb to EFI (future to 2054)

Custom made exhaust

took an old Ahnendorp header (mild steel, all rusted up) and fitted a CSP stainless damper box.

Also fitted EGO sensor.

Currently running innovate, but will be run by ECU in the future

took an old Ahnendorp header (mild steel, all rusted up) and fitted a CSP stainless damper box.

Also fitted EGO sensor.

Currently running innovate, but will be run by ECU in the future

Last edited by larsje on Thu Jun 21, 2018 6:45 am, edited 1 time in total.

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Step by Step; 1700 carb to EFI (future to 2054)

For the Engine management I will use a ECUmaster EMU Classic ECU.

I chose this ECU for several reasons;

- cost is about the same as a pre-built Megasquirt

- built in EGO sensor controller

- support by dealer , manufacturer and community

A lot of features I do not need (for now) but are cool to play with in the future (e.g. 2x EGT sensor controller built in)

Because it is a conversion from carburetors to EFI, i need to make a new wiring harness, so I made a layout in PowerPoint.

I will use a pigtail wiring harness from ECUmaster to begin with.

IAC will probably be skipped

Trigger wheel and sensor i got from Germany, and will fit between the case and cooling fan.

Not sure about the sensor tough, as it does not look like the typical TDC sensor. It has 2 wires so must be a VR sensor.

Anyone experienced with this type of sensor?

I chose this ECU for several reasons;

- cost is about the same as a pre-built Megasquirt

- built in EGO sensor controller

- support by dealer , manufacturer and community

A lot of features I do not need (for now) but are cool to play with in the future (e.g. 2x EGT sensor controller built in)

Because it is a conversion from carburetors to EFI, i need to make a new wiring harness, so I made a layout in PowerPoint.

I will use a pigtail wiring harness from ECUmaster to begin with.

IAC will probably be skipped

Trigger wheel and sensor i got from Germany, and will fit between the case and cooling fan.

Not sure about the sensor tough, as it does not look like the typical TDC sensor. It has 2 wires so must be a VR sensor.

Anyone experienced with this type of sensor?

- raygreenwood

- Posts: 11895

- Joined: Wed Jan 22, 2003 12:01 am

Re: Step by Step; 1700 carb to EFI (future to 2054)

You should dump the 2.0L 914 plenum. It has worse flow than ANY of the side entrance TB's ranging from 1.7L 411/412/914 to 1.8 and 2.0L bus.

The 1.7L of course is too small for a 2056...but a 1.8L 412, 914 or bus plenum will work fine. A 2.0L bus plenum will work very well.

The problem with the 2.0L 914 set up is that the incoming air has to make many 90* turns per second in four different directions to hit the runners...and has no appreciable distance between TB and the floor of the plenum. It takes a distance of between 5X and 7X (or more) of the diameter of the runner...behind the TB plate...to dissipate the nasty plume of turbulence created by the throttle plate. You do not have that room on the 914 2.0L plenum....and you get another nasty knot of turbulence due to that plume of TB turbulence having to make 90* turns just inside as it exits the plenum.

The 1.7L, 1.8L and 2.0L bus plenums are a MUCH better design. They enter offset and bounce the TB plume off the curve section just opposite the TB which re-centers the plume and straightens it out a bit. And...yes....I have actually visually seen this back in the late 90's using smoke testing with a tuboscope through the cold start valve hole. It was amazing.....wish I had video. Keep meaning to reproduce this at some point.

The TB in your picture should bolt right up to any of those. You simply need to take a muffler expander and work the inlet hole slightly to match teh larger TB.

If you scroll down in this thread...you can see the plenum pictures with the expanded TB opening near the very end.

https://www.thesamba.com/vw/forum/viewt ... p?t=683230

Ray

The 1.7L of course is too small for a 2056...but a 1.8L 412, 914 or bus plenum will work fine. A 2.0L bus plenum will work very well.

The problem with the 2.0L 914 set up is that the incoming air has to make many 90* turns per second in four different directions to hit the runners...and has no appreciable distance between TB and the floor of the plenum. It takes a distance of between 5X and 7X (or more) of the diameter of the runner...behind the TB plate...to dissipate the nasty plume of turbulence created by the throttle plate. You do not have that room on the 914 2.0L plenum....and you get another nasty knot of turbulence due to that plume of TB turbulence having to make 90* turns just inside as it exits the plenum.

The 1.7L, 1.8L and 2.0L bus plenums are a MUCH better design. They enter offset and bounce the TB plume off the curve section just opposite the TB which re-centers the plume and straightens it out a bit. And...yes....I have actually visually seen this back in the late 90's using smoke testing with a tuboscope through the cold start valve hole. It was amazing.....wish I had video. Keep meaning to reproduce this at some point.

The TB in your picture should bolt right up to any of those. You simply need to take a muffler expander and work the inlet hole slightly to match teh larger TB.

If you scroll down in this thread...you can see the plenum pictures with the expanded TB opening near the very end.

https://www.thesamba.com/vw/forum/viewt ... p?t=683230

Ray

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

Thats why i have a 2L (bus) plenum, but are going to use the 914 runners (bigger pipe diameter, no step in the pipe after the connection to the plenum)raygreenwood wrote:You should dump the 2.0L 914 plenum. It has worse flow than ANY of the side entrance TB's ranging from 1.7L 411/412/914 to 1.8 and 2.0L bus.

The 1.7L of course is too small for a 2056...but a 1.8L 412, 914 or bus plenum will work fine. A 2.0L bus plenum will work very well.

The problem with the 2.0L 914 set up is that the incoming air has to make many 90* turns per second in four different directions to hit the runners...and has no appreciable distance between TB and the floor of the plenum. It takes a distance of between 5X and 7X (or more) of the diameter of the runner...behind the TB plate...to dissipate the nasty plume of turbulence created by the throttle plate. You do not have that room on the 914 2.0L plenum....and you get another nasty knot of turbulence due to that plume of TB turbulence having to make 90* turns just inside as it exits the plenum.

The 1.7L, 1.8L and 2.0L bus plenums are a MUCH better design. They enter offset and bounce the TB plume off the curve section just opposite the TB which re-centers the plume and straightens it out a bit. And...yes....I have actually visually seen this back in the late 90's using smoke testing with a tuboscope through the cold start valve hole. It was amazing.....wish I had video. Keep meaning to reproduce this at some point.

The TB in your picture should bolt right up to any of those. You simply need to take a muffler expander and work the inlet hole slightly to match teh larger TB.

If you scroll down in this thread...you can see the plenum pictures with the expanded TB opening near the very end.

https://www.thesamba.com/vw/forum/viewt ... p?t=683230

Ray

- raygreenwood

- Posts: 11895

- Joined: Wed Jan 22, 2003 12:01 am

Re: Step by Step; 1700 carb to EFI (future to 2054)

Oh!...cool! Somehow I missed that part. That will be a nice set up!

Ray

Ray

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

Small update (not much time available right now);

Removed the EGR (Exhaust Gas Recirculation) piping in the plenum and closed the EGR connection on the plenum. And a nice coat of black.

Next steps; fuel system

Starting from the tank;

It will get a POR 15 treatment and I will braze a stainless AN 8 fitting to it (just before coating, but after cleaning/ rust removal)

From there i will go to the fuel pump with a “push on” style hose, then to the fuel filter.

Need to make a bracket for pump/ filter.

After that I need to modify the runners; shorten (the plenum is wider than the plenum to which the runners originally belong to)

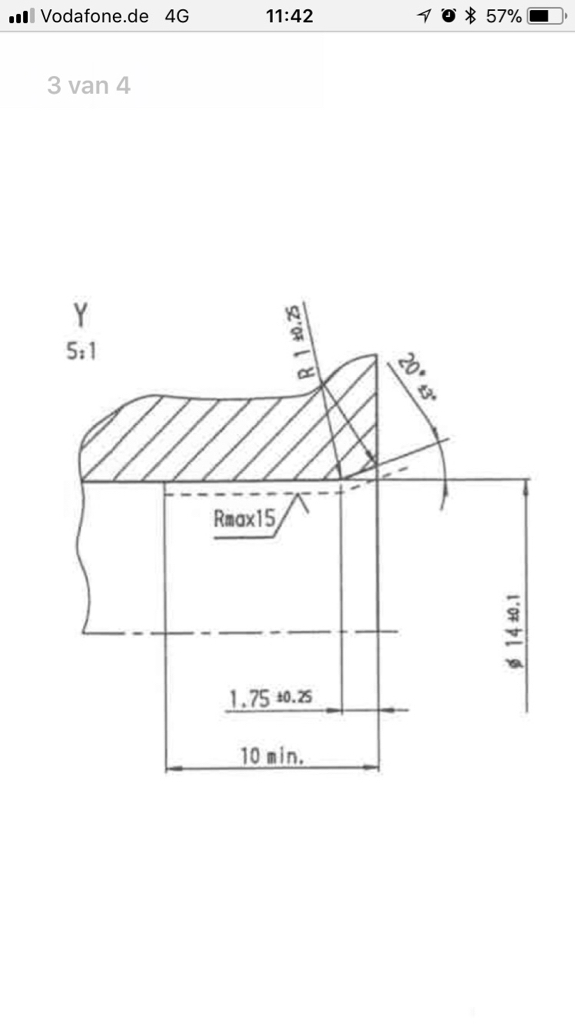

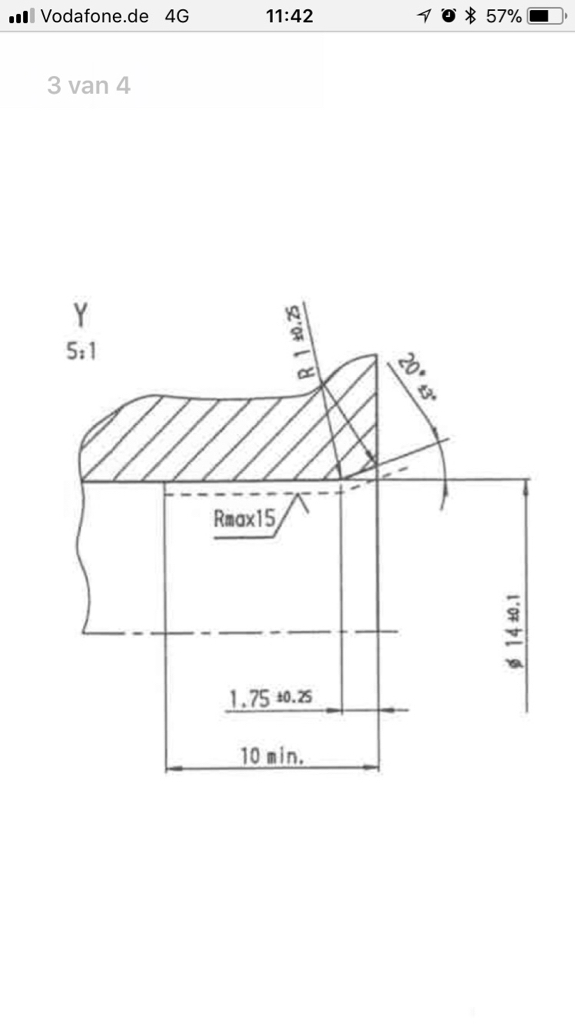

And drill for 14 mm modern injector seats.

Still need to play with the angle on the drill press, will be drilling from 10 mm originally to the required seat, last bit will be done with a reamer to get the required surface quality.

Removed the EGR (Exhaust Gas Recirculation) piping in the plenum and closed the EGR connection on the plenum. And a nice coat of black.

Next steps; fuel system

Starting from the tank;

It will get a POR 15 treatment and I will braze a stainless AN 8 fitting to it (just before coating, but after cleaning/ rust removal)

From there i will go to the fuel pump with a “push on” style hose, then to the fuel filter.

Need to make a bracket for pump/ filter.

After that I need to modify the runners; shorten (the plenum is wider than the plenum to which the runners originally belong to)

And drill for 14 mm modern injector seats.

Still need to play with the angle on the drill press, will be drilling from 10 mm originally to the required seat, last bit will be done with a reamer to get the required surface quality.

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

One last drive with the 1700 to the bugshow (Spa-Francorchamps, BE)

The obligatory “before” picture;

And the carburetors are out!

I new that i needed to re-route the throttle cable, but when fitting the plenum and the throttle body I found that the TB-arm is almost on the sheet metal. Luckily i found an “injection” rear sheet metal in my stack (bought a completely disassembled, but incomplete 2L engine a while back)

Next steps;

- figure out throttle cable routing

- make a rubber grommet to fill the cable hole (as the original rubbers are not available)

- close the warm air suction hole on the rear of the #1 cilinder sheet metal

The obligatory “before” picture;

And the carburetors are out!

I new that i needed to re-route the throttle cable, but when fitting the plenum and the throttle body I found that the TB-arm is almost on the sheet metal. Luckily i found an “injection” rear sheet metal in my stack (bought a completely disassembled, but incomplete 2L engine a while back)

Next steps;

- figure out throttle cable routing

- make a rubber grommet to fill the cable hole (as the original rubbers are not available)

- close the warm air suction hole on the rear of the #1 cilinder sheet metal

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

And I decided that as soon as possible after the efi conversion, i will build the bigger engine. As the oil usage of the 1700 is huge!

(0,65L on 250 km; to Spa and back and drive a few laps around)

Got multiple complaints from my friends who were driving behind me

Verzonden vanaf mijn iPhone met Tapatalk

(0,65L on 250 km; to Spa and back and drive a few laps around)

Got multiple complaints from my friends who were driving behind me

Verzonden vanaf mijn iPhone met Tapatalk

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

So, drilling the 1.7 914 runners for 14 mm injectors does not work.

The wall thickness gets too small for a decent o-ring seat.

Also I was not happy with the fuel rail having 3 mm higher spacing than the injector positions.

To solve above issues, I roughly modeled the manifold and came up wit following solutions;

The manifolds will get bushings, rail cut and a sleeve brazed on. The bracket will work left-right (flip it over).

In the meantime that the bushings are getting made, I’m blasting the manifolds clean for paint.

Since i can not find a paint code for the manifolds (and no other color comes close, i will have to get the paint measured. Will take the “insulation rack” to the paint guy for color soon as its less battered than the manifolds and the same color.

Verzonden vanaf mijn iPhone met Tapatalk

The wall thickness gets too small for a decent o-ring seat.

Also I was not happy with the fuel rail having 3 mm higher spacing than the injector positions.

To solve above issues, I roughly modeled the manifold and came up wit following solutions;

The manifolds will get bushings, rail cut and a sleeve brazed on. The bracket will work left-right (flip it over).

In the meantime that the bushings are getting made, I’m blasting the manifolds clean for paint.

Since i can not find a paint code for the manifolds (and no other color comes close, i will have to get the paint measured. Will take the “insulation rack” to the paint guy for color soon as its less battered than the manifolds and the same color.

Verzonden vanaf mijn iPhone met Tapatalk

- GuruX

- Posts: 9

- Joined: Wed Jun 13, 2018 1:18 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

So happy I found your thread!

I'm doing pretty much the same thing, with Type 4 1800 cc in my late bay. Engine code is AP. Conversion for modern fuel injection.

So, things we've got in common:

1. EFI in a DIY way.

2. Modern injectors in same place as the old ones.

3. Dual carbs removed

4. DIY fuel rail with parts from other cars

5. Conversion with a 2.0 bus plenum and Bosch TPS.

Things I'm doing differently.

1. ECU, I'm using a Speeduino

2. EV6 injectors. I have 3D printed an adapter. I'd be happy to send you a set if you need them.

3. Plans on fitting a flexifuel sensor for running on both E85 and petrol.

4. Trigger wheel from The Dub Shop

5. Surge tank

6. No building for performance. I just don't know how to use carbs, electronics suits me better.

7. Different intake runners.

My project thread here is a bit thin. I have spread out over the internet, so here are a couple of links to my build.

Shoptalk forums: viewtopic.php?f=14&t=150578&sid=2d87f45 ... 283f068e5d

Speeduino forums: http://speeduino.com/forum/viewtopic.php?t=1468

TheSamba: https://www.thesamba.com/vw/forum/viewt ... 3f8dd35ac3

I think we could help each other out with some parts of the build. Right now I'm thinking about the throttle cable routing.

I'm doing pretty much the same thing, with Type 4 1800 cc in my late bay. Engine code is AP. Conversion for modern fuel injection.

So, things we've got in common:

1. EFI in a DIY way.

2. Modern injectors in same place as the old ones.

3. Dual carbs removed

4. DIY fuel rail with parts from other cars

5. Conversion with a 2.0 bus plenum and Bosch TPS.

Things I'm doing differently.

1. ECU, I'm using a Speeduino

2. EV6 injectors. I have 3D printed an adapter. I'd be happy to send you a set if you need them.

3. Plans on fitting a flexifuel sensor for running on both E85 and petrol.

4. Trigger wheel from The Dub Shop

5. Surge tank

6. No building for performance. I just don't know how to use carbs, electronics suits me better.

7. Different intake runners.

My project thread here is a bit thin. I have spread out over the internet, so here are a couple of links to my build.

Shoptalk forums: viewtopic.php?f=14&t=150578&sid=2d87f45 ... 283f068e5d

Speeduino forums: http://speeduino.com/forum/viewtopic.php?t=1468

TheSamba: https://www.thesamba.com/vw/forum/viewt ... 3f8dd35ac3

I think we could help each other out with some parts of the build. Right now I'm thinking about the throttle cable routing.

- Clatter

- Posts: 2034

- Joined: Sun Apr 28, 2002 1:01 am

Re: Step by Step; 1700 carb to EFI (future to 2054)

Love this build, even though i have nothing really to add.

Been contemplating converting my L-Jet bus to something modern,

So am following along with much interest.

My build would have to visually appear as stock for smog reasons.

Hoping they might not notice the crank trigger hidden behind the fan,

or that the AFM was just a gutted shell..

Seems that things like fuel tank and rails, etc. would make the conversion much easier vs. carbs no doubt.

Might be a shortcut to find a factory FI tank somewhere?

Have heard that suction/discharge, and well as venting, can be a challenge,

And VW solved these things well with the factory fuel tanks.

FWIW.

Thanks for taking the time to write this all up.

Been contemplating converting my L-Jet bus to something modern,

So am following along with much interest.

My build would have to visually appear as stock for smog reasons.

Hoping they might not notice the crank trigger hidden behind the fan,

or that the AFM was just a gutted shell..

Seems that things like fuel tank and rails, etc. would make the conversion much easier vs. carbs no doubt.

Might be a shortcut to find a factory FI tank somewhere?

Have heard that suction/discharge, and well as venting, can be a challenge,

And VW solved these things well with the factory fuel tanks.

FWIW.

Thanks for taking the time to write this all up.

Speedier than a Fasting Bullet!

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

Beginners' how-to Type 4 build thread ---> http://shoptalkforums.com/viewtopic.php?f=1&t=145853

-

larsje

- Posts: 24

- Joined: Fri May 15, 2009 1:06 pm

Re: Step by Step; 1700 carb to EFI (future to 2054)

Hi GuruX, nice build you have yourself! Going a lot quicker than I am.GuruX wrote: ↑Thu May 09, 2019 11:29 am So happy I found your thread!

I'm doing pretty much the same thing, with Type 4 1800 cc in my late bay. Engine code is AP. Conversion for modern fuel injection.

So, things we've got in common:

1. EFI in a DIY way.

2. Modern injectors in same place as the old ones.

3. Dual carbs removed

4. DIY fuel rail with parts from other cars

5. Conversion with a 2.0 bus plenum and Bosch TPS.

Things I'm doing differently.

1. ECU, I'm using a Speeduino

2. EV6 injectors. I have 3D printed an adapter. I'd be happy to send you a set if you need them.

3. Plans on fitting a flexifuel sensor for running on both E85 and petrol.

4. Trigger wheel from The Dub Shop

5. Surge tank

6. No building for performance. I just don't know how to use carbs, electronics suits me better.

7. Different intake runners.

My project thread here is a bit thin. I have spread out over the internet, so here are a couple of links to my build.

Shoptalk forums: viewtopic.php?f=14&t=150578&sid=2d87f45 ... 283f068e5d

Speeduino forums: http://speeduino.com/forum/viewtopic.php?t=1468

TheSamba: https://www.thesamba.com/vw/forum/viewt ... 3f8dd35ac3

I think we could help each other out with some parts of the build. Right now I'm thinking about the throttle cable routing.

I will follow you on youtube/facebook to see your progress!

What fuel rail are you using as a base? Does it have 85 mm (and not the 88 mm from the Audi/VW engines)?

I hate setting carbs too... I understand the physics behind it, but somehow it is still magic/art to me instead of science.

It looks like you are using a 1.7L plenum, right? I did some calculations and seems like the 2L plenum matches the 2L engine very well (what a surprize, the VW engineers prob. made the same calculation in the 70s) Because i am upgrading the engine to 2054cc later on, i chose to go that way.

All the things you are doing differently, I considered also before;

1. I looked at MS/Speeduino but want warranty/support from a "real" company and not only from a community, however the ECUMaster community is very active as well.

2. I considered using EV1 injectors, they can be used with the original clamps and converted to the axial sealing (with the square rings) and the hose feed that the original injection uses. There is a guy in the Netherlands (where i am from) that did this, but the forum he posted this on is offline unfortunately (keversite.nl). If I remember correctly, he used a refurbishment set for the original injectors, cut off plastic from the EV1 injectors and that was it. You might be able to use the square rings as well if you cut off the plastic from the EV6 and use your printed adapter.

Because of my day-to-day work (I design engines for a living) I could not get myself to use the O-ring axially/in the original chamfer, as for me, such things need to be to "spec" from the manufacturer (Bosch).

3. My fuel system will be Ethanol resistant, and the ECU can handle flexfuel as well. Unfortunately E85/E100 is very poorly available in my area (at least 40km driving) so will not do this yet.

4. I like the dubshop sensor and bracket over the one i am using. As soon as mine causes any trouble, I will design a bracket for such a sensor myself and use that instead.

5. Packaging a surge thank with internal fuel pump below my car is difficult (it is lowered). Also i do not see very big advantages, you still need to vent it into the tank, so need 2 connections. And as it is a bus, i do not need the "cornering" advantage.

6. Not building for performance as well. Electronics is not my thing (its mechanics) but as said, carbs are not my friend either.

7. Intake runners look the same (1.7 914), but i can be mistaken.

Throttle cable routing is one of the next things on my list as well. but original injection bus routing should work..............

By the way, which material are you using for the 3D printed parts? I backed a Snapmaker 2 on Kickstarter just a few days ago, so hopefully at the end of the year I will be printing carparts.

Glad to share my thoughts, documentation and discussion helps any technical development. That is why i do it, so if anyone learns/profits from it for their own project it is a bonus!